Natural-wax-luster coloring treatment agent and preparation method thereof

A wax light touch and treatment agent technology is applied in the field of natural wax light touch treatment agent and the preparation of natural wax light touch treatment agent. Light perception and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

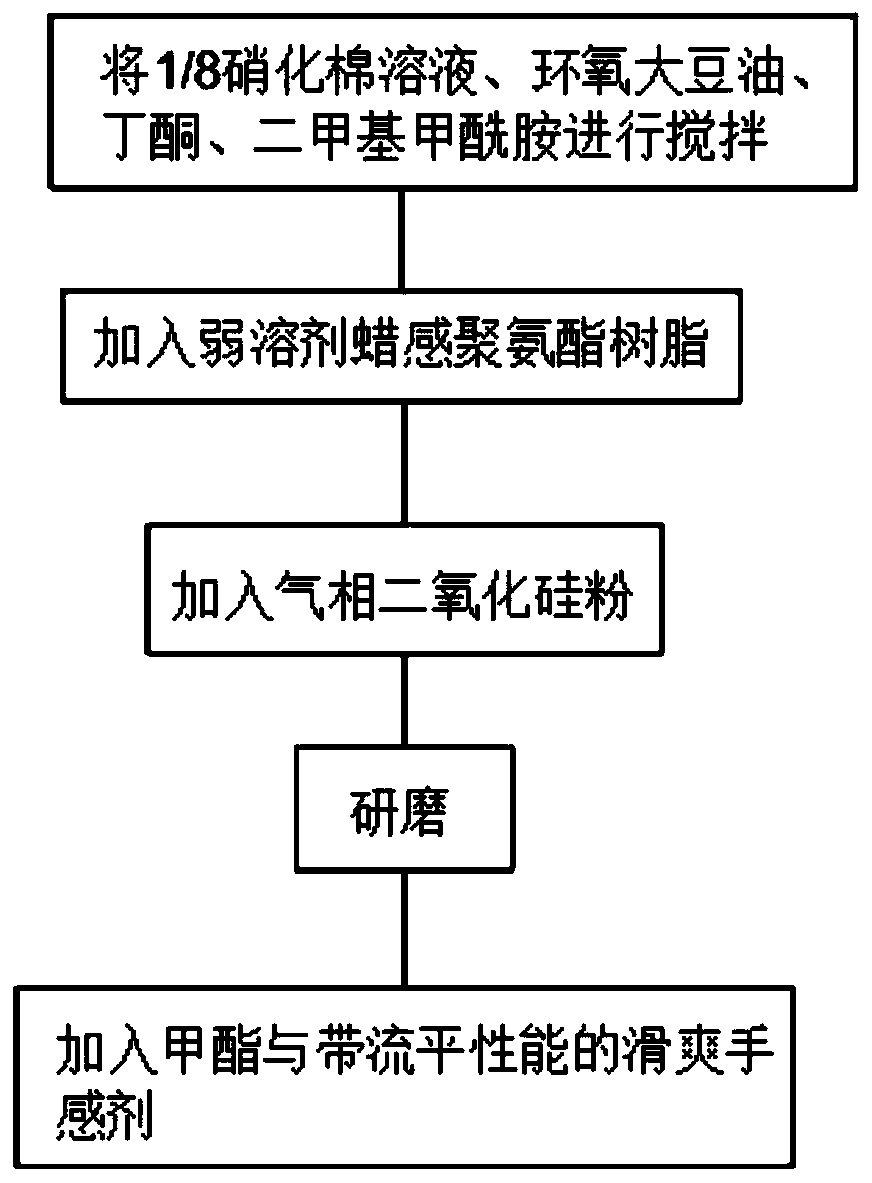

[0028] see figure 1 , the present invention provides a kind of technical proposal: a kind of natural glazing treatment agent, is made of the raw material of following parts by weight: 1 / 8 nitrocellulose solution 25g, epoxidized soybean oil 2.7g, butanone 10g, dimethyl 5g of formamide, 15g of weak solvent waxy polyurethane resin, 1.2g of fumed silica powder, 14g of methyl ester and 0.2g of slippery feel agent with leveling properties.

[0029] A preparation method of a natural waxy touch color treatment agent, comprising the following steps:

[0030] S1: Add 25g of 1 / 8 nitrocellulose solution, 2.7g of epoxidized soybean oil, 10g of methyl ethyl ketone, and 5g of dimethylformamide into the tank for stirring, at room temperature for 20 minutes, the stirring process is carried out with a stirrer, and the stirrer is kept at 1000-1500 rpm;

[0031] S2: Add 15g of weak solvent waxy polyurethane resin and stir;

[0032] S3: Add 1.2g of fumed silica powder, and continue to stir unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com