Tm<3+>/Yb<3+> double-doped alpha-NaYF4 monocrystal for solar spectrum modulating and preparation method thereof

A solar spectrum, double-doping technology, applied in the field of Tm3+/Yb3+ double-doped α-NaYF4 single crystal and its preparation, can solve the problems of poor stability and performance of glass materials, achieve good thermal properties, facilitate large-scale industrial production, and improve quality Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

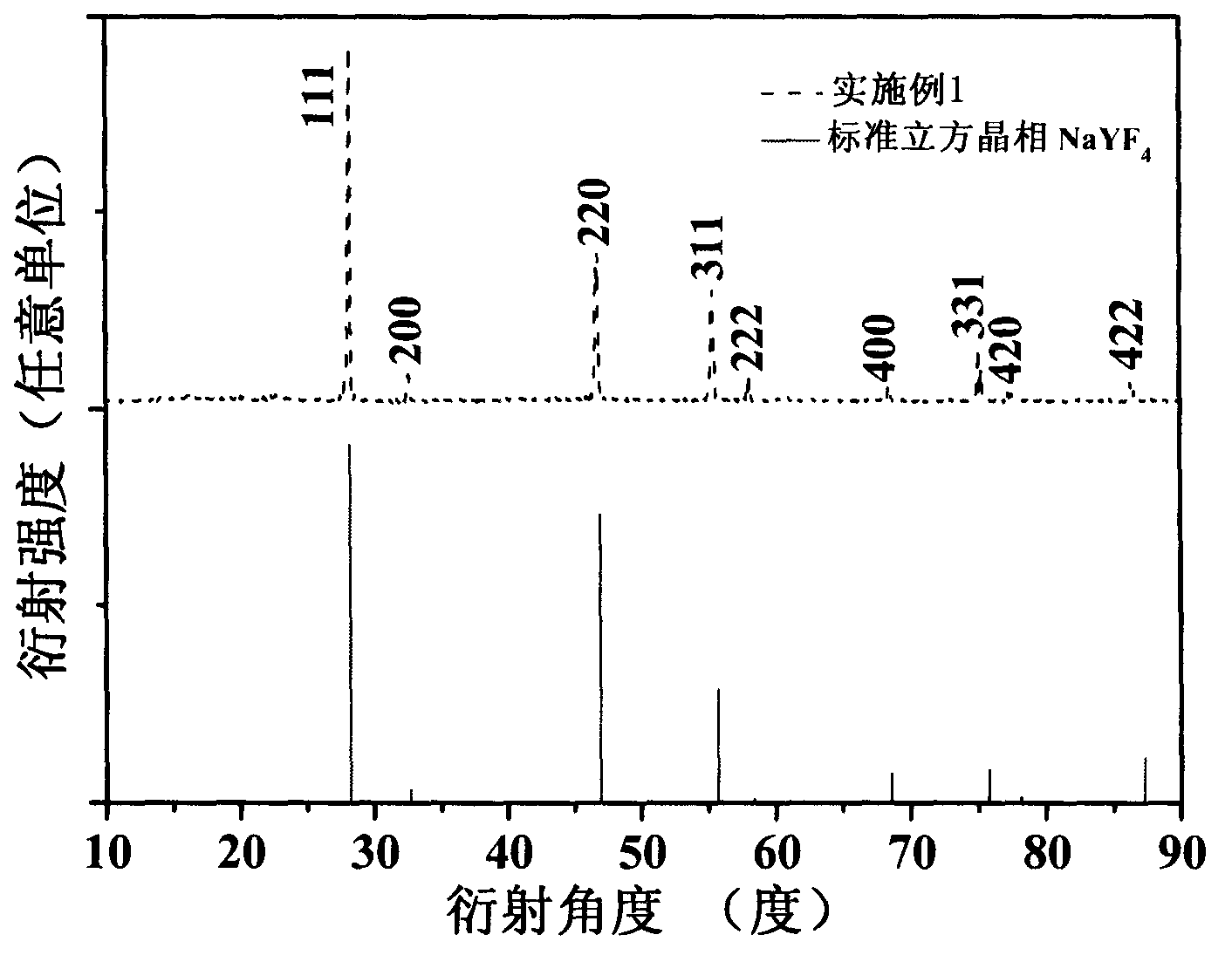

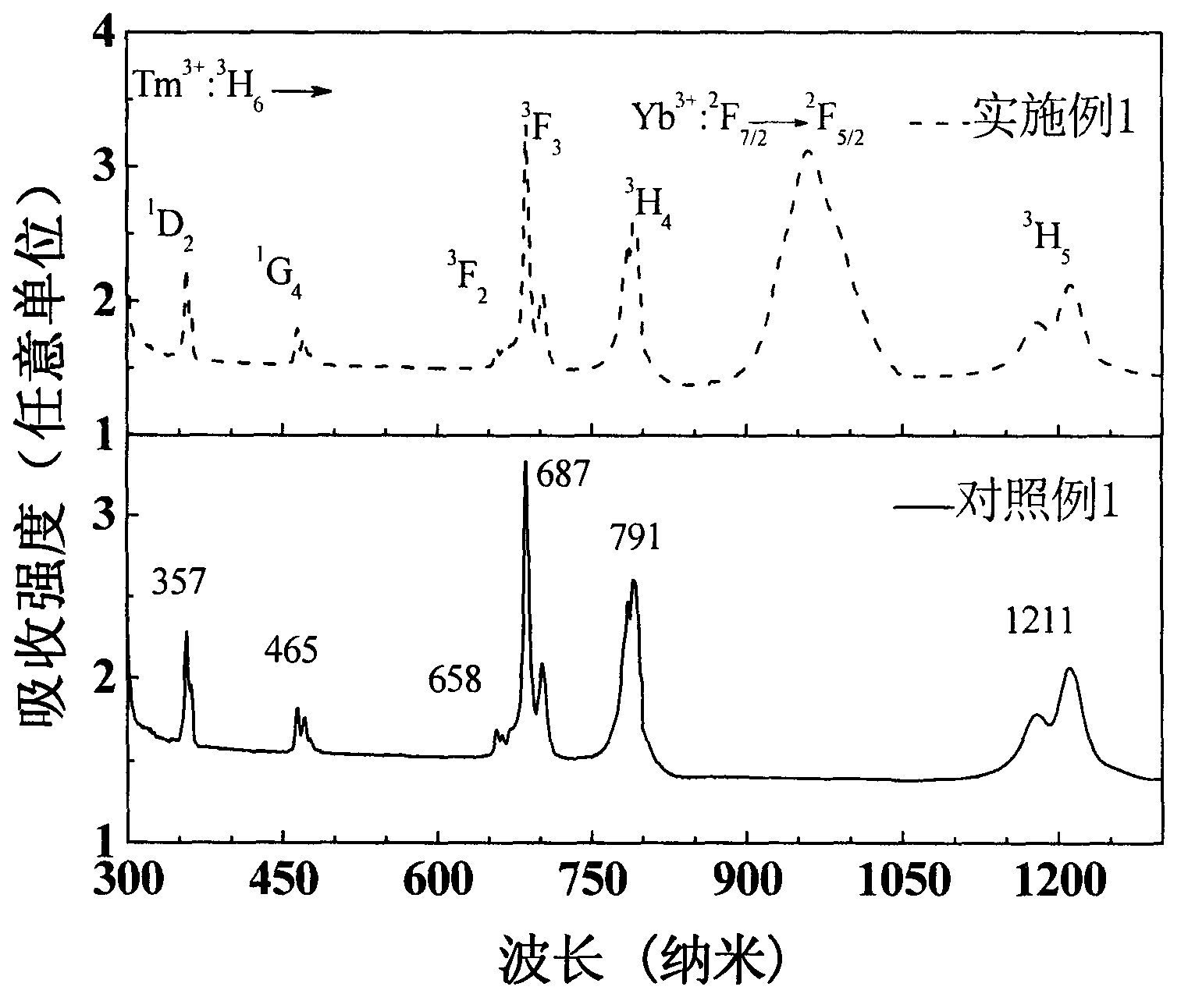

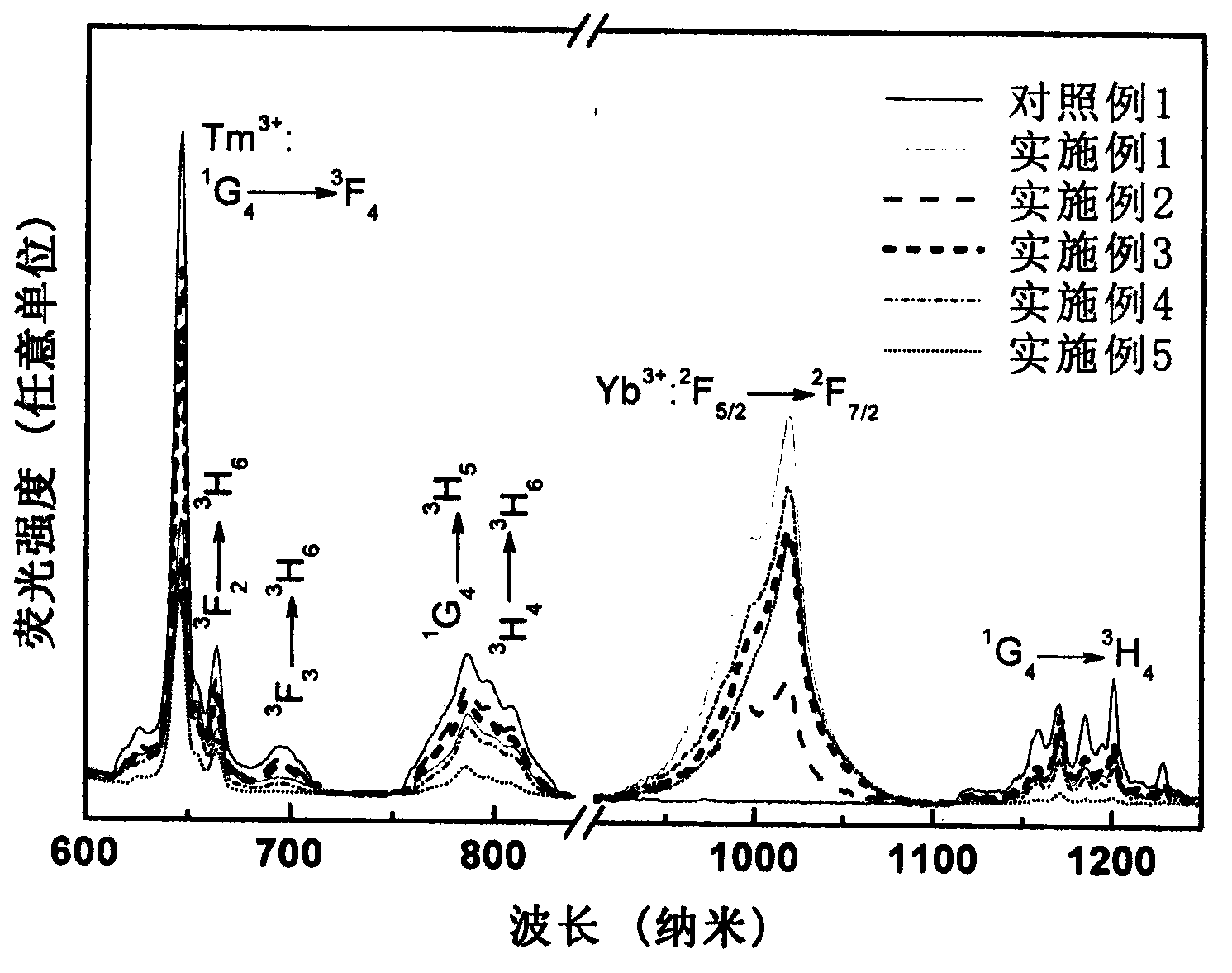

Embodiment 1

[0024] Weigh NaF, KF, YF with purity greater than 99.99% 3 , TmF 3 , YbF 3 Raw material, molar ratio NaF:KF:(YF 3 +TmF 3 +YbF 3 )=1.6:1:2.8, and TmF 3 : YbF 3 =1:12, YF 3 :(TmF 3 +YbF 3 )=1: 0.0695, place the raw materials in a mill, grind and mix for 5.5 hours to obtain a mixture of uniform powder; put the mixture in a boat-shaped platinum crucible, and then install the boat-shaped platinum crucible in a tube type resistance furnace in the platinum tube, and then use high-purity N 2 The gas removes the air in the platinum pipeline, and the platinum pipeline is leaked; then the furnace body