A method for in-situ growth of defective cuprous sulfide nanoparticles on carbon nitride nanosheets

A cuprous sulfide and nanoparticle technology, applied in the field of photocatalysis, can solve the problems of restriction, high price, waste, etc., and achieve the effects of strong operability, mild reaction conditions, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation of blank carbon nitride

[0035] Take a certain amount of dicyandiamide and place it in a porcelain ark, cover it, and put it in a muffle furnace for calcination. The temperature was raised to 550°C at a rate of 3°C / min, and kept at this temperature for 4 hours. After it was naturally cooled to room temperature, it was ground, washed and dried to obtain CN.

Embodiment 2

[0037] Accurately weigh 2g of dicyandiamide (C 2 h 4 N 4) In a mortar, add 10 g of ammonium chloride (NH 4 Cl), fully grind to mix the two evenly, then transfer the ground medicine to a porcelain boat and put it into a muffle furnace for calcination, heat up to 550°C at a rate of 3°C / min, and keep at this temperature for 4h. After the calcination process, it was naturally cooled to room temperature, and the porcelain ark was taken out to obtain a light yellow carbon nitride nanosheet sample. The sample was fully ground and stored for later use. The obtained sample was marked as CNNs.

Embodiment 3-5

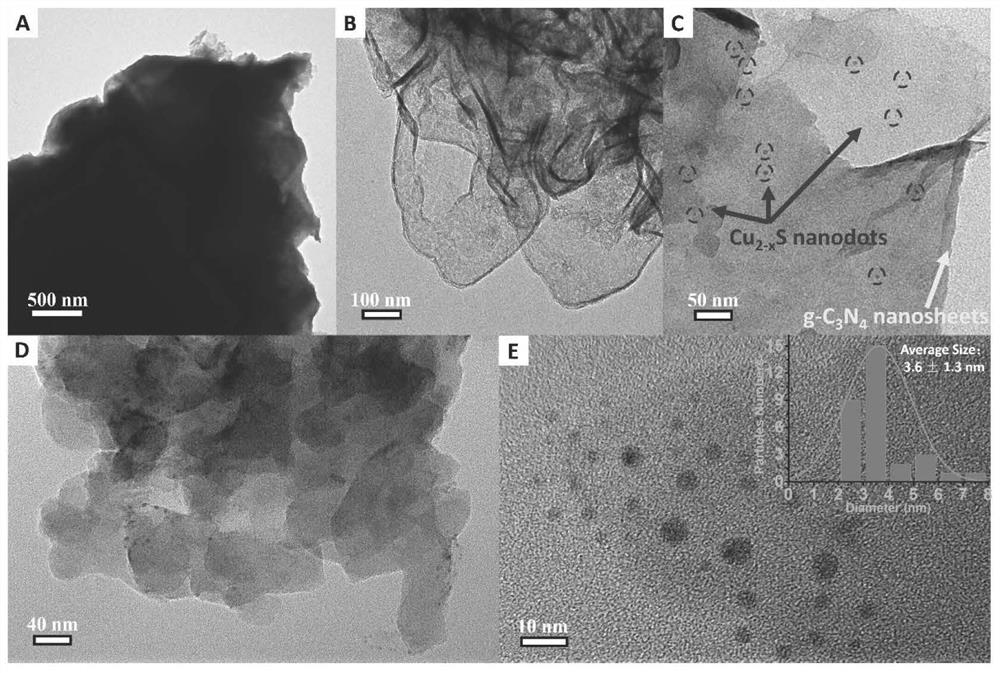

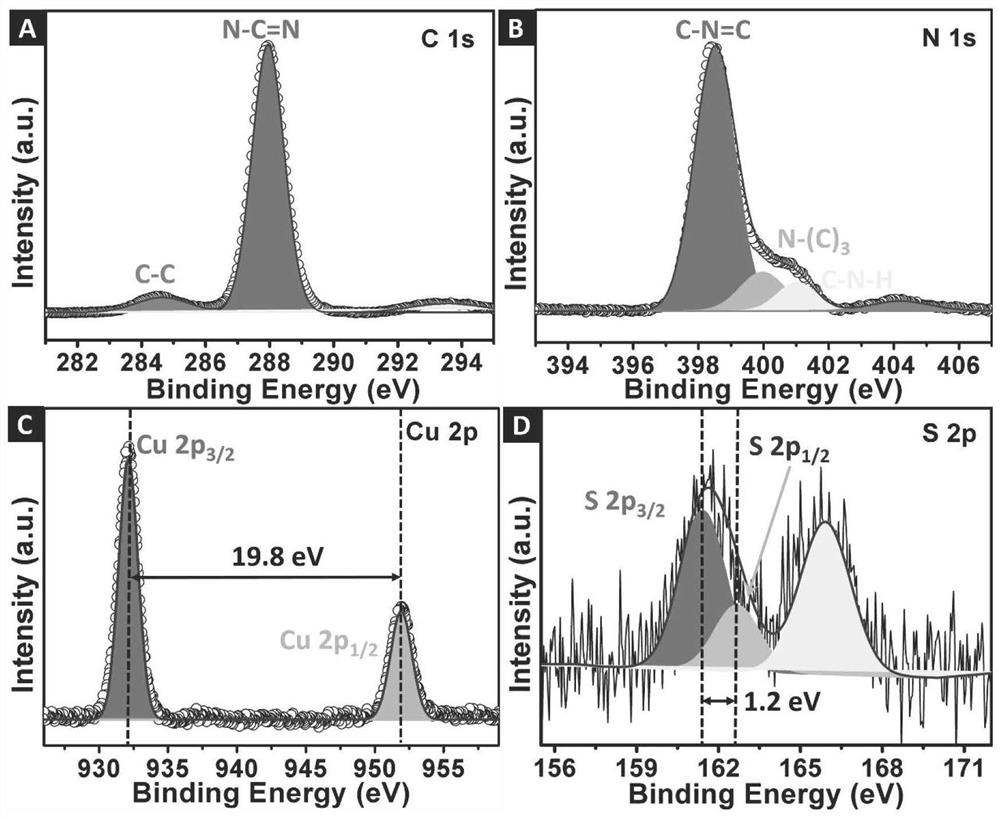

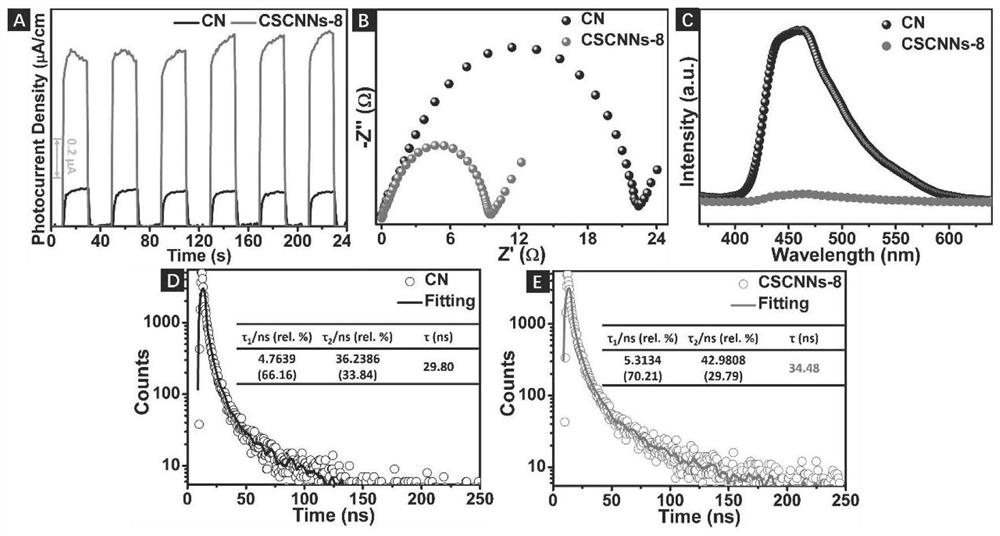

[0039]Disperse 64mg of sulfur powder in 12ml of oleylamine dispersion, marked as A; disperse 100mg of copper acetylacetonate in 20ml of chloroform dispersion, marked as B; accurately weigh 1g of carbon nitride nanosheets prepared in Example 2 (CNNs) was dispersed into a mixed solution of 20ml chloroform and 18ml oleylamine, marked as C, and the solution C was transferred to a 50mL round bottom flask and placed in an oil bath, slowly heated and stirred in a 70°C oil bath for 20min, Then add 120 μL, 480 μL, and 960 μL of solution A, and stir for 20 minutes, then add 1 mL, 4 mL, and 8 mL of solution B in turn, and stir for 40 minutes. After cooling down to room temperature naturally, the solution was taken out, washed several times with deionized water, and dried to obtain photocatalyst samples. The three samples were theoretically grown in situ with mass fractions of 0.2%, 0.8%, and 1.6% Cu 2-x Cu of S nanoparticles 2-x For S / CNNs composites, the three samples are labeled CSCNN...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com