One-step formed light-weight cushioning composite outsole and preparation method thereof

A cushioning and lightweight technology, applied in the field of preparation of lightweight cushioning composite outsoles, can solve problems such as fluctuations in bonding effects and environmental pollution, and achieve the effects of avoiding pollution, reducing production costs, and ensuring bonding effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A preparation method for a one-time molding lightweight cushioning composite outsole, comprising the following steps:

[0039] In the first step, the raw materials of anti-slip rubber blocks, the raw materials of wear-resistant rubber blocks, and the raw materials of lightweight rubber blocks are respectively refined to obtain the refined anti-skid rubber block, the wear-resistant rubber block, and light rubber block of glue;

[0040] In the second step, put the rubber material of the refined anti-skid rubber block, the rubber material of the wear-resistant rubber block, and the rubber material of the lightweight rubber block on the corresponding positions of the bottom of the outsole, and vulcanize for 60-120 seconds. The vulcanization temperature is 150±5 degrees, the pressure is 10-12MPa, and then put the rubber material of the foamed rubber layer on the top of the bottom rubber material, and vulcanize for 480 seconds to 540 seconds, the curing temperature is 150±5 d...

Embodiment 1

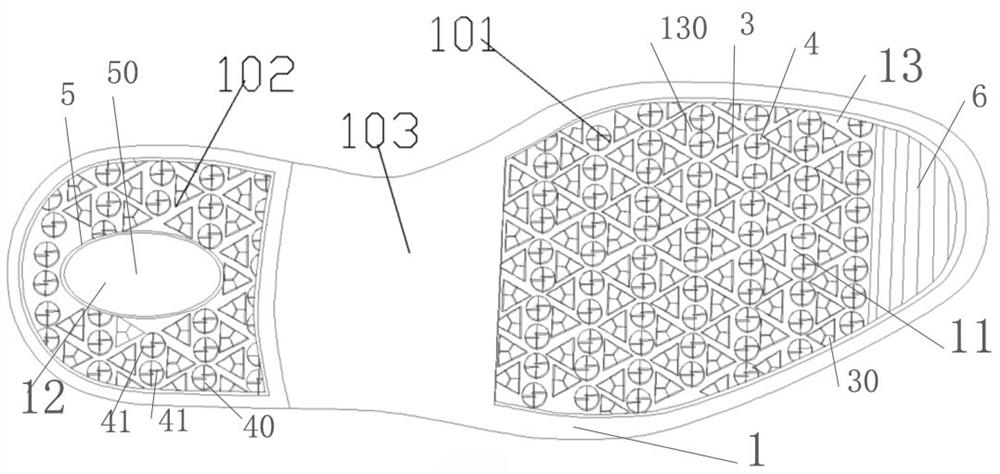

[0044] Such as figure 1 and figure 2 As shown, a one-time molded lightweight cushioning composite outsole includes a bottom layer 1 and a foam rubber layer 2 in the inner cavity of the bottom layer; the forefoot portion 11 of the bottom layer 1 is a non-slip rubber block 101, and the heel portion 12 of the bottom layer The wear-resistant rubber block 102 is connected by a lightweight rubber block 103 between the forefoot portion 11 and the heel portion 12 . The non-slip rubber block and the light rubber block are connected by vulcanization and cross-linking, and the wear-resistant rubber block and the light rubber block are connected by vulcanization and cross-linking; The foam rubber layers are connected by vulcanized crosslinks.

[0045] Anti-slip patterns 13 are provided on the bottom surfaces of the forefoot portion 11 and the heel portion 12 of the bottom layer.

[0046] The anti-slip pattern 13 includes unit patterns 130 arranged in an array on the bottom surface of ...

Embodiment 2

[0065] A one-time molded lightweight cushioning composite outsole, the difference from Example 1 is that the raised height of the triangular pattern and the circular pattern is 2mm, and the recessed depth of the groove I, groove II, and groove III is 2mm. The horizontal stripe groove 6 has a width of 1.3 mm and a depth of 2 mm.

[0066] The raw material of the non-slip rubber block is composed of two parts, the first part is composed of the following raw materials in parts by weight: 30 parts of natural rubber (NR), 12 parts of butadiene rubber (BR), 13 parts of solution polystyrene butadiene rubber (SSBR), 3 parts of active zinc oxide, 1 part of octadecanoic acid, 0.3 parts of N-isopropyl-N'-phenyl-p-phenylenediamine; 0.2 parts of 2,2,4-trimethyl-1,2-dihydroquinoline 30 parts of white carbon black, 2.5 parts of anti-slip agent NOVARES C10, 1 part of si-69 silane coupling agent, 1 part of polyethylene glycol.

[0067] The second part is the amount added on the basis of the f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com