A kind of fiber material with impact resistance and preparation method thereof

A technology of impact resistance and fiber material, which is applied in the field of fiberboard with impact resistance and its preparation, can solve the problems that impact resistance affects design and application, threatens the service life of materials and structures, and is easily attacked by heavy objects. The effect of easy realization, simple preparation method and excellent impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

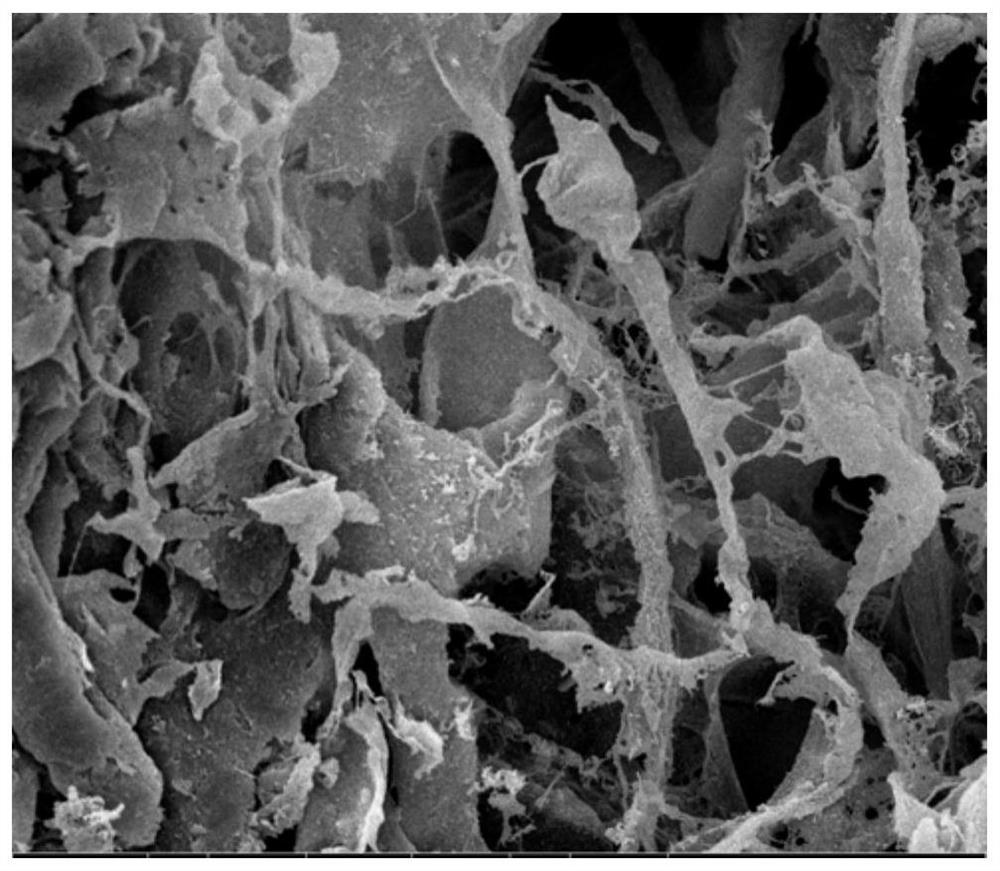

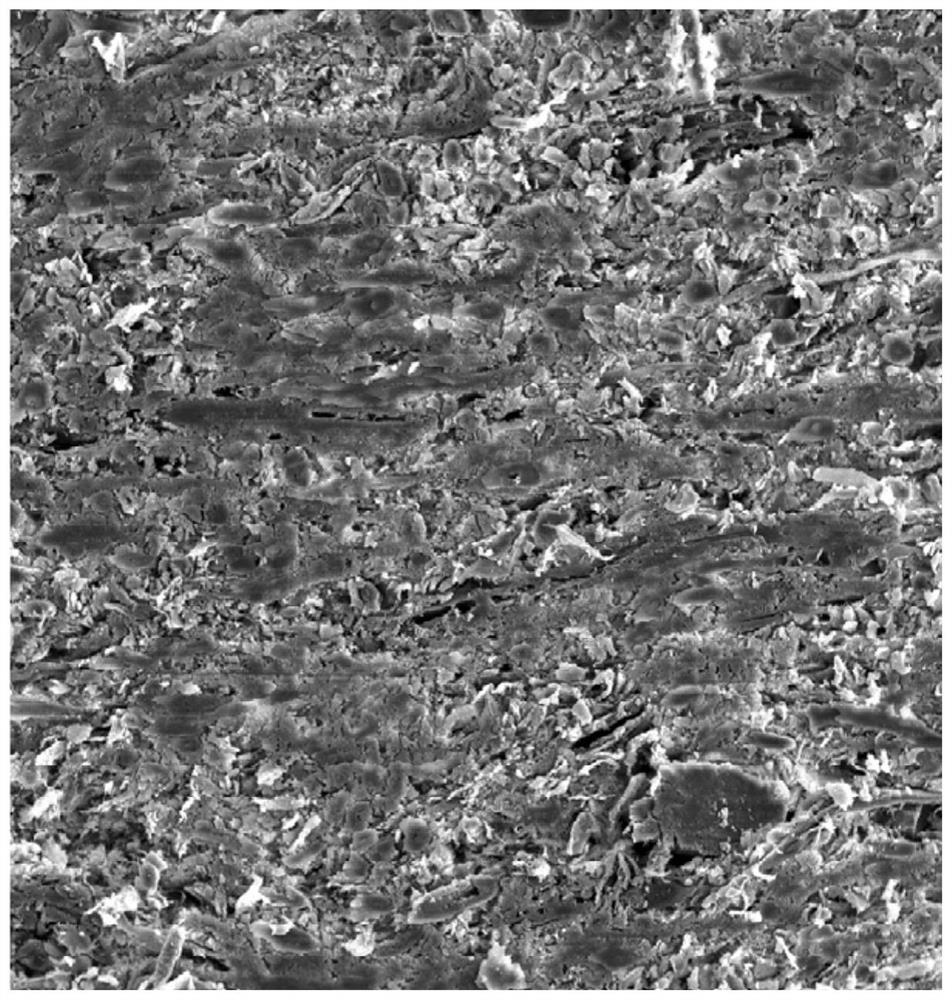

[0033] A method for preparing a fiber material with impact resistance, comprising the following steps:

[0034] S1: Pulverize the biomass fiber, and then mix with NaOH, Na 2 SO 3 Dissolved in distilled water to form a suspension, the biomass fiber: NaOH: Na 2 SO 3 : The mass ratio of distilled water is 20:60:40:2000; S2: Send the suspension obtained in S1 into a colloid mill for grinding to obtain a grinding liquid, wherein the colloid mill speed is 2500rpm, and the grinding time is 10h; S3 : Pour the grinding solution obtained in S2 into a Buchner funnel and carry out suction filtration for 10 hours to obtain the precursor of the impact-resistant fiber material; S4: impregnate the impact-resistant polymer material PBDMS into the precursor of the impact-resistant fiber material obtained in S3, and then carry out The finished product is obtained by hot pressing, the impact-resistant polymer material in the finished product is 1% by mass, the hot pressing time is 0.5h, the te...

Embodiment 2

[0036] A method for preparing a fiber material with impact resistance, comprising the following steps:

