Full-aluminum alloy material van carriage and manufacturing process

A van truck and manufacturing process technology, which is applied to the upper structure of the truck, vehicle components, upper structure, etc., can solve the problems of weak overall strength of the composite material carriage, affecting the mileage of pure electric trucks, and high maintenance costs of the carriage. Achieve the effects of a wide range of appearance color options, improved stability and safety performance, good corrosion resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, objectives and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments and illustrations.

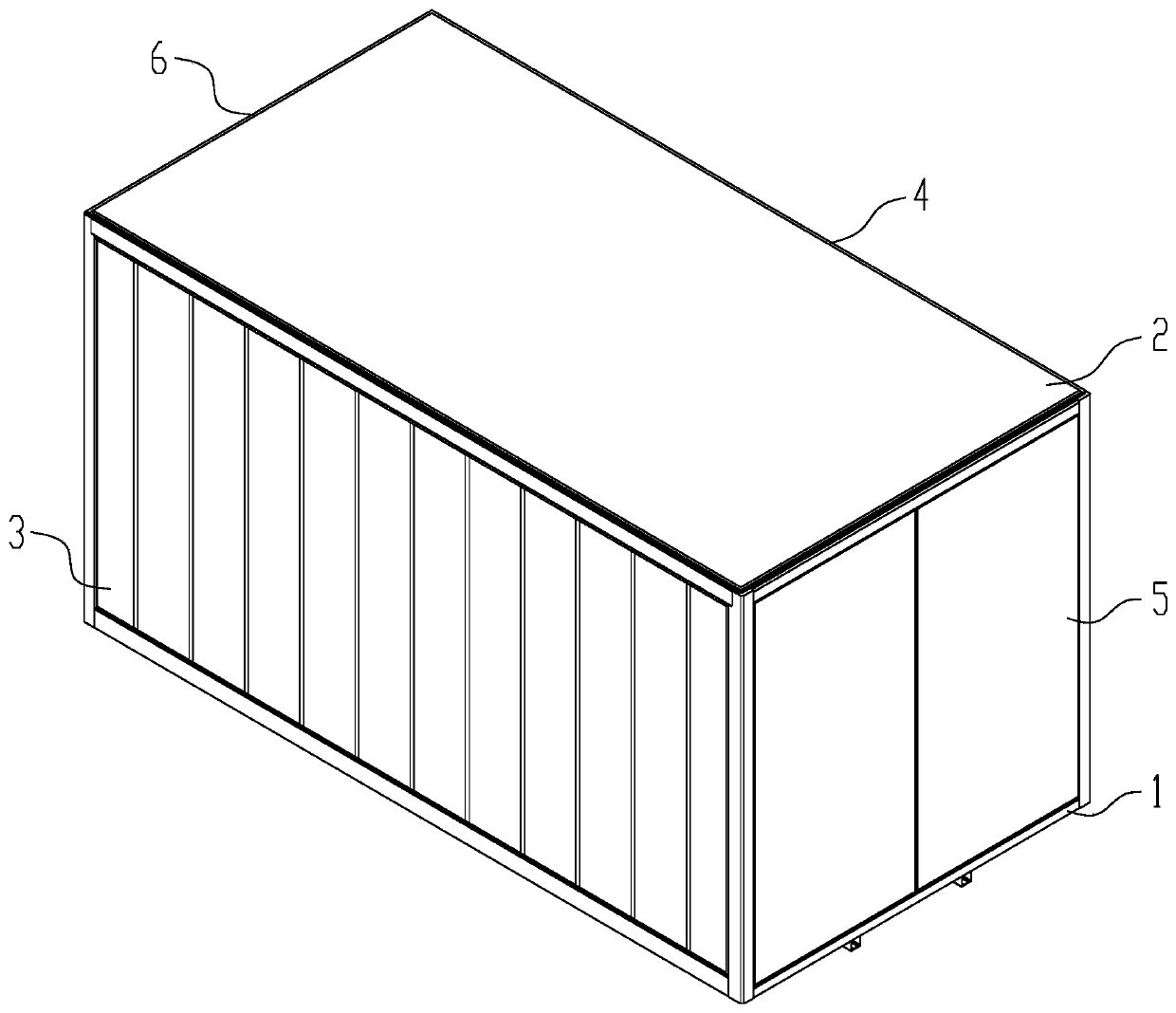

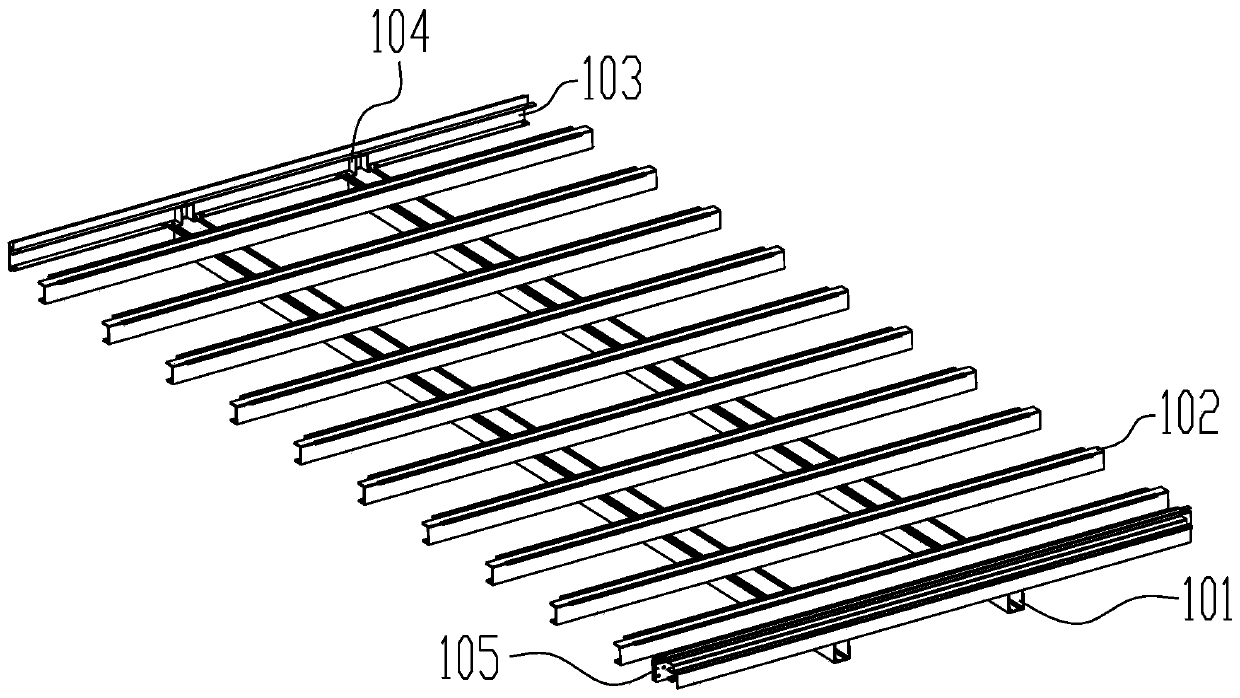

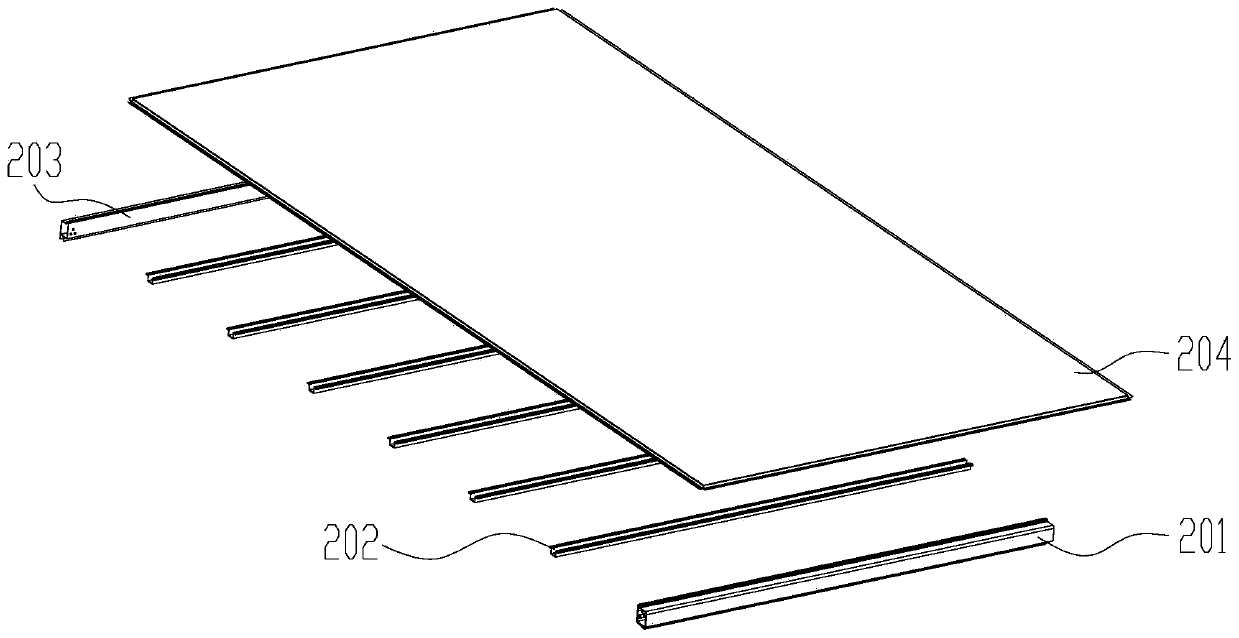

[0028] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 , Figure 7 As shown, the present embodiment is an all-aluminum alloy material van compartment and its manufacturing process, including a floor assembly 1, a roof assembly 2, a left panel assembly 3, a right panel assembly 4, a rear door assembly 5, Front side panel assembly 6. The floor assembly 1 is fixed to the truck chassis girder by two U-shaped bolts, two of the straight beams 101 just fall on the frame girder, and 10 cross beams 102 are arranged in a 90° direction on the two straight beams 101 and It is connected by bolts with the straight beam 101. The front end of the straight beam 101 supports the front side beam 103 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com