Flexible mechanical grasping device and grabbing method thereof

A gripping device and mechanical technology, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of small applicable range, unreliability, and small applicable range, so as to improve the applicable range, operation level and operation efficiency, Guaranteed reliability and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

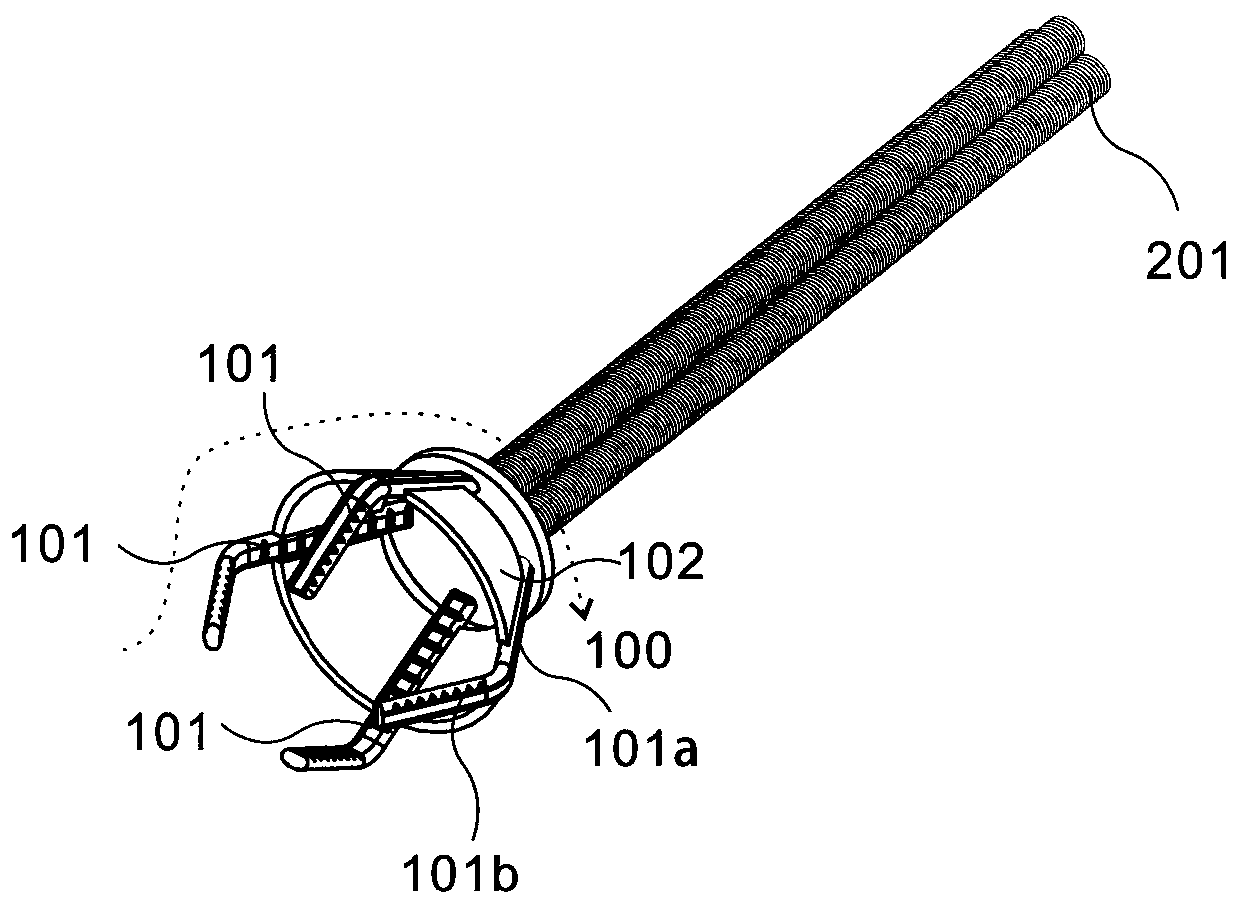

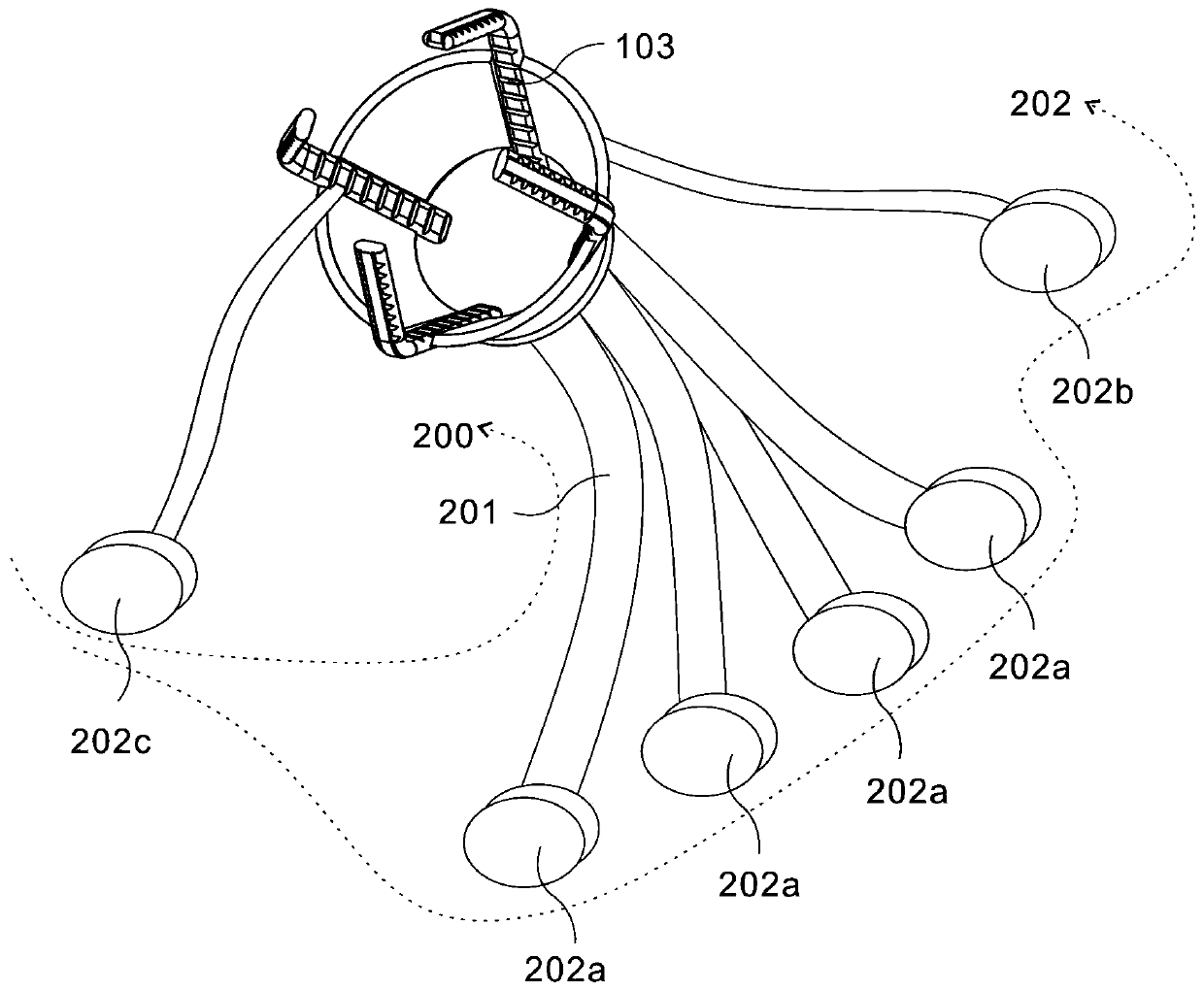

[0037] The present invention provides a flexible mechanical grasping device. In the first embodiment of the present invention, the main body of the flexible mechanical grasping device includes a grasping component 100 and a regulating component 200, and the regulating component 200 is connected to the grasping component 200. Components 100 are connected.

[0038] refer to Figure 1 ~ Figure 2 Specifically, the grabbing assembly 100 includes bending fingers 101 and an adsorption film 102, the adsorption film 102 is arranged between two of the bending fingers 101, and the bending fingers 101 are pumped and aired by the control assembly 200. Air intake, clamping and loosening the object to be taken, when the control assembly 200 draws air, the adsorption film 102 stretches and forms a negative pressure, and clings to the object to be taken.

[0039] Preferably, the knuckle of the bent finger 101 has a wrinkled texture, and the meaning of the wrinkle is the potential elongation l...

