A method for improving the anti-skid performance of polished tiles and polished tiles

A technology for polishing tiles and performance, applied in the method and polishing tiles, improving the anti-skid performance of polished tiles, can solve the problems of anti-skid, poor anti-fouling performance of polished tiles, complex methods of anti-skid tiles, etc., to simplify the production process and reduce production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

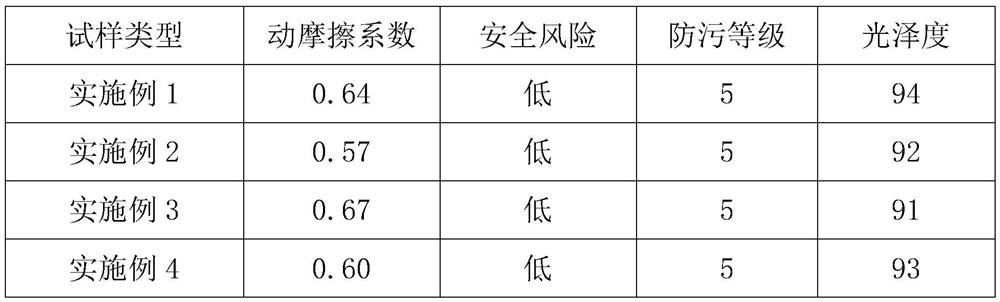

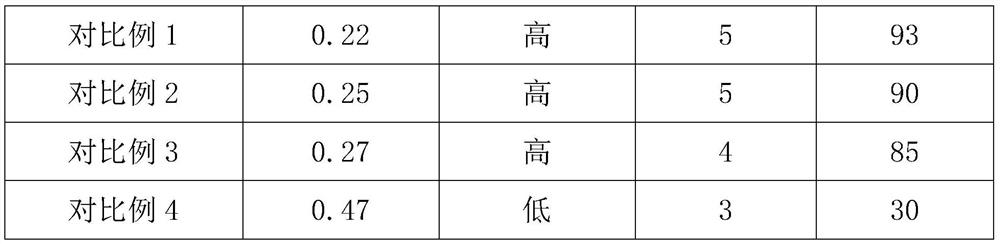

Examples

Embodiment 1

[0038] A method for improving the anti-skid performance of polished tiles, comprising the steps of:

[0039] Put the tiles in a nano polishing machine, polish the surface of the tiles, and raise the temperature of the tiles to 45°C; then use 1mL / cm 2 Drop anti-slip liquid on the surface of the tiles, and polish with 3 nylon pads; then use 1mL / cm 2 Add the anti-slip fixing solution to the surface of the tile, and polish it with 4 nylon pads; clean it with a wool wheel, and grind and polish it for 10 minutes to obtain an anti-slip polished tile.

[0040] Wherein, the anti-slip liquid is composed of the following mass fractions: 20% organic acid, 20% anti-slip synergist, 22% sodium dodecylbenzenesulfonate, 38% organic solvent; the anti-slip fixative consists of The composition of the following mass fractions: 30% cationic water-based polymer, 70% organic solvent.

Embodiment 2

[0042] A method for improving the anti-skid performance of polished tiles, comprising the steps of:

[0043] Put the tiles in a nano polishing machine, polish the surface of the tiles, and raise the temperature of the tiles to 55°C; then use 2mL / cm 2Drop anti-slip liquid on the surface of the tiles and polish with 4 nylon pads; in the case of not cleaning the tiles, use a dripping amount of 2mL / cm 2 Add non-slip fixing solution to the surface of the tiles, polish with 5 nylon pads; clean with a wool wheel, and grind and polish for 5 minutes to obtain non-slip polished tiles.

[0044] Wherein, the anti-slip liquid is composed of the following mass fractions: 1% organic acid, 30% anti-slip synergist, 25% sodium stearate, 44% organic solvent; the anti-slip fixative is composed of the following mass fractions: Composition: 32% cationic water-based polymer, 68% organic solvent.

Embodiment 3

[0046] A method for improving the anti-skid performance of polished tiles, comprising the steps of:

[0047] Put the tiles in a nano polishing machine, polish the surface of the tiles, and raise the temperature of the tiles to 40°C; then use 0.5mL / cm 2 Drop anti-slip liquid on the surface of the tiles, and use 4 wool wheels to polish; in the case of not cleaning the tiles, use 0.5mL / cm 2 Add the anti-slip fixing solution to the surface of the ceramic tile, and polish it with 5 wool wheels; clean it with the wool wheel, and grind and polish it for 3 minutes to obtain an anti-slip polished tile.

[0048] Wherein, the anti-slip liquid is composed of the following mass fractions: 25% organic acid, 25% anti-slip synergist, 20% sodium stearate, 30% organic solvent; the anti-slip fixative is composed of the following mass fractions: Composition: 34% cationic water-based polymer, 66% organic solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com