A thick round pipe handling equipment for construction

A technology for handling equipment and construction, applied in the field of handling large-scale thick round pipes, can solve the problems of large space occupied by cranes, inconvenient operation, low work efficiency, etc., and achieve the effects of low production cost, convenient operation and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

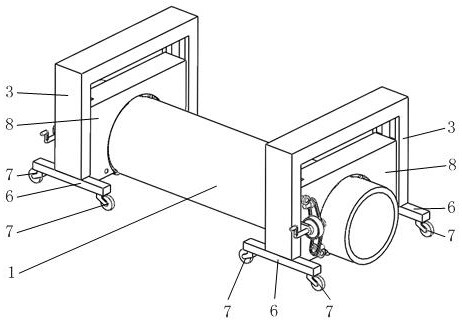

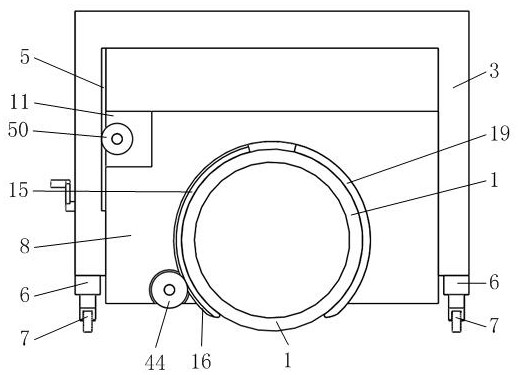

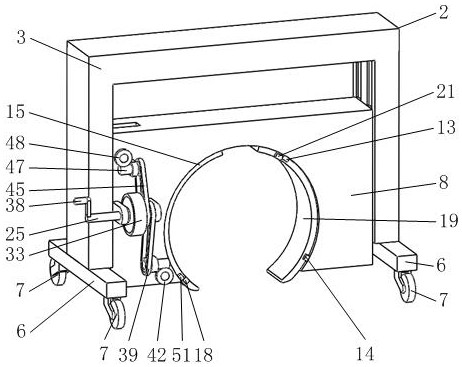

[0035] The accompanying drawings are all schematic diagrams of the implementation of the present invention, so as to understand the principle of structural operation. The specific product structure and proportional size can be determined according to the use environment and conventional technology.

[0036] Such as image 3 , 4 , 5, it includes door frame A3, door frame B8, holding plate A15, holding plate B19, rotating shaft A25, gear A26, bushing A27, bushing B28, disc A29, gear B31, gear barrel 33, worm A41 , worm gear A42, gear C44, worm B47, worm gear B48, gear D50, such as figure 2 , 3 As shown, the door frame B8 slides vertically in the door frame A3, and there is a moving device on the door frame A3; the arc-shaped holding plate A15 and the arc-shaped holding plate B19 respectively slide on the arc of the door frame B8 around their respective arc center axes. on the inner wall of the shape; Figure 4 , 13 As shown in , 15, there is a position-limiting structure ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com