Closed self-heating container

A self-heating, closed technology, applied in food heating containers, containers, packaged food, etc., can solve the problems of large hydrogen exhaust, heat loss, heat waste, etc., achieve a stable heating process, reduce hydrogen emissions, reduce Effect of Complaint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

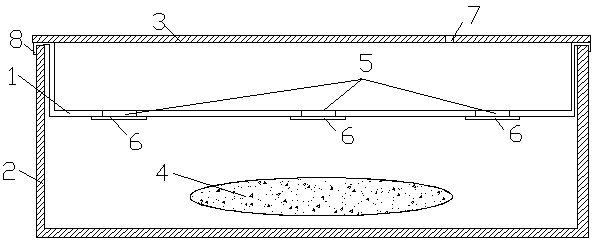

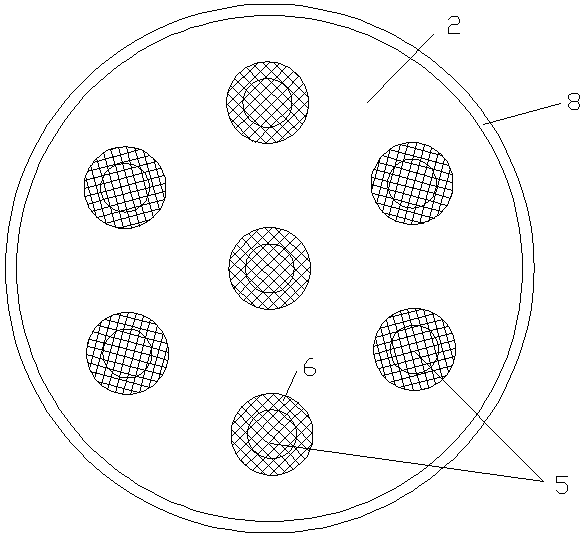

[0023] see figure 1 , 2 , 4;

[0024] A closed self-heating container, which includes a self-heating body 2, the middle part of the self-heating body 2 is airtightly connected with a body to be heated 1, and the top of the self-heating body 2 is a cover body 3;

[0025] A heating hole 5 is opened under the body 1 to be heated, and a polyester filament non-woven fabric 6 is pasted on the heating hole 5 , and a self-heating bag 4 is placed under the self-heating body 2 .

[0026] Further, the polyester filament non-woven fabric 6 has a double-layer structure, its surface layer is a PET polyester layer 61 , and the bottom layer is an SMS melt-blown high-efficiency cloth layer 62 .

[0027] Further, the edge seal between the body to be heated 1 and the self-heating body 2 is a buckle structure 8 .

[0028] Further, the heating holes 5 below the body to be heated 1 are evenly distributed on the bottom of the body to be heated 1 .

[0029] Further, an air outlet 7 is provided on...

Embodiment 2

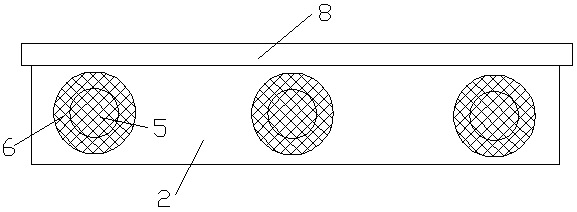

[0032] see image 3 ; On the basis of Example 1, a heating hole 5 is also opened on the side of the body to be heated 1, and the polyester filament non-woven fabric 6 is pasted on the heating hole 5, so that the heating effect is better.

[0033] During use, the water is heated to a chemical reaction in the heating bag 4 to generate heat, and enters the liquid food to be heated (such as a hot pot) in the body to be heated 1 through the heating hole 5 of the polyester filament non-woven fabric 6, and then discharged gas,

[0034] This solution improves the heating efficiency, reduces the weight and hydrogen of the self-heating package, reduces the cost, and the filtered pure steam directly heats the food in a safe and hygienic manner. The use of heat energy reaches the extreme, the steam starts softly, the heating process is stable, and the emission of hydrogen vapor from the steam is reduced. The dust-proof and waterfall-proof solution solves the safety problem of food heatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com