Active material body for a battery

A technology of active materials and storage batteries, applied in the direction of lithium storage batteries, non-aqueous electrolyte storage batteries, non-aqueous electrolyte storage battery electrodes, etc., which can solve the problems of shortened battery life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

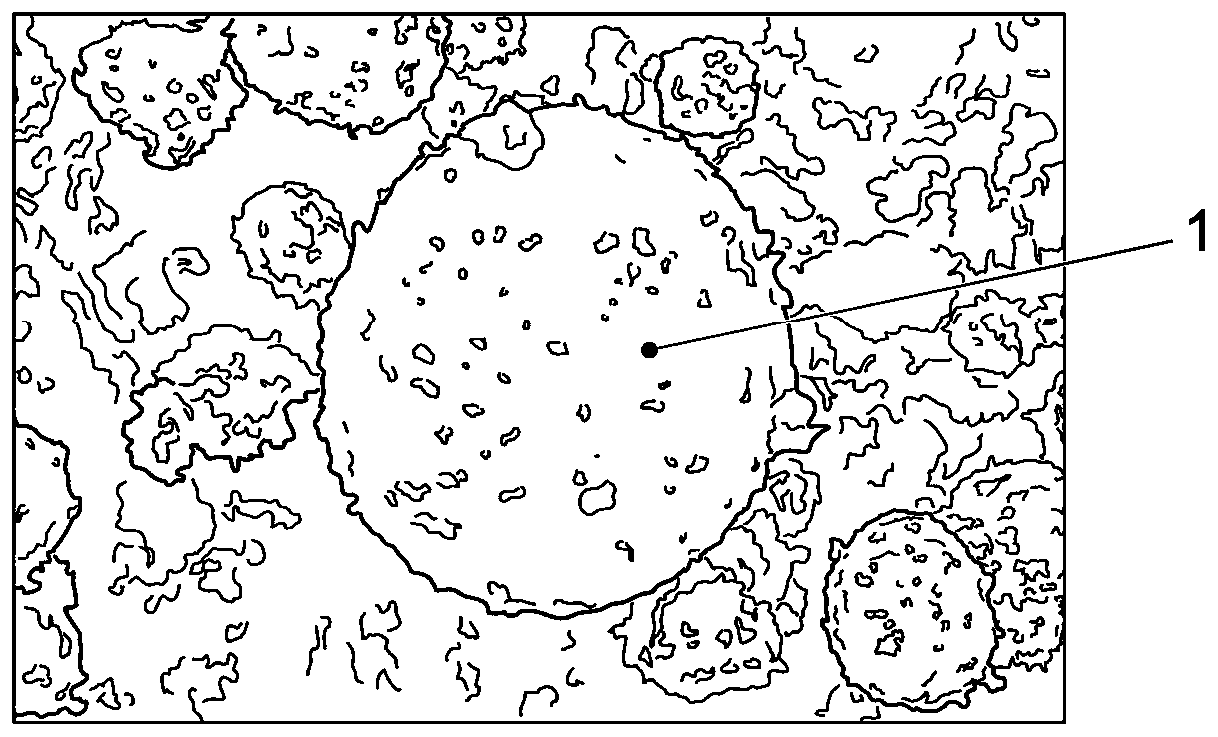

[0065] figure 1 Active material body 1 (cathode material here) is shown in a scanning electron microscope (SEM) photograph.

