Mask plate frame

A mask plate and frame technology, which is applied in the field of OLED preparation, can solve problems such as opening position deviation, evaporation position deviation, and affecting display effects, and achieve the effects of preventing deformation, ensuring product quality, and reducing the number of scrapped

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

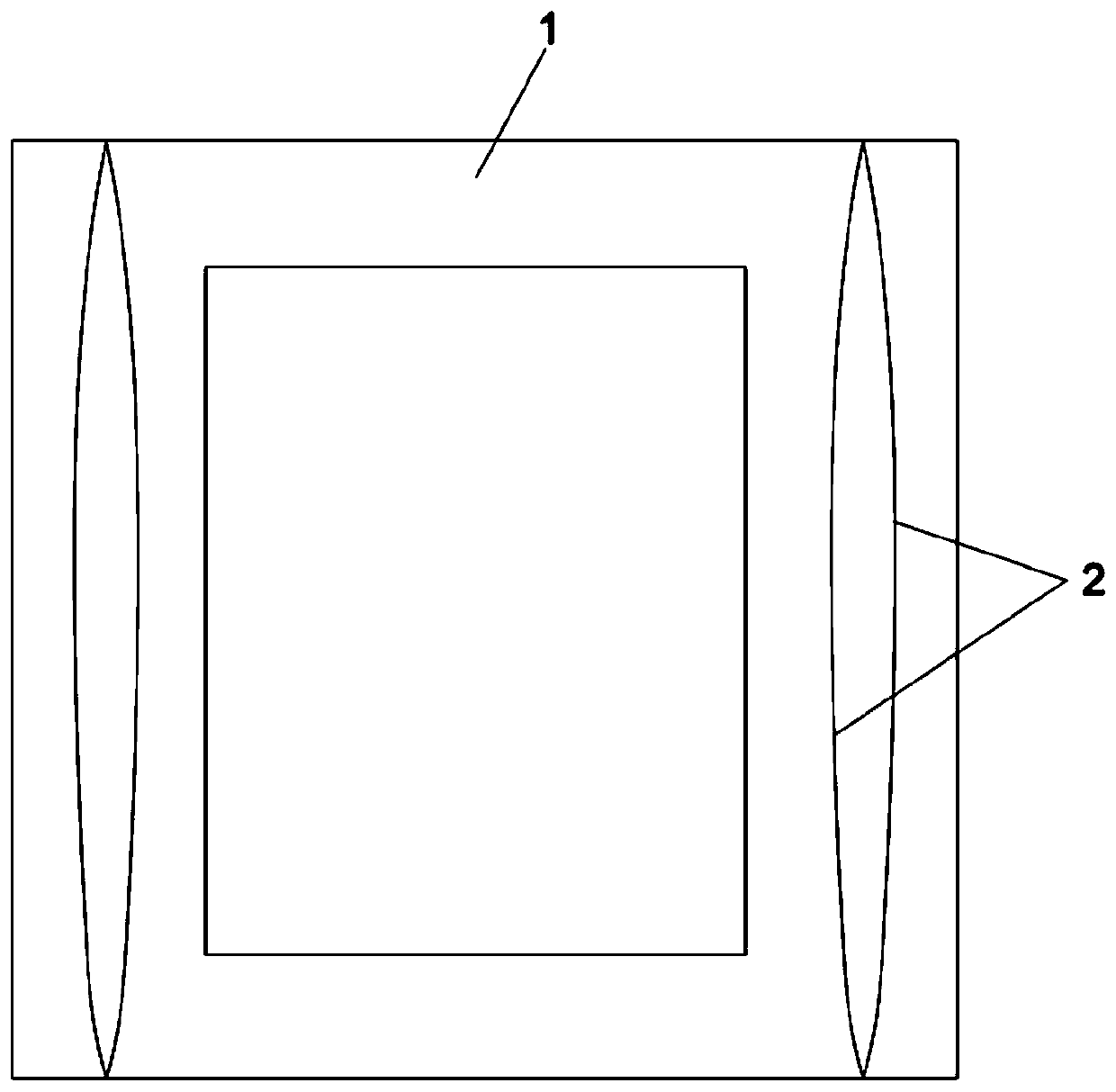

[0030] This embodiment discloses a mask frame, such as figure 1 As shown, it includes a frame body 1. The frame body 1 includes a plurality of frames connected end to end. The frame is provided with an arc-shaped rectification structure. The rectification structure extends along the length direction of the frame where it is located. The rectification structure is configured to be The frame body 1 provides prestressed deformation to correct the deformation of the mask.