temperature of the tubular resistance furnace is gradually increased to 790 ° C, HF gas is passed through, and the reaction is carried out for 2 hours to remove the H that may be contained. 2 O and oxyfluoride, in the reaction process, use NaOH solution to absorb HF gas in the exhaust gas. After the reaction is over, stop the HF gas flow, close the tube resistance furnace, and fin...

Embodiment 2

[0029] Basically the same as Example 1, the only difference is the molar ratio NaF:KF:(YF 3 +TmF 3 +YbF 3 ) = 1.6:1:2.8, and TmF 3 : YbF 3 =1:4, YF 3 :(TmF 3 +YbF 3 )=1:0.0256, the raw materials were placed in the mill, and the mixture was milled and mixed for 5 hours to obtain a uniform powder mixture; the raw materials were mixed and placed in the mill, and then the furnace body temperature of the tubular resistance furnace was gradually increased When the temperature reaches 800 °C, HF gas is passed through, the reaction time is 2 hours, the furnace temperature is 970 °C, the inoculation temperature is 840 °C, the temperature gradient of the solid-liquid interface is 80 °C / cm, the crystal growth rate is 0.2 mm / h, and the furnace temperature is lowered to the temperature. At 80°C / h, transparent crystals were obtained. Determination of Tm in Crystals by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP) 3+ , Yb 3+ The actual molar content of rare earth ion...

Embodiment 3

[0031] Basically the same as Example 1, the only difference is the molar ratio NaF:KF:(YF 3 +TmF 3 +YbF 3 ) = 1.6:1:2.8, and TmF 3 : YbF 3 =1:8, YF 3 :(TmF 3 +YbF 3 )=1:0.0989, the raw materials were placed in the mill, and the mixture was milled and mixed for 5 hours to obtain a uniform powder mixture; the raw materials were mixed and placed in the mill, and then the furnace body temperature of the tubular resistance furnace was gradually increased to 770°C, pass HF gas, the reaction time is 5 hours, the furnace temperature is 950°C, the inoculation temperature is 820°C, the temperature gradient of the solid-liquid interface is 60°C / cm, the crystal growth rate is 0.6mm / h, and the furnace temperature drop temperature is 20°C / h to obtain transparent crystals. Determination of Tm in Crystals by Inductively Coupled Plasma Atomic Emission Spectroscopy (ICP) 3+ , Yb 3+ The actual molar content of rare earth ions, x=0.0049, y=0.0398, and the crystal chemical formula is α-Na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com