Embodiment 2

[0051] refer to Figure 1 ~ Figure 2 , in the second embodiment of the flexible mechanical grasping device provided by the present invention, this embodiment is different from the first embodiment in that: in this embodiment, the grasping component 100 also includes a surface film 103, the The surface film 103 is attached to the inner side of the bending finger 101; the surface film 103 is composed of a plurality of evenly distributed small squares, and the raised small squares are pressed against the object after inflation, and the The small square is under negative pressure.

[0052] Specifically, the main body of the flexible mechanical grasping device includes a grasping component 100 and a regulating component 200 , and the regulating component 200 is connected with the grasping component 100 .

[0053] The grasping component 100 includes a bending finger 101, an adsorption film 102 and a surface film 103, the adsorption film 102 is arranged between two of the bending fi...

Embodiment 3

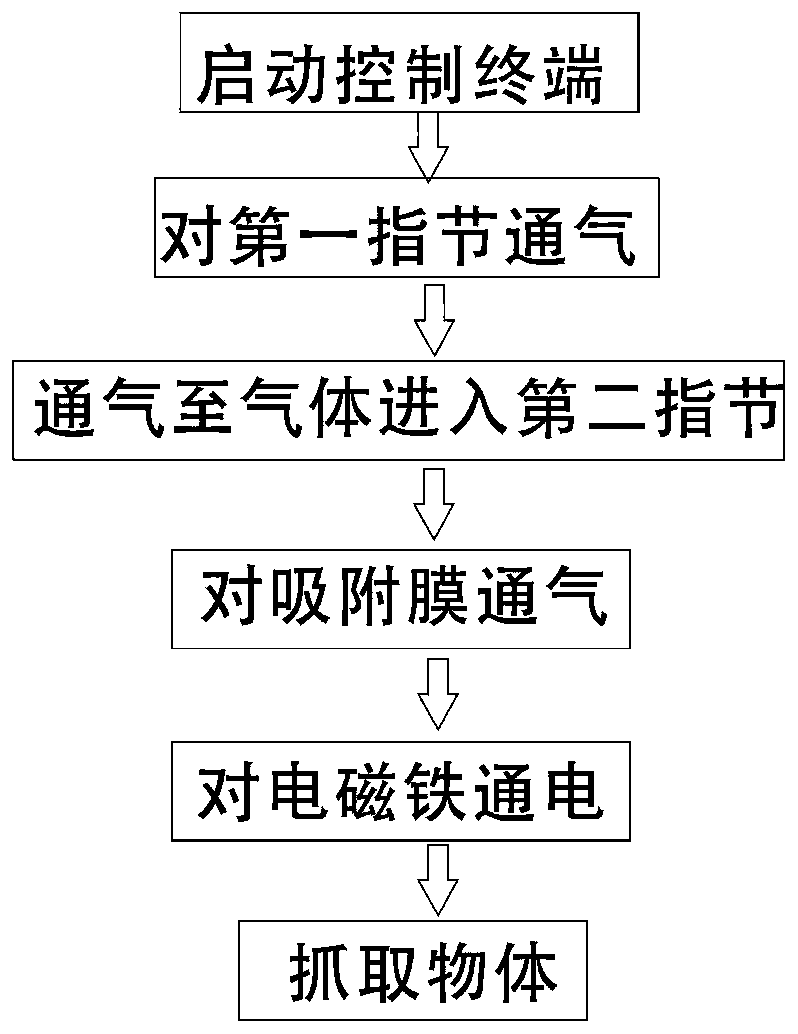

[0062] refer to Figure 1 ~ Figure 2 , in the third embodiment of the flexible mechanical gripping device provided by the present invention, this embodiment is different from the second embodiment in that: the second knuckle 101b is provided with an electromagnet, and after power is applied, the second finger The fingertips of the knuckles 101b form a magnetic field that attracts each other, and the second knuckles 101b gather together.

[0063] It should be noted that the size of the magnetism needs to be changed according to the weight and compression resistance of the clamped item, so as to avoid damage to the clamped item and unreliable clamping. At the same time, the energizing voltage of the magnetic size is manually adjusted.

[0064] All the other structures are similar to the second embodiment.

[0065] The working principle in this embodiment is: slowly open toward the first knuckle 101a, increase the ventilation volume, until the second knuckle 101b expands inward...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com