Melting device for adhesive of carbon contact strip of pantograph

A pantograph carbon slide and melting device technology, which is applied to mixers with rotating stirring devices, current collectors, electric vehicles, etc., can solve the problems of easy shaking of the gelling barrel, low heating efficiency, and inconvenient fixing of the gelling barrel, etc. problem, achieve the effect of improving melting efficiency, simple structure and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

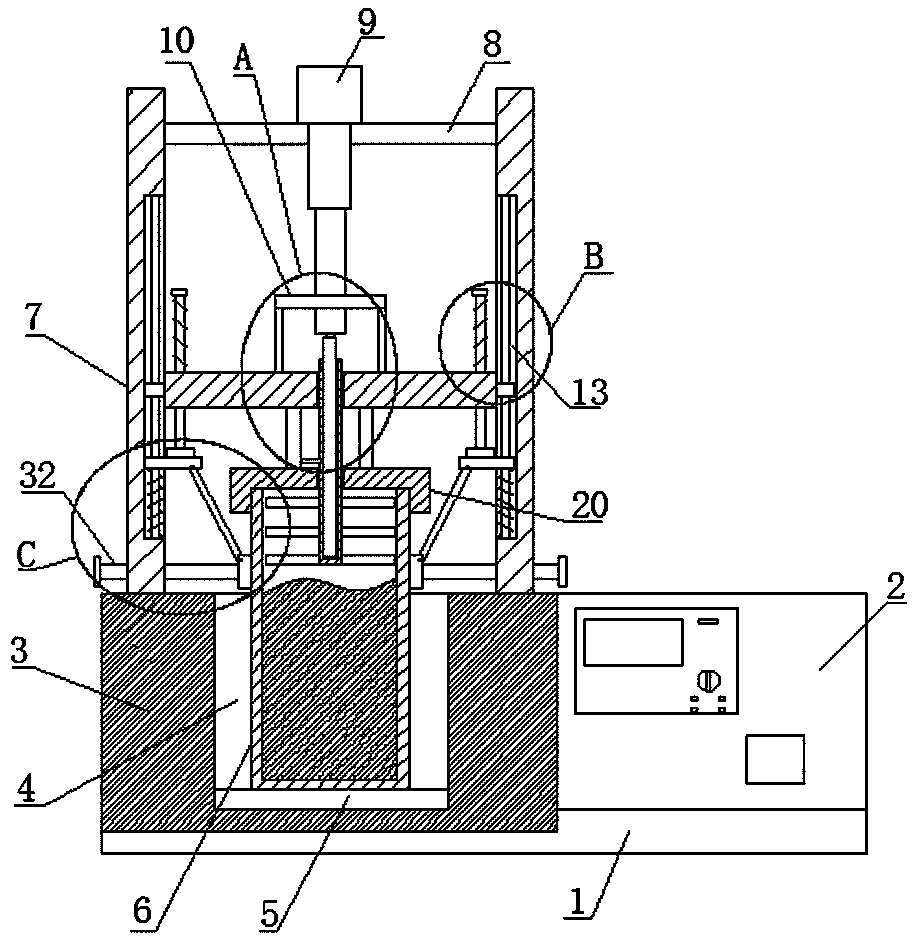

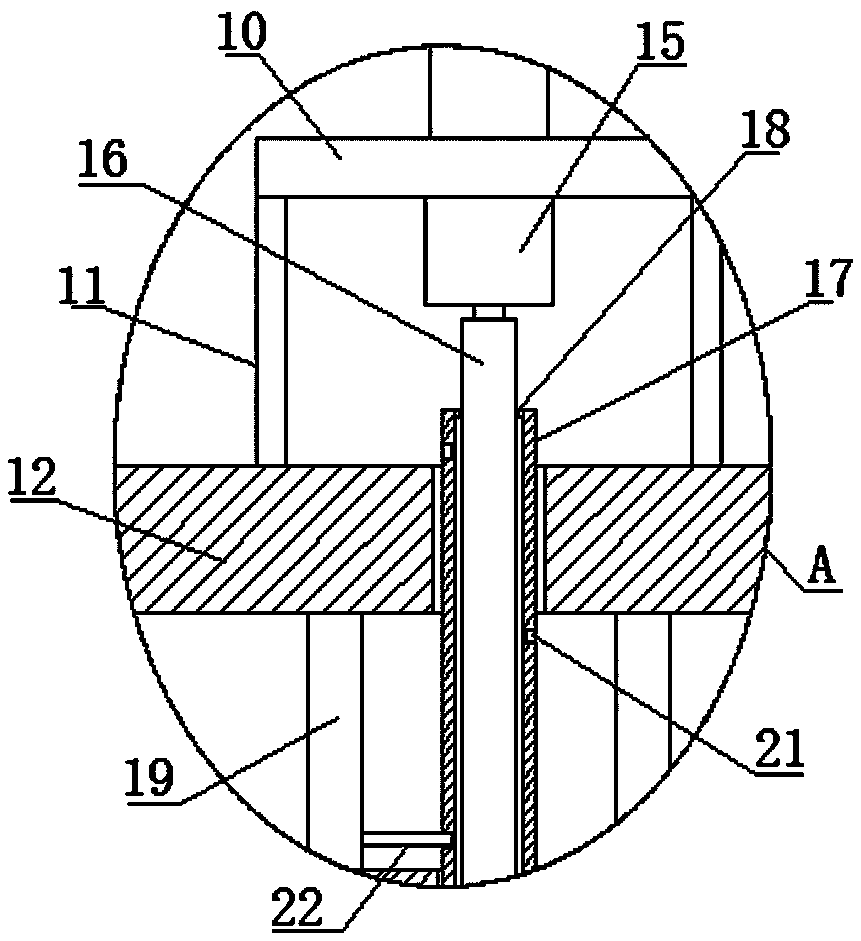

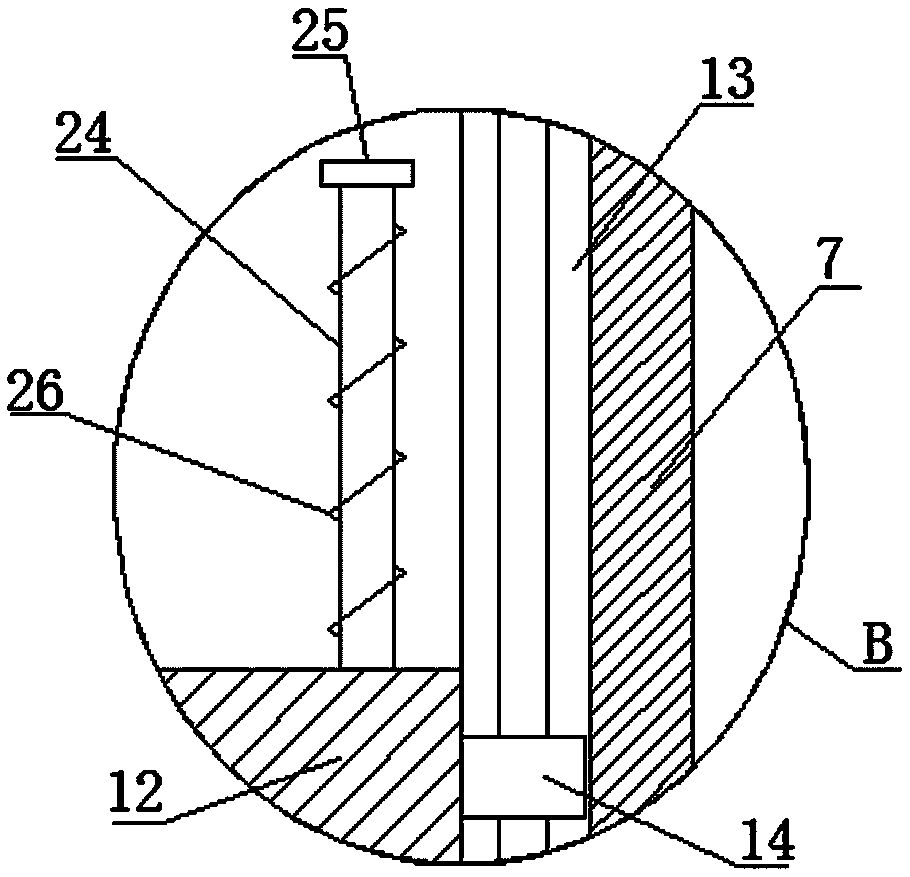

[0030] refer to Figure 1-5 , a pantograph carbon skateboard adhesive melting device, comprising a base 1, the base 1 is provided with a console 2, the console 2 is provided with a temperature controller, the top of the base 1 is provided with a placement seat 3, and the top of the placement seat 3 A heating tank 4 is provided, a gelling barrel 6 is arranged in the heating tank 4, a heating seat 5 is arranged on the inner wall of the bottom of the heating tank 4, and a plurality of heating tubes are arranged in the heating seat 5, and two A support seat 7, the same connecting seat 8 is fixedly installed on the side where the two supporting seats 7 are close to each other, the top of the connecting seat 8 is fixedly installed with a cylinder 9, and the output shaft of the cylinder 9 extends to the bottom of the connecting seat 8 and is fixedly installed There is a push plate 10, and the push plate 10 is located between the two support seats 7. When in use, the gelling barrel 6 ...

Embodiment 2

[0041] refer to Figure 1-5 , a pantograph carbon skateboard adhesive melting device, comprising a base 1, the base 1 is provided with a console 2, the console 2 is provided with a temperature controller, the top of the base 1 is provided with a placement seat 3, and the top of the placement seat 3 A heating tank 4 is provided, a gelling barrel 6 is arranged in the heating tank 4, a heating seat 5 is provided on the inner wall of the bottom of the heating tank 4, and a plurality of heating tubes are arranged in the heating seat 5, and the top of the placing seat 3 is fixed and installed by welding There are two supporting bases 7, and the side of the two supporting bases 7 close to each other is fixedly installed with the same connecting base 8 by welding, and the top of the connecting base 8 is fixedly installed with a cylinder 9 by welding, and the output shaft of the cylinder 9 extends to the connecting base 8 and is fixedly installed with a push plate 10 by welding, the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com