Bullet loading device and large-caliber bullet disassembly equipment

A projectile and feeding technology, which is applied in the direction of offensive equipment, ammunition, transportation and packaging, etc., can solve the problems of high labor intensity, low work efficiency, and many occupied personnel, so as to reduce labor intensity, reduce the number of workers, and improve work safety Coefficient and the effect of production operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions in the embodiments of the present invention are clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only part of the embodiments of the present invention, not all of them. Based on the embodiments of the present invention, all other embodiments obtained by persons of ordinary skill in the art without making creative efforts belong to the protection scope of the present invention.

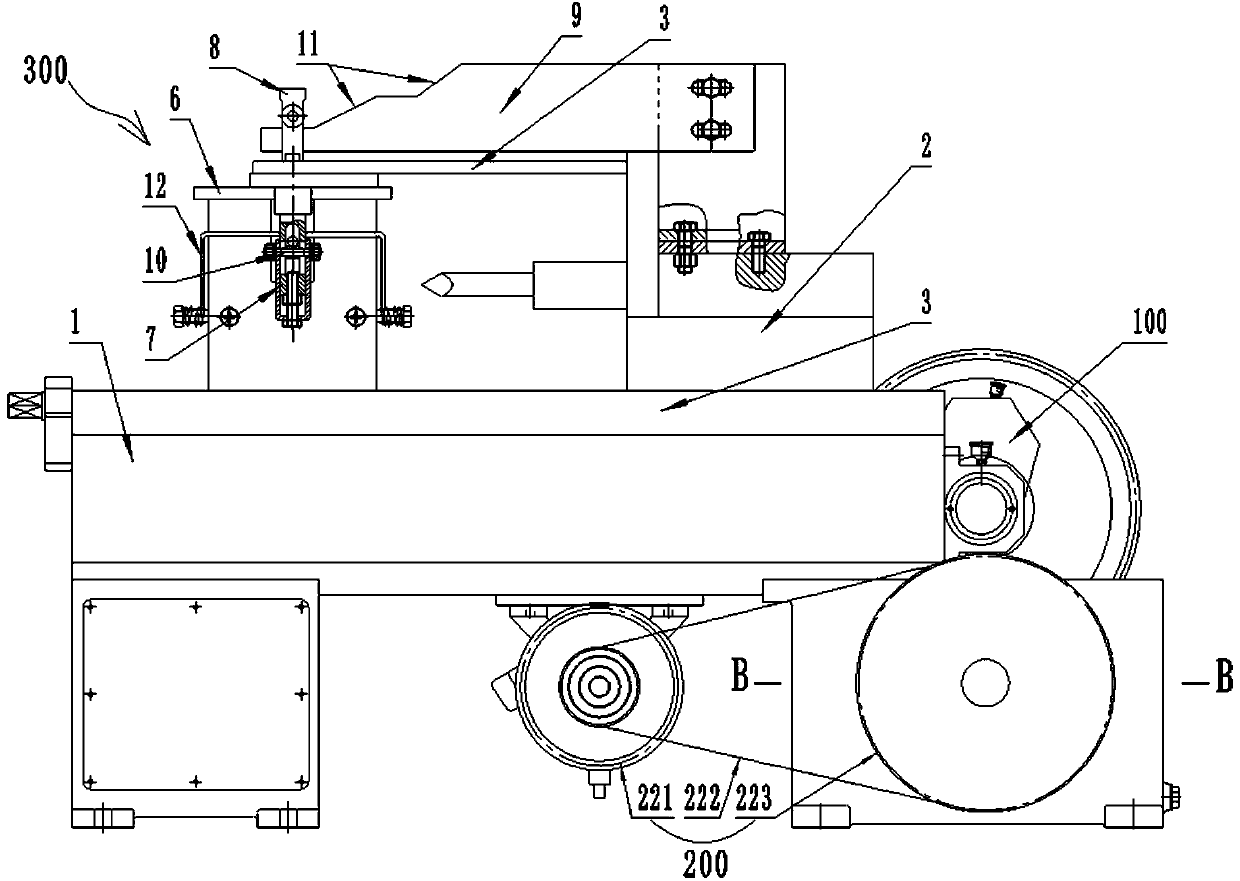

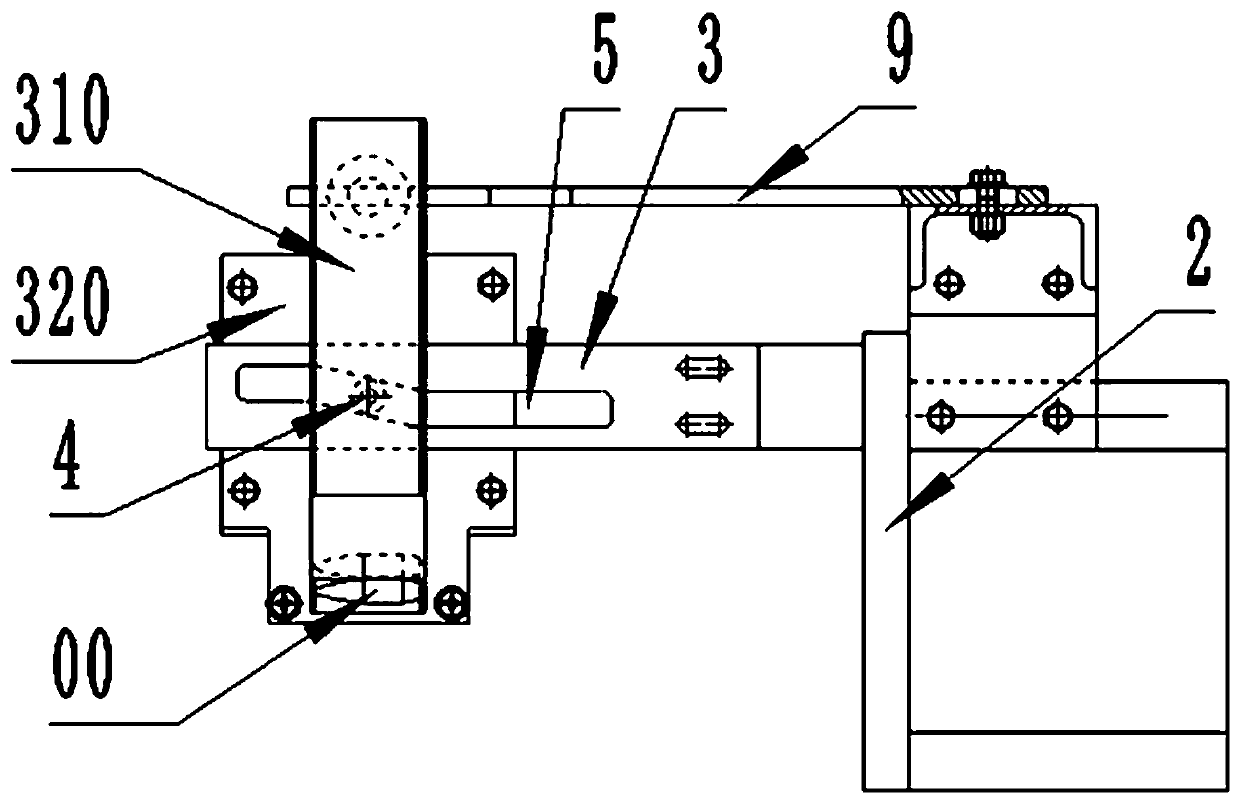

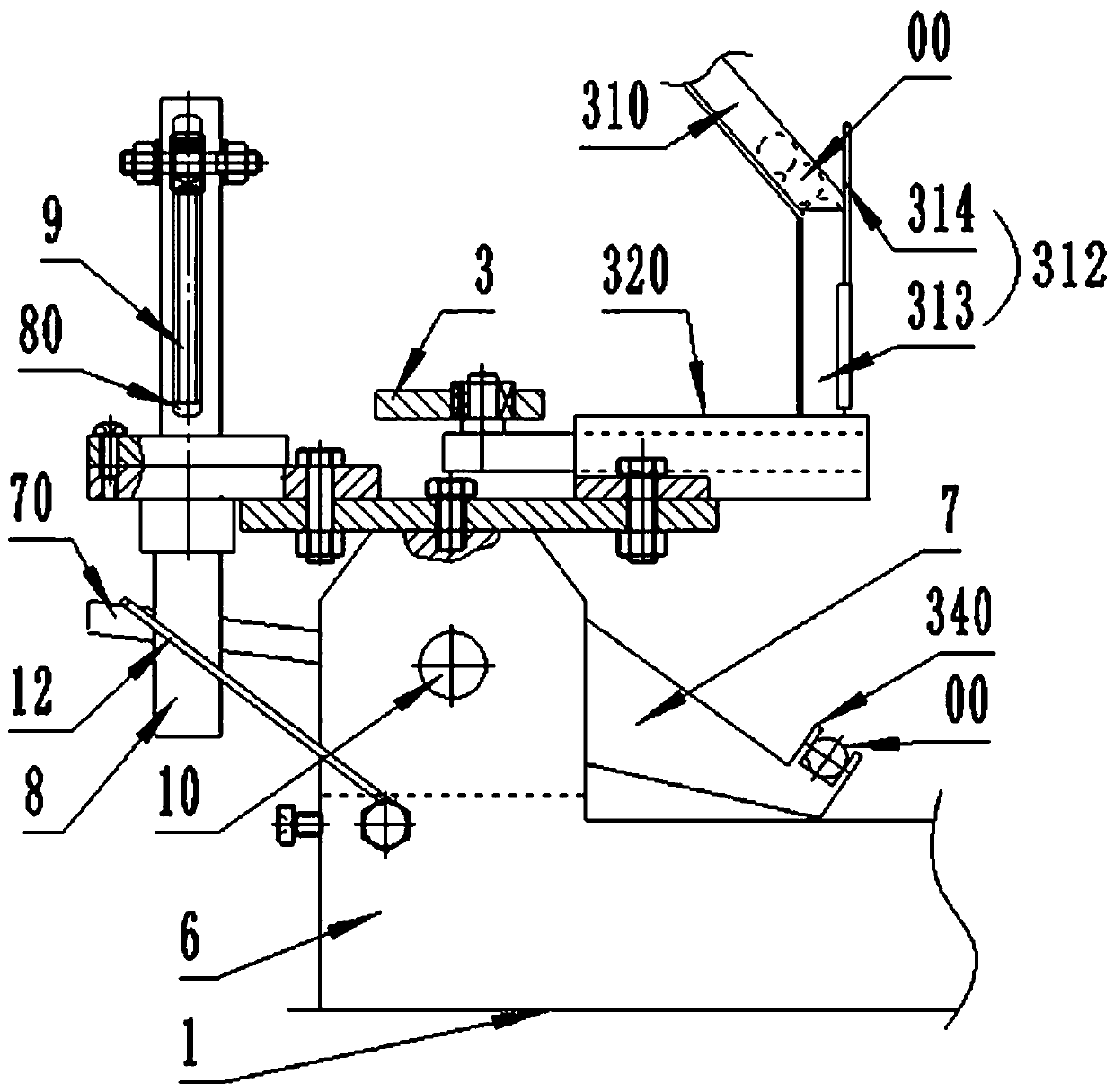

[0029] Such as figure 1 , 2 Shown is a projectile feeding device, the feeding device 300 includes a feeding chute 310 arranged on the bed 1, a material spacer 320 for pushing the projectile 00 to the outlet at the lower end of the feeding chute 310, and a The material support 330 supporting the projectile 00 is connected to the lifting mechanism for making it docked with the discharge port of the feeding chute 310; the lower end of the feeding chute 3...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap