Waterproof shielding protection film for spraying and processing technology thereof

A processing technology and technology of protective film, applied in the field of waterproof shielding protective film for spraying and its processing technology, can solve the problems of poor waterproof performance, deformation and damage, etc., achieve convenient processing efficiency, avoid deformation and damage, and ensure high temperature resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The invention provides a waterproof shielding protective film for spraying, which comprises: 41.70% polyethylene resin, 3.60% glucose, 0.30% antioxidant, 0.30% ultraviolet absorber, 23.50% composite filler, 30.60% organic solvent; the composite filler includes: 22.50% nano-silica aerogel, 21.50% polyurethane, 21.40% nano-silica, 16.40% polyacrylonitrile, 18.20% silver nitrate;

[0028] The organic solvent is one or more mixtures of butyl acetate, isobutyl acetate, ethyl acetate, n-propanol, and tert-butanol; the antioxidant is: antioxidant 164, antioxidant DLTP One or two compound formulations, the ultraviolet absorber is: 2-hydroxy-4-n-octyloxybenzophenone;

[0029] The present invention also provides a processing technology for waterproof shielding protective film for spraying, the specific processing steps are as follows:

[0030] Step 1: weighing the polyethylene resin, glucose, antioxidant, ultraviolet absorber, composite filler and organic solvent of the above w...

Embodiment 2

[0039] Different from Example 1, it includes: 42.50% polyethylene resin, 4.60% glucose, 0.50% antioxidant, 0.50% ultraviolet absorber, 24.30% composite filler, 27.60% organic solvent by weight percentage ; The composite filler includes: 23.30% nano-silica airgel, 22.30% polyurethane, 22.20% nano-silica, 18.20% polyacrylonitrile, 41.00% silver nitrate according to weight percentage.

Embodiment 3

[0041] All different from Examples 1-2, it includes: 42.10% polyethylene resin, 4.10% glucose, 0.40% antioxidant, 0.40% ultraviolet absorber, 23.90% composite filler, 29.10% organic solvent; the composite filler includes: 22.90% nano-silica aerogel, 21.90% polyurethane, 21.80% nano-silica, 17.30% polyacrylonitrile, 16.10% silver nitrate silicon.