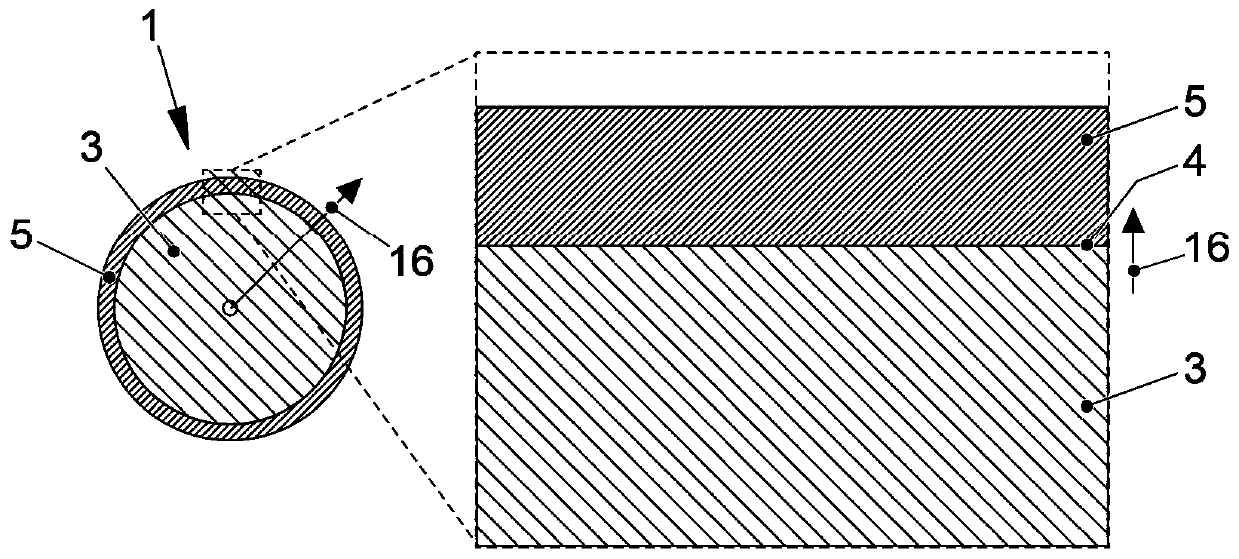

[0066] figure 2 A first embodiment variant of an active material body 1 is shown which has an active material 3 and a first coating 5 on a surface 4 of the active material 3 . The first coating 5 is arranged outside the (spherical) active material 3 in the radial direction 16 .

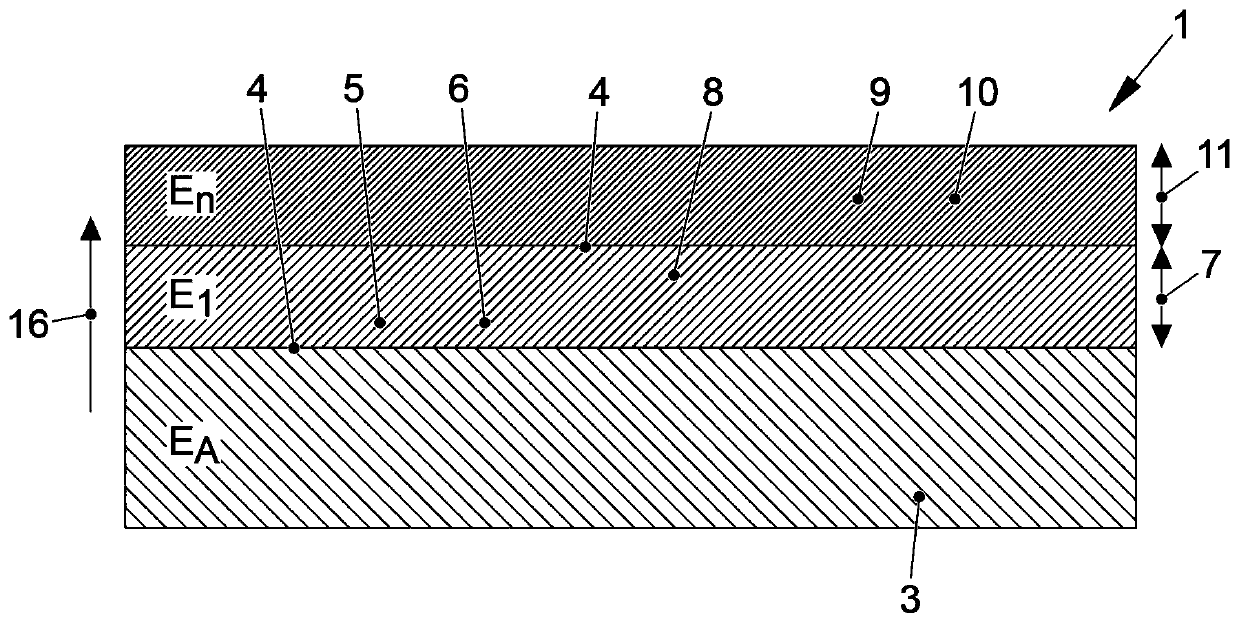

[0067] image 3 A second embodiment variant of the active material body 1 is shown. reference pair figure 2 instruction of.

[0068] The current active material body 1 has a first coating 5 , 8 with a first thickness 7 and a second coating 9 with a second thickness 11 . The first coating 5 , 8 comprises a first material 6 and the second coating 9 comprises a second thickness 11 . Starting from active material 3, the modulus of elasticity E A ,E 1 ,E 2 Decreases with each coat5,8,9.

[0069] Figure 4 A third embodiment variant of the active material body 1 is show...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com