[0031] In this embodiment, the frame body 1 is a square frame structure, including four frames connected end to end. Specifically, the mask frame provided by this embodiment can be applied to the situation where the full-page mask has been seriously shrunk or expanded. Such as figure 1 As shown, the rectification structure includes a pair of arc-shaped grooves 2 with opposite bending directions and prestressed ribs embedded in the arc-shaped grooves 2, and the arc-shaped grooves 2 extend along the length dire...

Embodiment 2

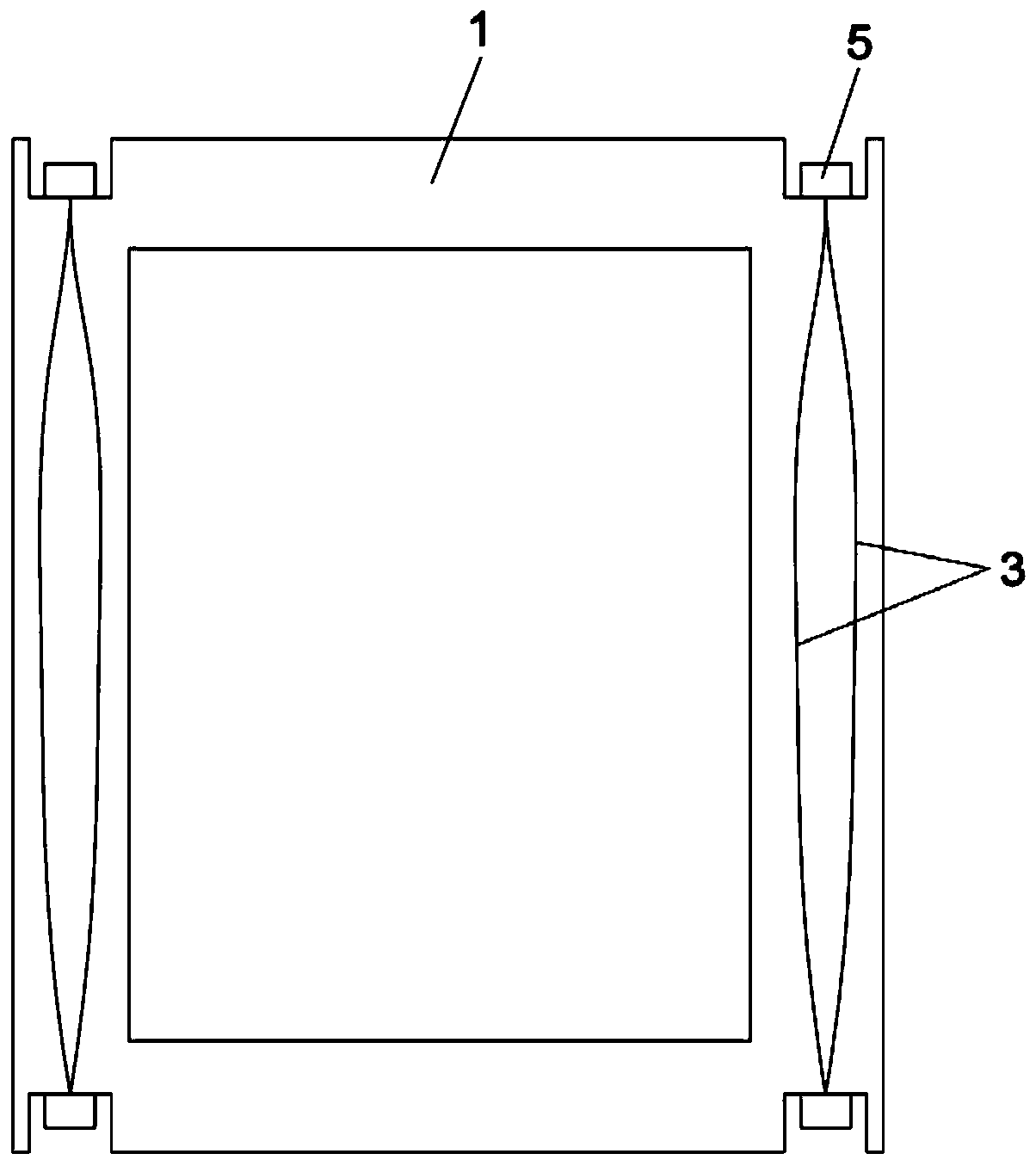

[0044] This embodiment provides a mask frame. The difference between the mask frame structure and the mask frame structure in Embodiment 1 is that the specific structure of the correction structure is different.

