A device for manufacturing embedded holes in the inner frame of a ceramic photo frame

A ceramic phase and pre-buried hole technology, applied in the direction of manufacturing tools, supply devices, ceramic molding machines, etc., can solve problems such as roughness, inconvenient installation, and ceramic fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

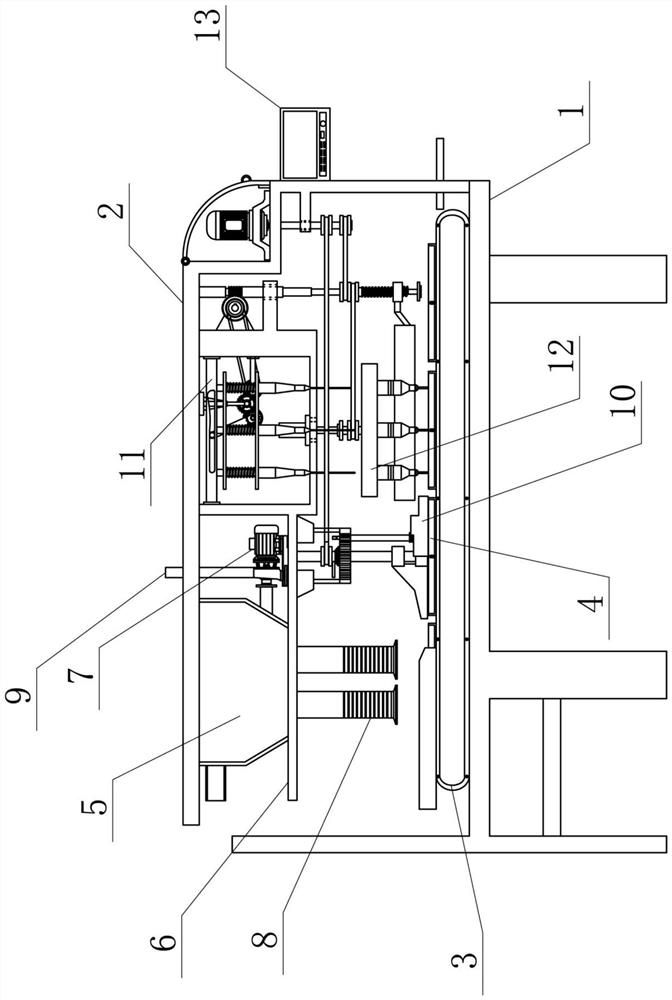

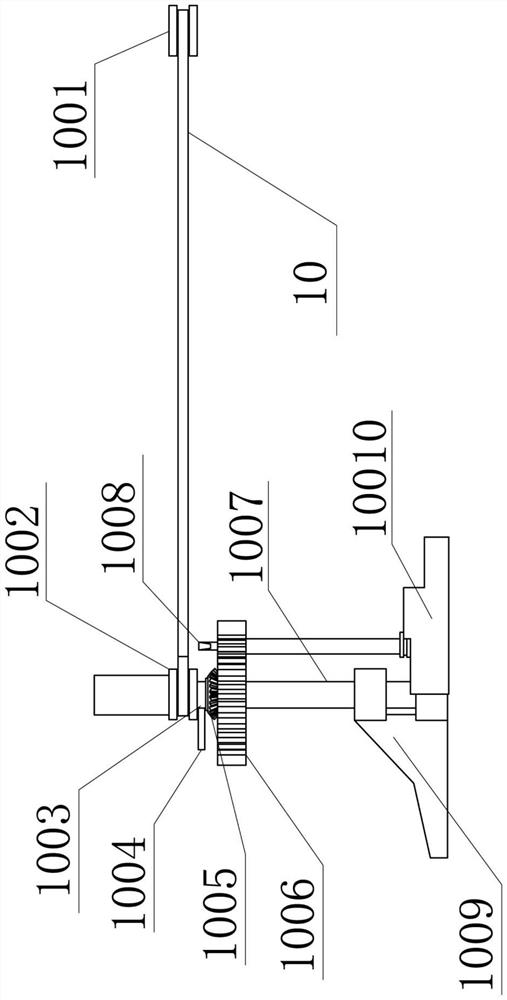

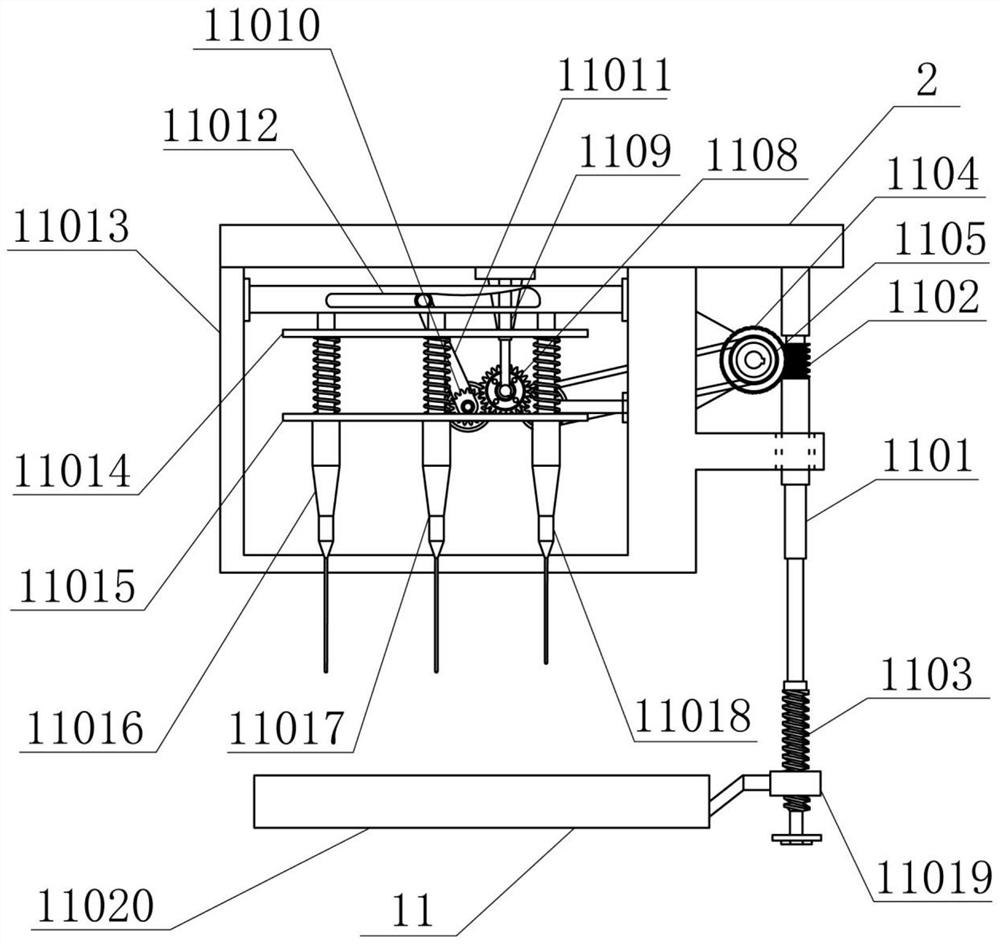

[0028] A device for manufacturing embedded holes in the inner frame of a ceramic photo frame, such as Figure 1-7 As shown, it includes a base 1, a support frame 2, a transmission mechanism 3, a ceramic photo frame mold 4, a lower material compartment 5, a first support plate 6, a feeding pump 7, a discharge pipe 8, a feed pipe 9, and a smoothing mechanism 10 , cleaning mechanism 11, punching mechanism 12 and control display screen 13; the right part of the top of the base 1 is welded with the support frame 2; the middle part of the top of the base 1 is provided with a transmission mechanism 3; the top left part of the support frame 2 is provided with an unloading cabin 5. The middle left part of the top of the support frame 2 is plugged with the feed pipe 9; the right part of the top end of the support frame 2 is provided with a hole cleaning mechanism 11; the front middle right part of the support frame 2 is provided with a punching mechanism 12, and the punching mechanism 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com