a maa -co- daa -co- pegma copolymer and its preparation method and application

A technology of maa-co-daa-co-pegma and copolymer, applied in the field of MAA-co-DAA-co-PEGMA copolymer and its preparation, can solve the problem of low drug loading, no targeting ability and slow drug release and other problems, to achieve the effects of high degradability, high drug loading, and wide application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A MAA-co-DAA-co-PEGMA copolymer, the preparation process is as follows:

[0028] .

[0029] The preparation steps are:

[0030] (1) Dissolve 0.27 g TBDMS-DAA in 2 mL DMF to obtain a TBDMS-DAA solution; dissolve 0.085 g BACy in 1 mL DMF to obtain a BACy solution; dissolve 2 mmol TBAF in 10 mL THF to obtain 0.2 mol / LTBAF solution;

[0031] (2) Under nitrogen atmosphere, add 0.492 g MAA, 0.198 g PEGMA (average molecular weight 300), 0.0692 g SDS, and the TBDMS-DAA solution and BACy solution obtained in step (1) into 36 mL of water, mix, and heat to 80 °C with stirring , added 0.001 g APS, reacted for 8 h, washed by centrifugation, and freeze-dried at -40 °C;

[0032] (3) The product obtained in step (2) was added to 10 mL of TBAF solution, stirred, centrifuged to collect the precipitate, washed with THF, washed with water, and freeze-dried at -45 °C to obtain MAA-co-DAA-co-PEGMA copolymer.

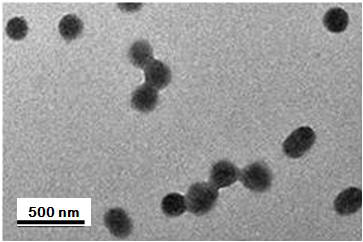

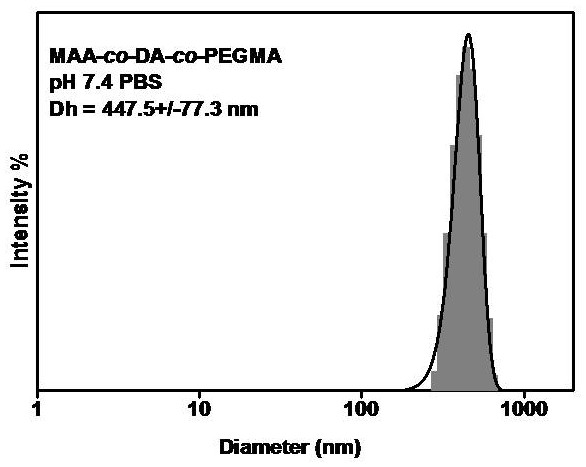

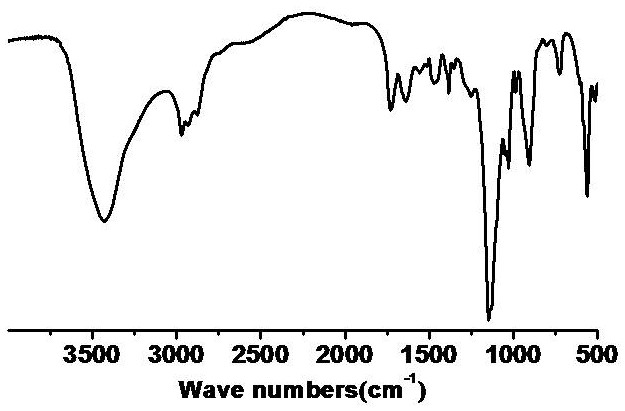

[0033] figure 1 TEM image of MAA-co-DAA-co-PEGMA copolymer. Depend on fi...

Embodiment 2

[0038] The difference with Example 1 is: in step (2), the consumption of TBDMS-DAA is kept unchanged, and the consumption of MAA is adjusted according to the MAA:TBDMS-DAA molar equivalent ratio of 32:2, and the others are the same as in Example 1.

Embodiment 3

[0040] The difference with Example 1 is: in step (2), the consumption of TBDMS-DAA is kept constant, the MAA:TBDMS-DAA molar equivalent ratio is 8:2 to adjust the consumption of MAA, and the others are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com