Wafer three-sided cutting method

A cutting method and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of reducing the reliability of subsequent processes, increasing the difficulty of operations, and affecting production capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

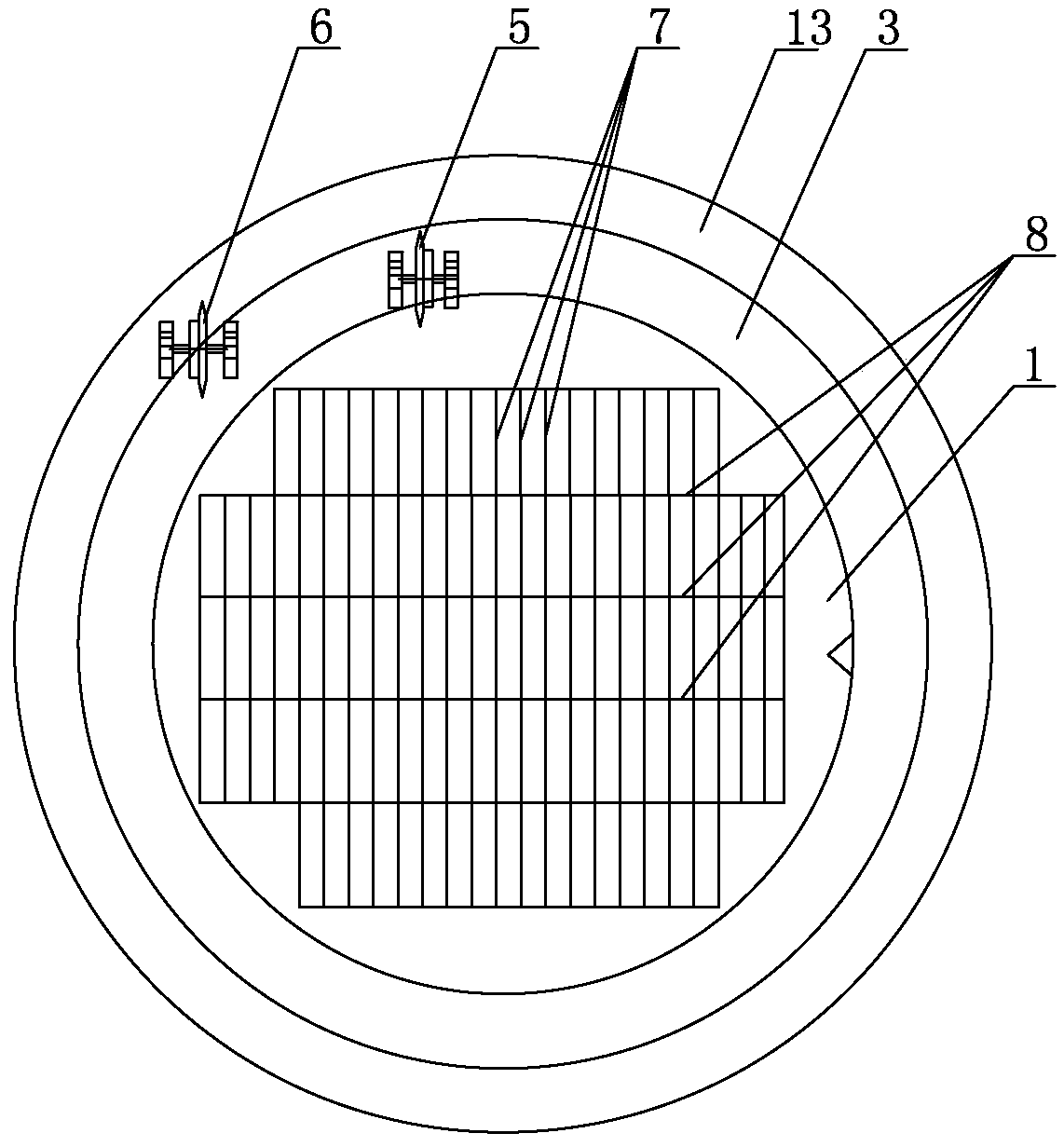

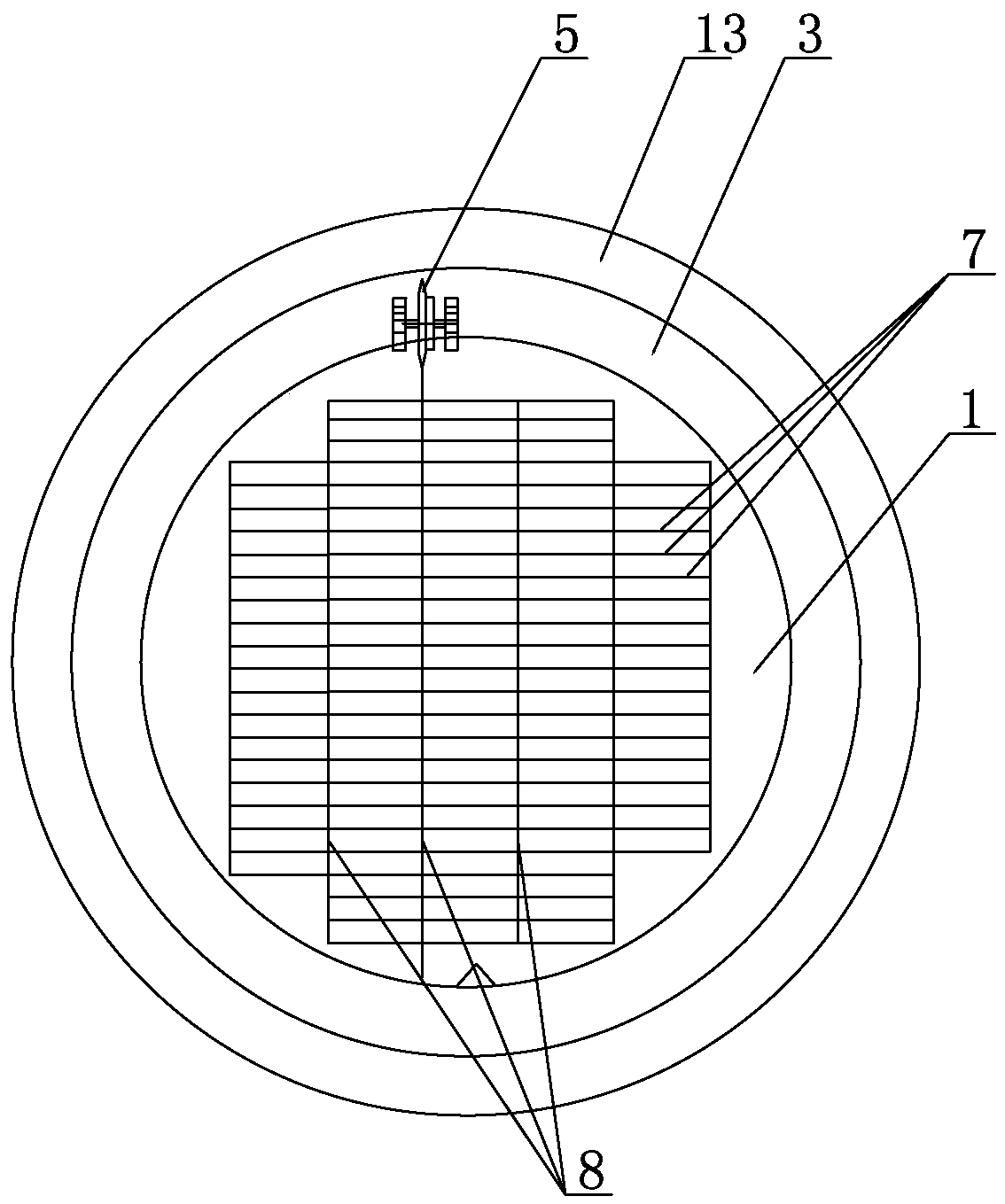

[0034] Such as Figure 2-11 As shown, it is a three-side cutting method of a wafer, including the following steps:

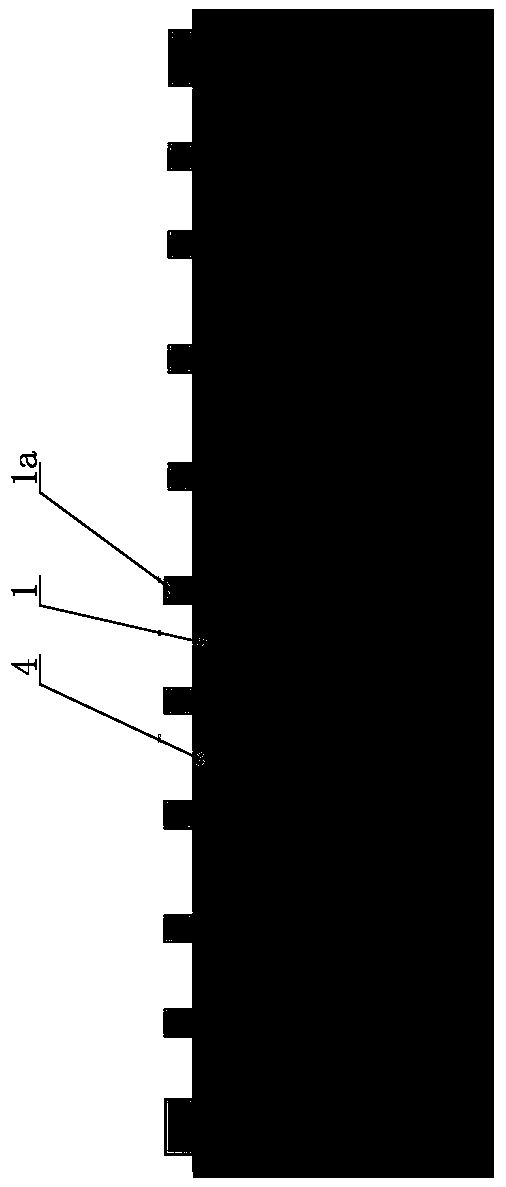

[0035] (1) Provide a wafer 1, the diameter of the wafer 1 is 203 or 305 mm; the surface of the wafer 1 is provided with gold bumps 1a; the wafer 1 is fixed on the adhesive film layer 3 through the adhesive layer 2 , the surface area of the adhesive film layer 3 is greater than the surface area of the wafer 1, the center of the wafer 1 and the adhesive film layer 3 overlaps, the outer peripheral edge of the adhesive film layer 3 is fixed with an outer frame, and the surface of the wafer 1 is covered with a passivation protection layer 4;

[0036] (2) The wafer 1 is transported to the rotatable wafer 1 stage located under the cutting mechanism. The wafer 1 is placed horizontally. The wafer 1 is set corresponding to the cutting mechanism. The cutting mechanism includes a laterally movable knife seat 1 and Knife seat two, there is a transverse distance between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com