[0045] The mask plate frame provided in this embodiment is suitable for the production process of the mask plate frame before vacuum evaporation production. The mask plate frame can be adjusted in the subsequent vacuum evaporation process to prevent deformation of the mask plate, so as to improve the accuracy of pixel positions, thereby ensuring product quality.

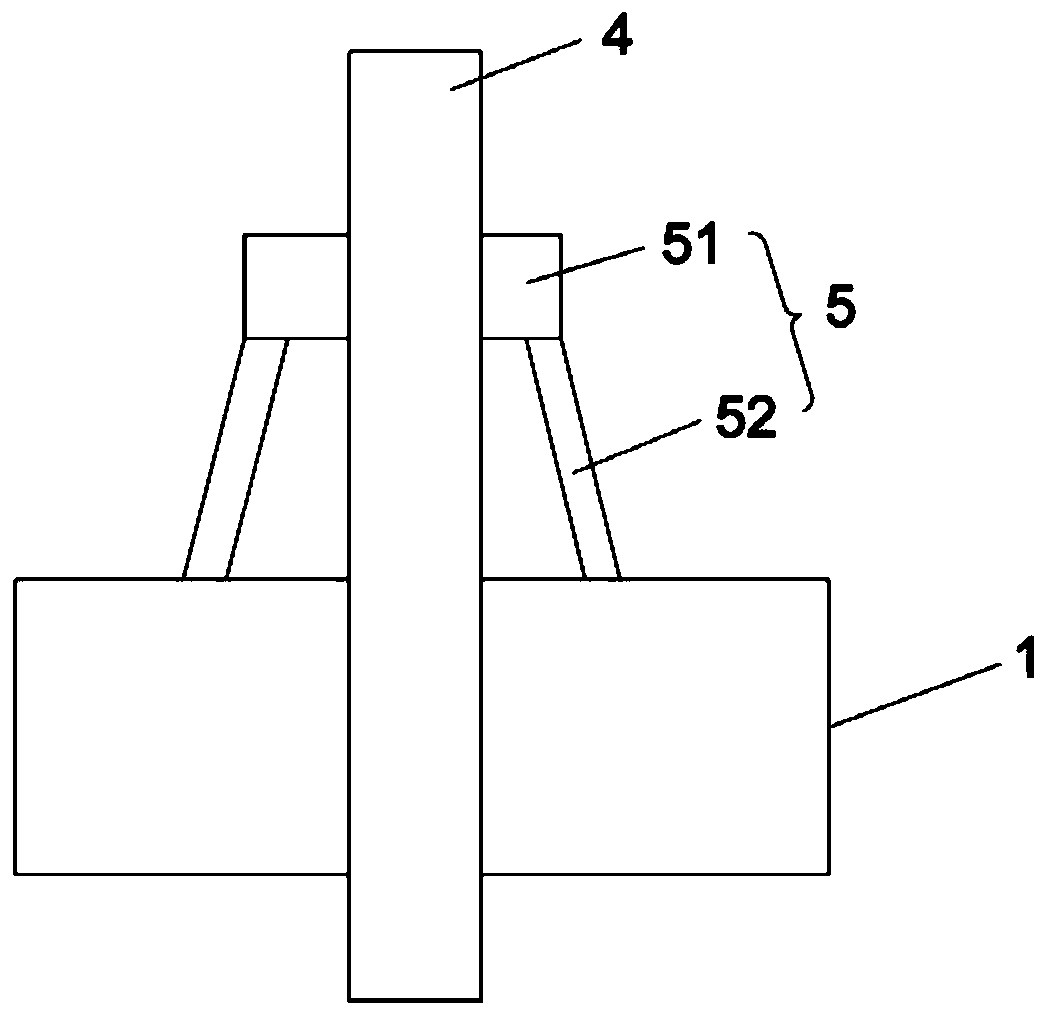

[0046] Specifically, as figure 2 and image 3 As shown, the correction structure on the mask frame includes a pair of arc-shaped tunnels 3 with opposite bending directions, a correction steel bar 4 arranged in the arc-shaped tunnel 3, and an adjustment member 5 connected to both ends of the correction steel bar 4. The shaped hole 3 extends through the length direction of the frame where it is located, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com