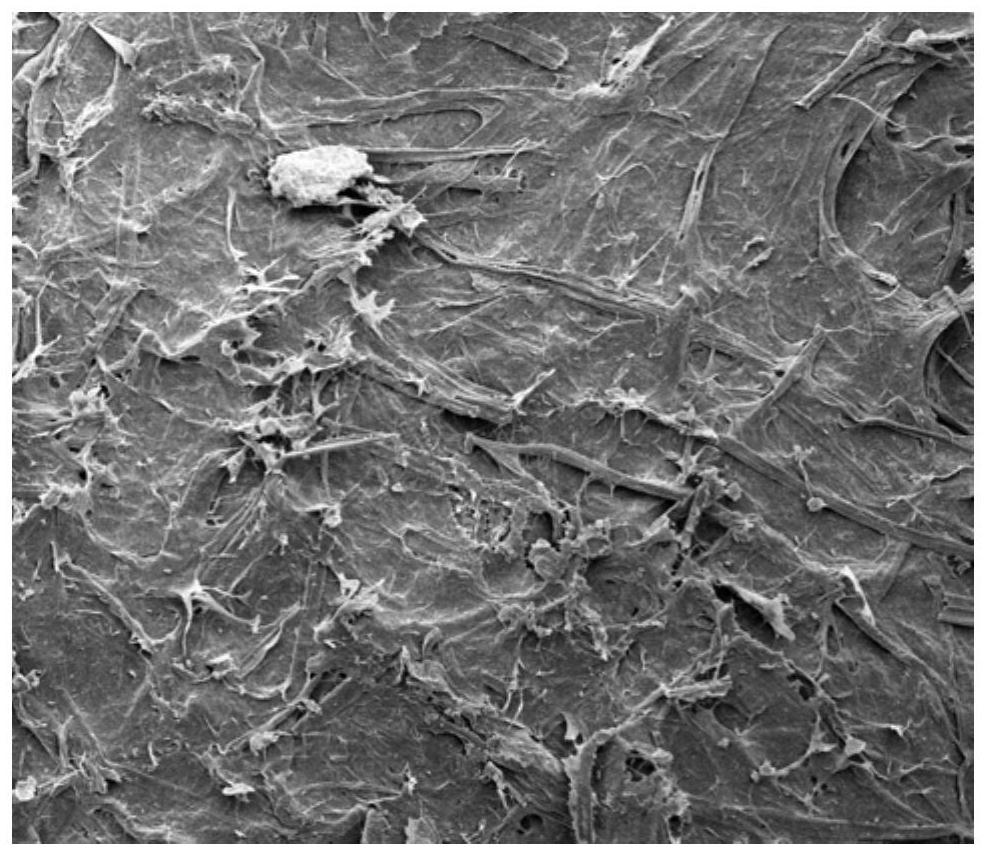

[0037] S1: Pulverize the biomass fiber, and then mix with NaOH, Na 2 SO 3 Dissolved in distilled water to form a suspension, the biomass fiber: NaOH: Na 2 SO 3 : The mass ratio of distilled water is 40:120:80:2000; S2: Send the suspension obtained in S1 into a colloid mill for grinding to obtain a grinding liquid, wherein the speed of the colloid mill is 3000rpm, and the grinding time is 5h; S3 : Pour the grinding solution obtained in S2 into a Buchner funnel for suction filtration for 15 hours to obtain the impact-resistant fiber material precursor; S4: impregnate the impact-resistant polymer material PBDMS into the impact-resistant fiber material precursor obtained in S3, and then carry out The finished product is obtained by hot pressing. The mass percentage of the impact-resistant polymer material in the finished product is 10%. The hot pressing time is 2 hours, the ...

Embodiment 3

[0039] A method for preparing a fiber material with impact resistance, comprising the following steps:

[0040] S1: Pulverize the biomass fiber, and then mix with NaOH, Na 2 SO 3 Dissolved in distilled water to form a suspension, the biomass fiber: NaOH: Na 2 SO 3: The mass ratio of distilled water is 30:100:50:2000; S2: Send the suspension obtained in S1 into a colloid mill for grinding to obtain a grinding liquid, wherein the speed of the colloid mill is 2880rpm, and the grinding time is 6h; S3 : Pour the grinding liquid obtained in S2 into a Buchner funnel and carry out suction filtration for 12 hours to obtain the precursor of the impact-resistant fiber material; S4: impregnate the impact-resistant polymer material PBDMS into the precursor of the impact-resistant fiber material obtained in S3, and then carry out The finished product is obtained by hot pressing. The mass percentage of the impact-resistant polymer material in the finished product is 5%, the hot pressing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com