Sealing contactor disassembly device

A technology for sealing contact and disassembly devices, applied in electric heating devices, welding equipment, metal processing and other directions, can solve the problems of unrepairable products, zero, component deformation, increased labor intensity of workers and disassembly time, etc., to avoid deformation and damage. damage, reduce labor intensity, and operate safely

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

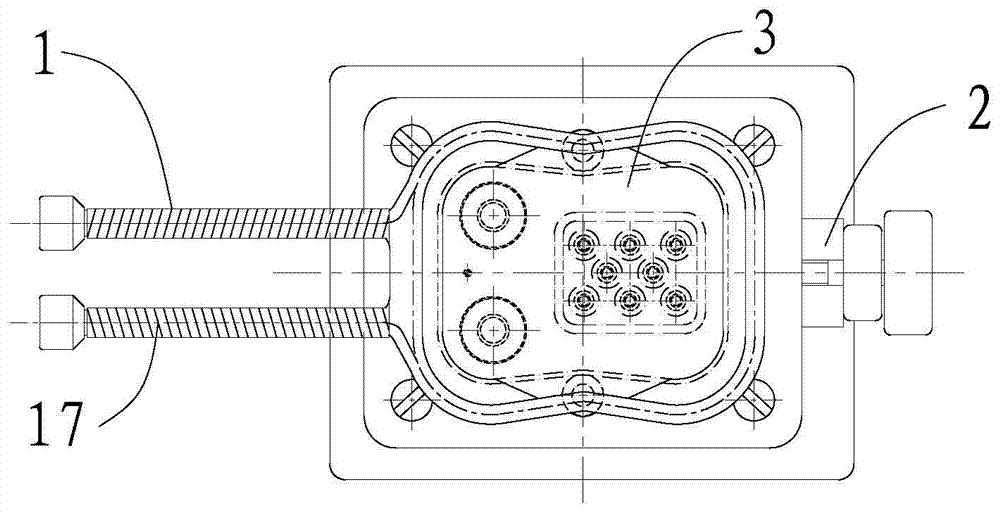

[0026] The idea of the present invention is to make full use of the two major effects (skin effect and proximity effect) in high-frequency heating to stimulate the thermal effect of the welded parts when they are induced; at the same time, use the disassembly fixture of the product to ensure The distance between the outer surface of the plate assembly and the inner surface of the high-frequency induction coil is uniform and stable, ensuring that the outer surface of the product will not be partially burned during the induction heating process.

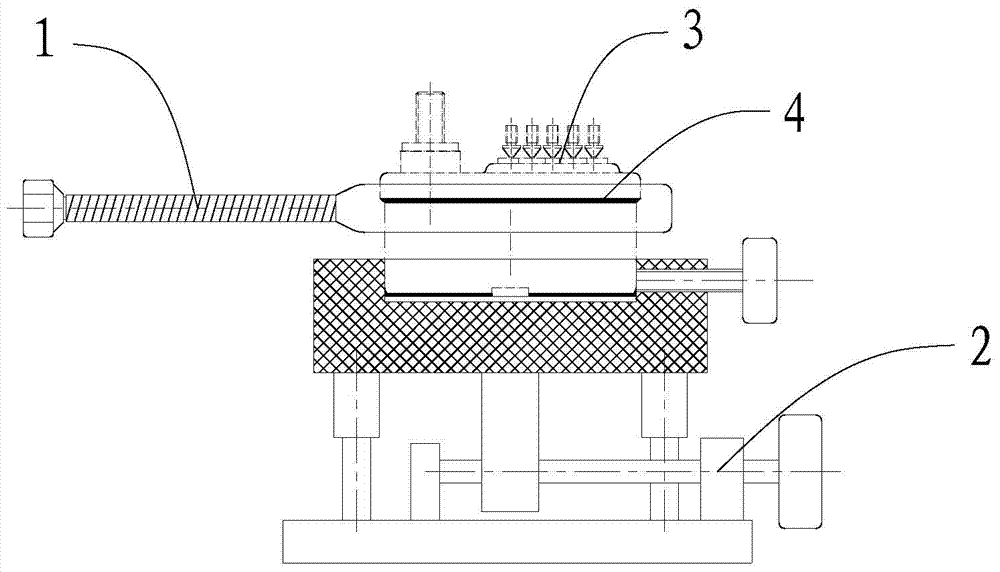

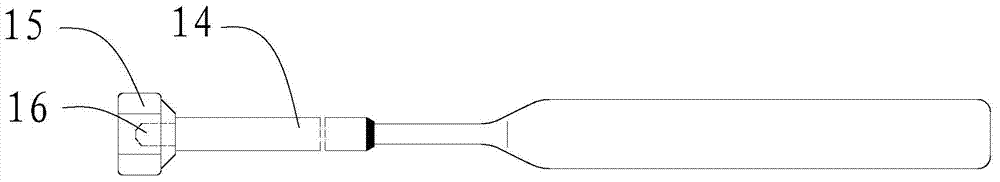

[0027] refer to Figure 1-2 As shown, the sealing contactor removal device of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com