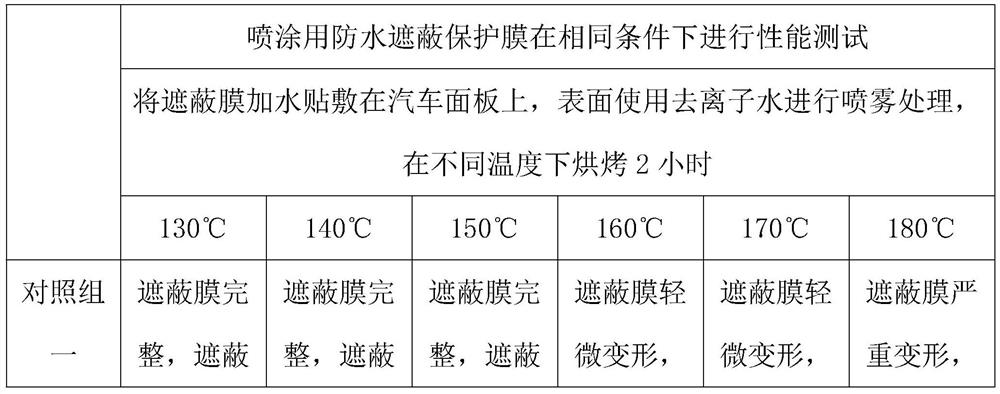

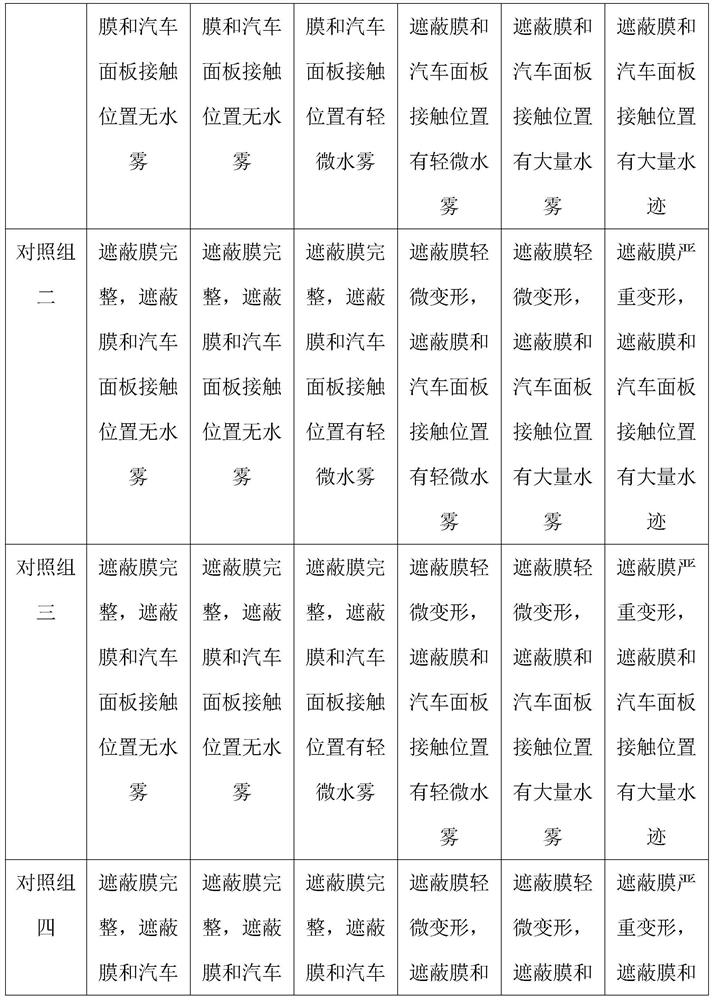

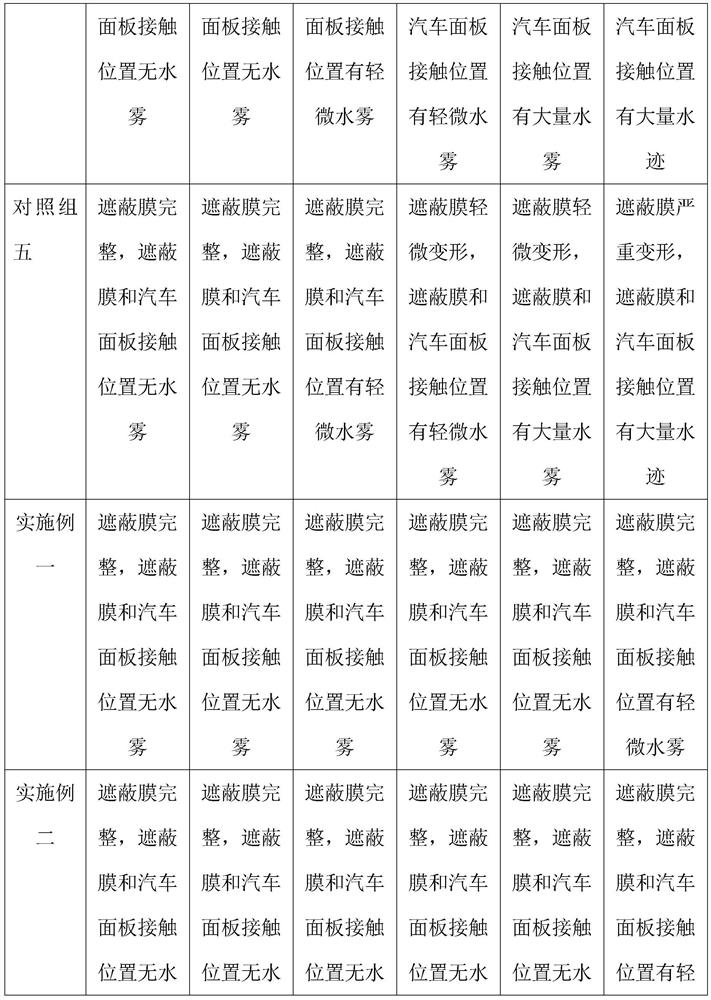

[0042] Get respectively the spraying waterproof shielding protective film that above-mentioned embodiment 1-3 makes and the spraying waterproof shielding protective film of control group one, the spraying waterproof shielding protective film of matching group two, the spraying waterproof shielding protective film of matching group three. The spraying of film, control group four uses waterproof shielding protective film and the spraying of matching group five uses waterproof shielding protective film, and the spraying of control group one uses waterproof shielding protective film compared with embodiment without nano-silica aerogel, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com