Clamping force display bench clamp

A clamping force and vise technology, applied in the field of clamping force display vise, can solve the problems of reduced machining accuracy, loose parts, damaged parts, etc., to avoid deformation or damage, and avoid loosening.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

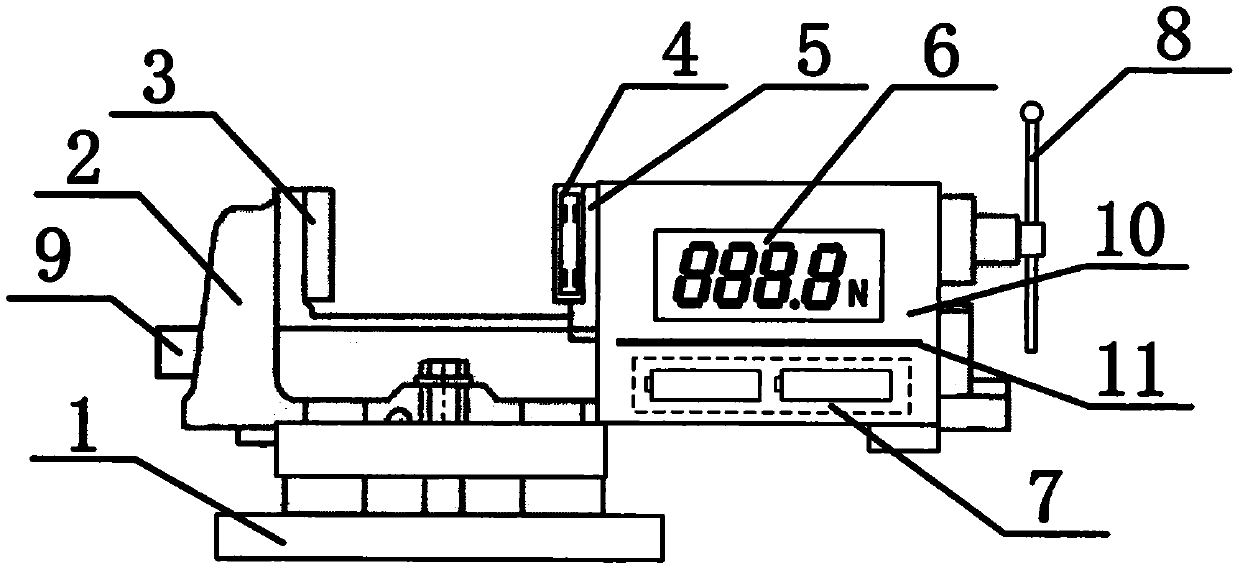

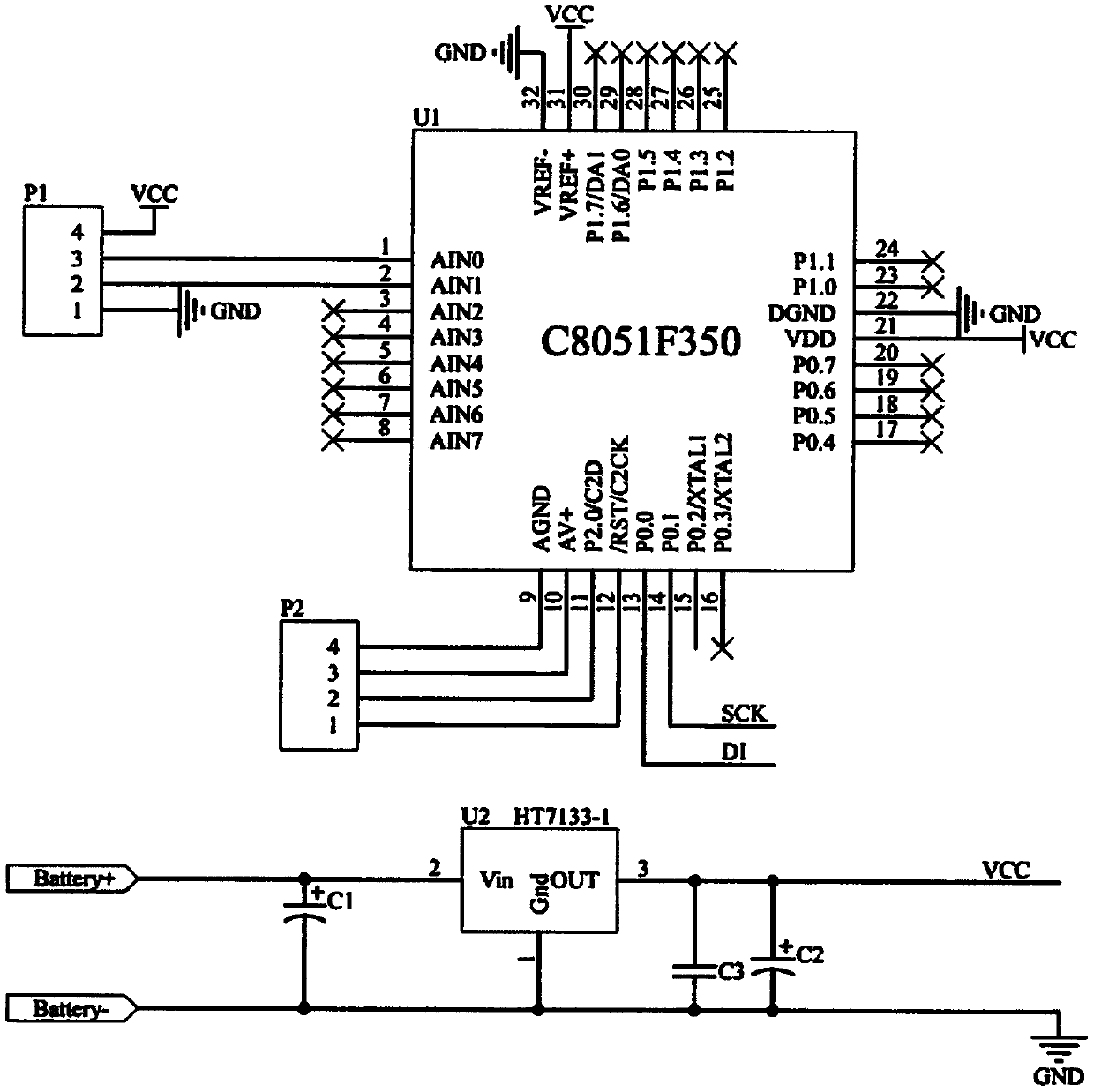

[0009] combined with Figure 1~2 The present invention is further described:

[0010] A clamping force display vise, its structure is shown as figure 1 As shown, it includes base 1, movable table 2, movable jaw 3, pressure sensor 4, fixed jaw 5, liquid crystal display 6, battery box 7, signal processing circuit board 11, wrench 8 and screw mandrel 9, described The base 1 is used to fix the vise on the operating table, and the movable jaw 3 is installed on the movable table 2. When the wrench 8 is turned clockwise, the movable jaw 3 is driven by the screw rod 9 to the fixed The jaw 5 moves in the direction of clamping the part; when the wrench 8 is turned counterclockwise, the movable jaw 3 moves away from the fixed jaw 5 under the drive of the screw 9, that is, the part is released; the pressure sensor 4 is installed on the inner side of the fixed jaw 5, the battery box 7, the liquid crystal display 6 and the signal processing circuit board 11 are all installed in the shell ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com