Water turbine rotating wheel main shaft flange with corrosion-resistance friction structure

A shaft flange and water turbine technology, which is applied in couplings, hydroelectric power generation, mechanical equipment, etc., can solve the high stability requirements of the joint surface of the water turbine runner and the main shaft, which affects the stability of the joint surface of the water turbine runner and the main shaft, Erosion affects stability, reliability, service life and other issues, and achieves the effect of reducing the possibility of water flow entering the flange sealing sleeve, increasing connection stability, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

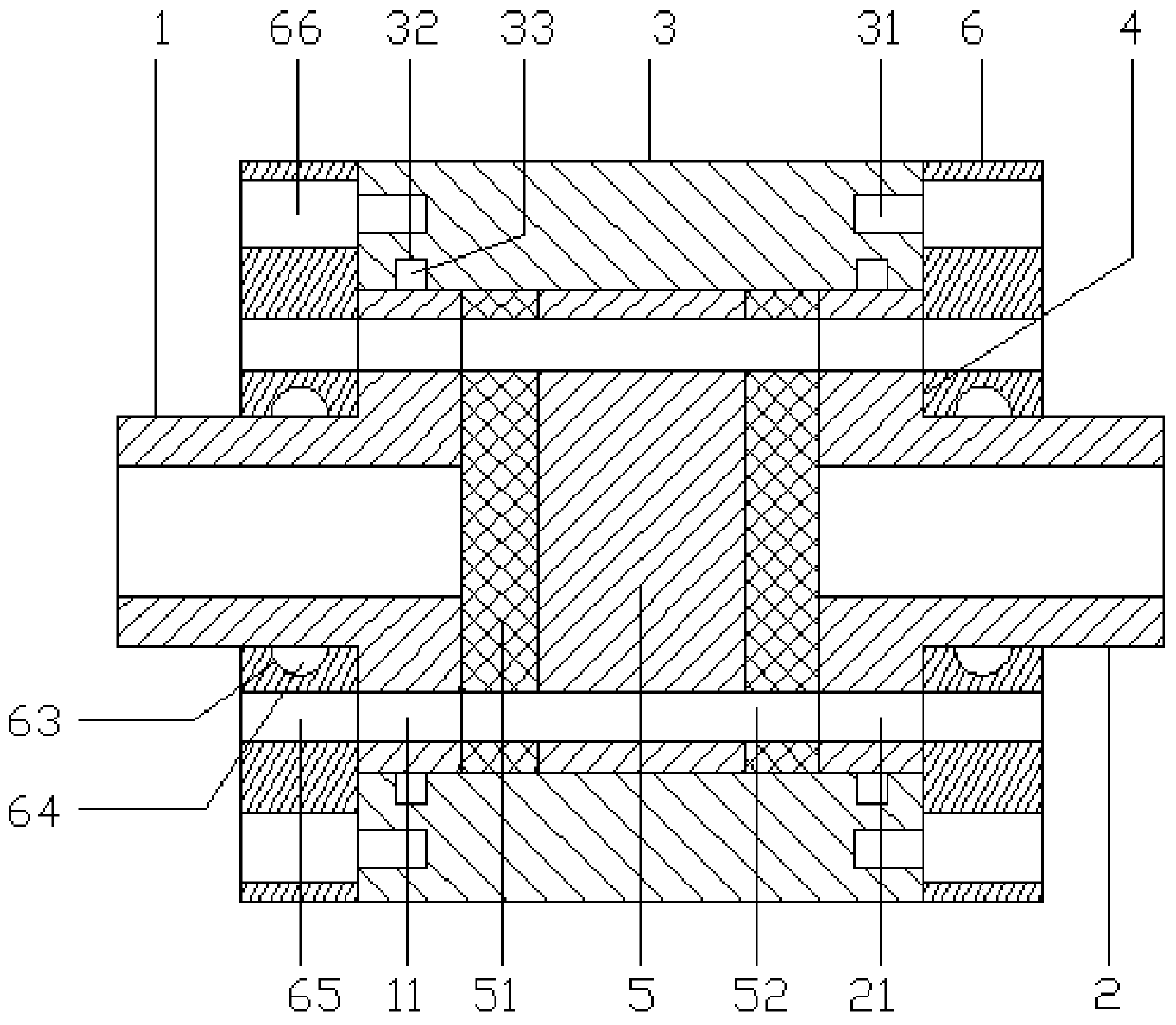

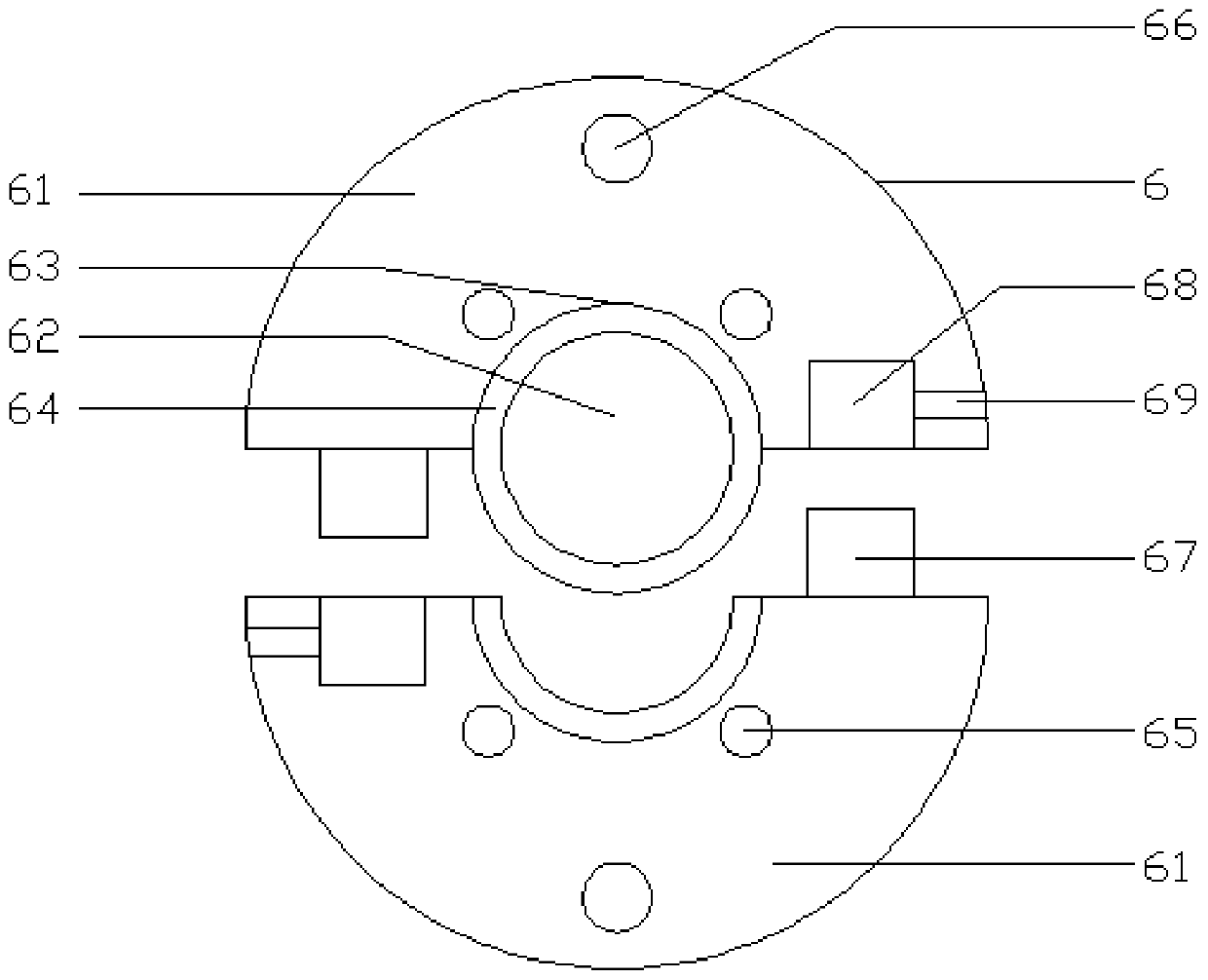

[0017] Referring to the accompanying drawings, the invention shows a water turbine runner main shaft flange with anti-corrosion friction structure, including main shaft flange 1, shaft flange 2, flange sealing sleeve 3, flange installation groove 4, anti-corrosion friction module 5 and flange A sheet fastening mechanism 6, a shaft flange 2 is provided on the right side of the main shaft flange 1, a flange sealing sleeve 3 is provided between the main shaft flange 1 and the shaft flange 2, and the flange sealing sleeve 3 There is a flange installation groove 4 inside, the flange connection piece of the main shaft flange 1 and the shaft flange 2 is located inside the flange installation groove 4, the flange connection piece of the main shaft flange 1 and the rotation shaft flange 2 An anti-corrosion friction module 5 is arranged between the main shaft flange 1 and the rotating shaft flange 2. A flange fastening mechanism 6 is provided on the outside of the main shaft flange 1 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com