A process for recovering rubber granules using a recovery device for rubber granules

A recycling device and rubber recycling technology, which is applied in plastic recycling, mechanical material recycling, recycling technology, etc., can solve the problems of waste of rubber resources, environmental pollution, etc., reduce energy consumption and cost, avoid direct discharge, and ensure recycling efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

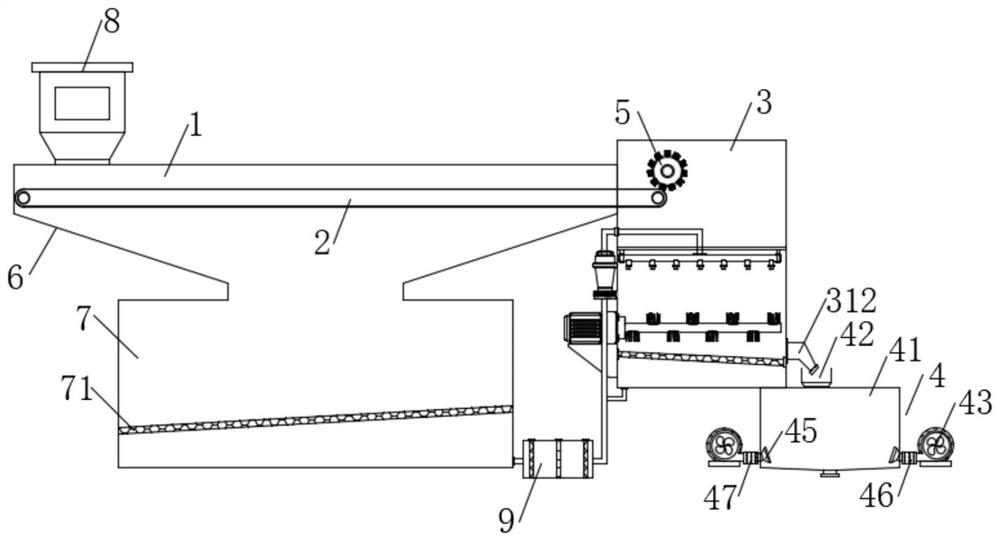

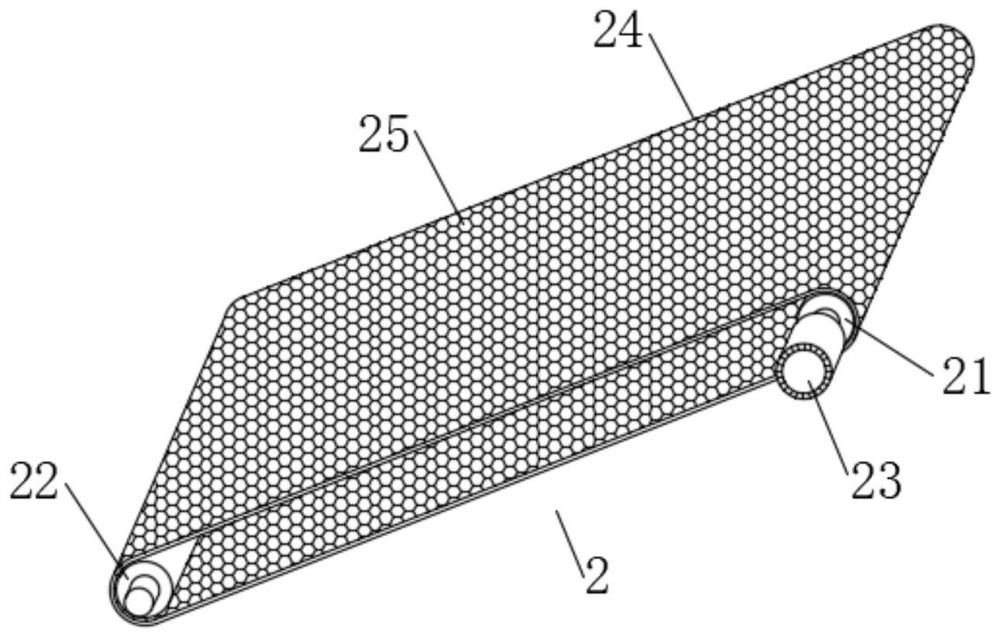

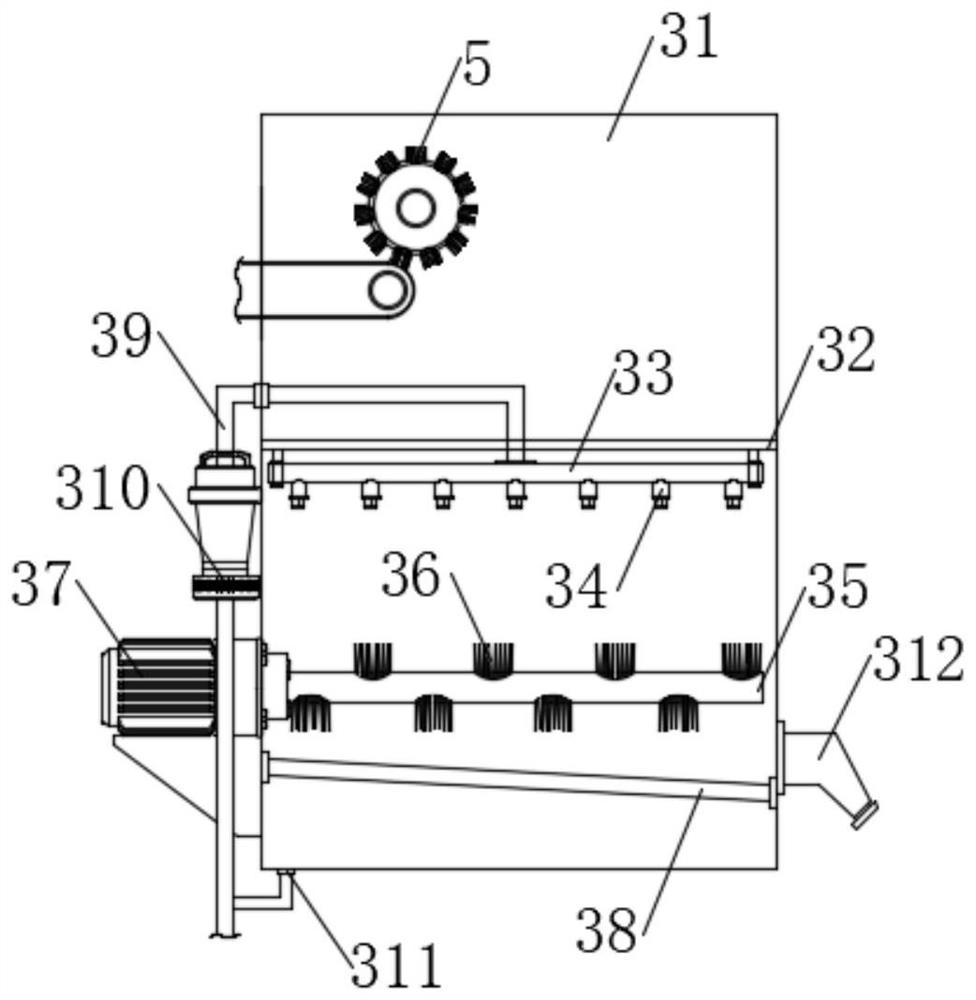

[0023] Such as Figure 1-6 As shown, the present embodiment adopts the following technical solutions: a process for recovering rubber granules using a recovery device for rubber granules, which is characterized in that: it includes the following steps: the first step: the condensed water produced in the production and processing of rubber It is transported from the liquid inlet 8 to the input end of the collecting and conveying mechanism 2 in the collection tank 1 through the external discharge pipe, and the condensed water carrying rubber particles is collected in the water collecting tank 7 by the water guide groove 6 through the filter mesh hole 25, and the condensed water in the condensed water The rubber particles are retained and collected on the conveyor belt 24 to realize the separation, recovery and collection of the rubber particles in the condensed water;

[0024] Second step: under the conveyance of conveyor belt 24, the collected rubber particles are collected in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com