Horizontal conical film evaporator

A thin-film evaporator and conical technology, which is applied in the field of horizontal conical thin-film evaporators, can solve the problems of poor distillation effect and poor defoaming effect, and achieve the effect of compact structure, small footprint and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

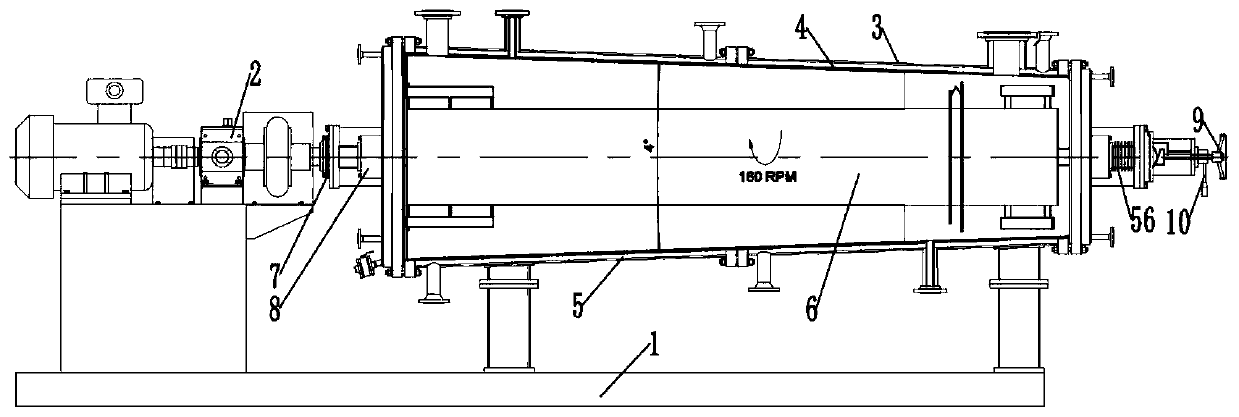

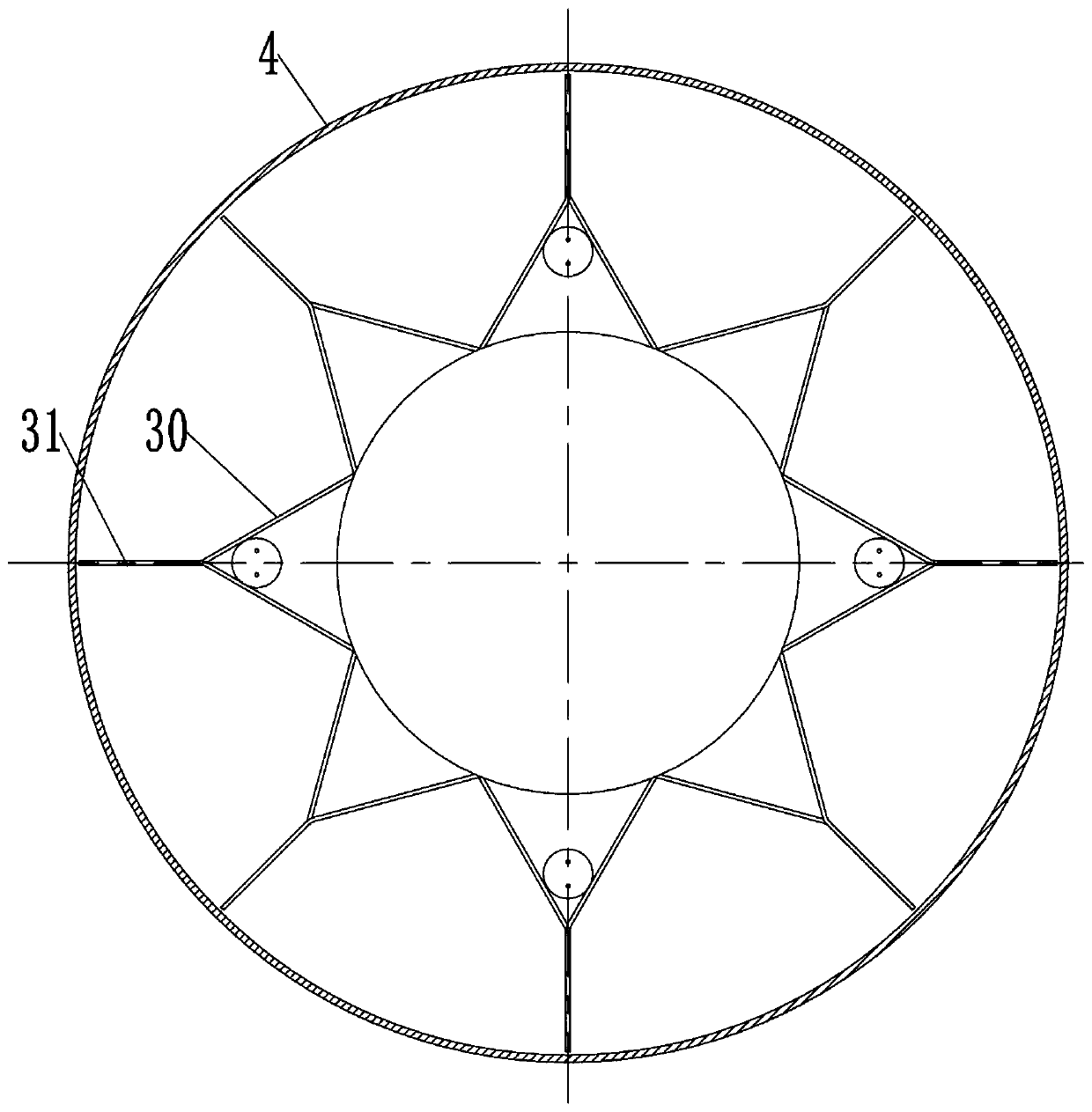

[0040] Such as Figure 1-7 As shown, the horizontal conical thin-film evaporator of this embodiment includes a frame base 1 as a support, a driving component 2 arranged on the frame base 1 to realize drive control, and a jacket 3 arranged on the frame base 1 as The outer support, the conical evaporation chamber 4 lying in the jacket 3 is used as the inner sleeve, and the taper is used to realize the gathering of the materials during the transmission, so as to realize the concentrated heating of the materials by the accumulation of heat. The heat flow interlayer channel 5 between the chambers 4 realizes the flow heating of the heat flow (hot air flow or hot liquid), and rotates the rotor 6 arranged in the conical evaporation chamber 4 and communicated with the driving part 2, and the rotor 6 is provided with wings The sheet realizes that the material moves forward during agitation.

[0041] The conical evaporation chamber 4 is divided into rear steam chamber 27, middle steam c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com