Assembled prefabricated sandwich insulation exterior wall vertical seam waterproof structure and implementation method

A technology for thermal insulation of external walls and waterproof structures, applied to building thermal insulation materials, walls, building components, etc., can solve problems such as hidden dangers, water seepage at seams, and greater impact on the operating environment, achieving excellent results, enhancing overall strength, The effect of excellent waterproof barrier effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

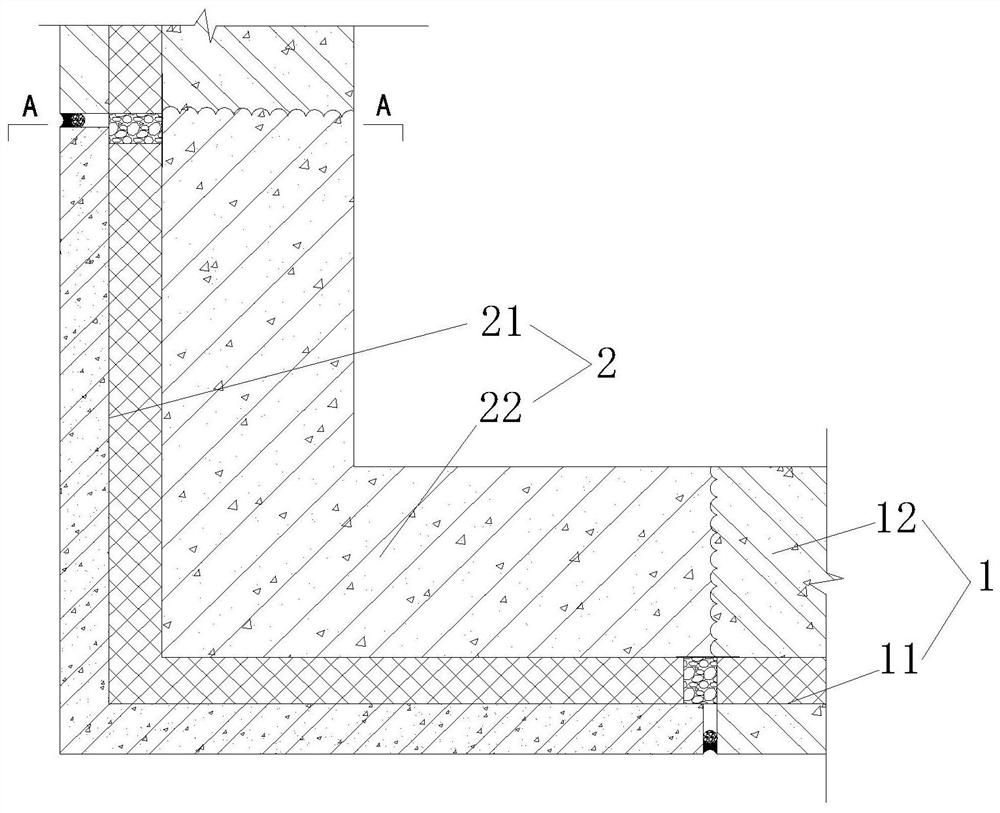

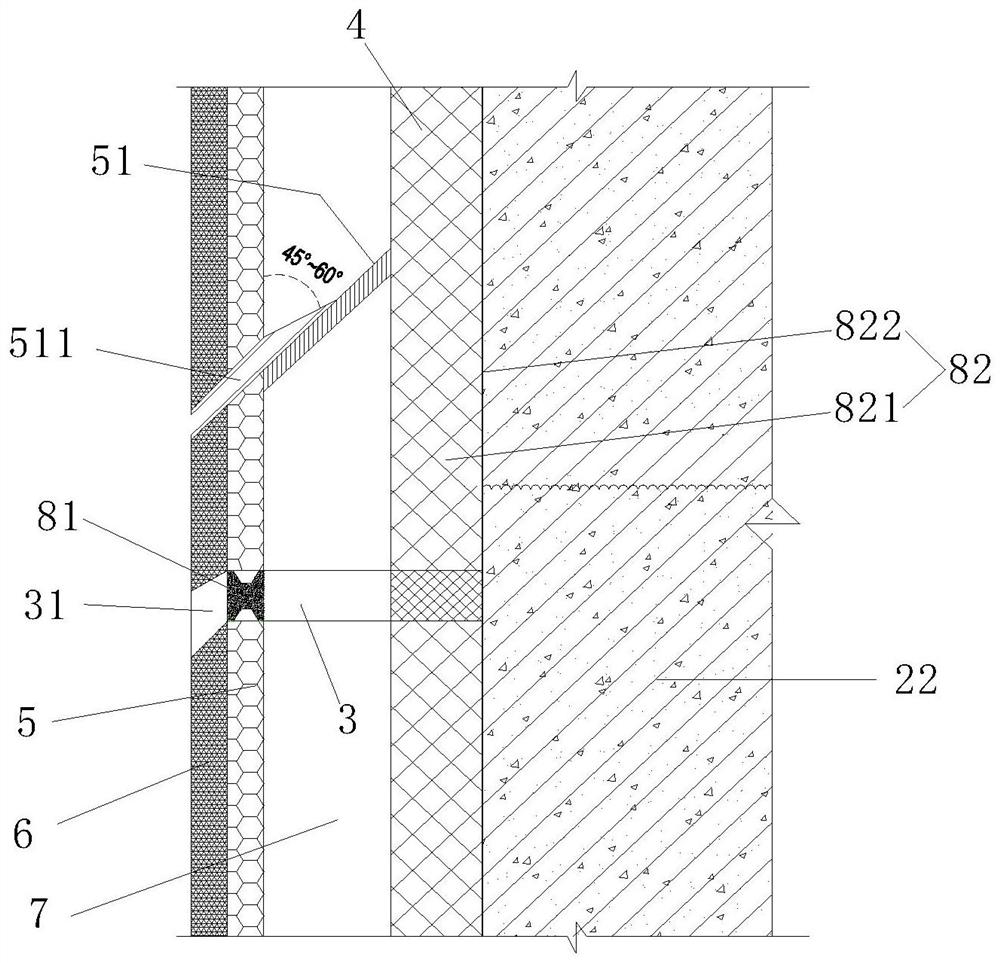

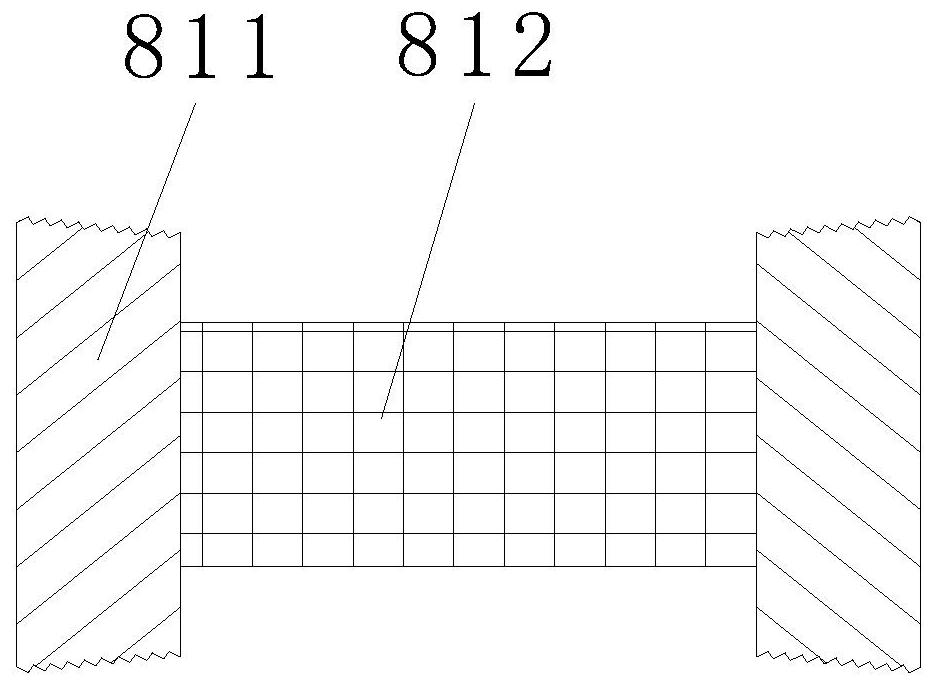

[0030] Such as Figure 1 to Figure 3 As shown, the waterproof structure includes a prefabricated exterior wall panel 1, a cast-in-place exterior wall panel 2, and a horizontal seam 3 reserved between the prefabricated exterior wall panel 1 and the cast-in-place exterior wall panel 2, and the prefabricated exterior wall panel 1 Including the integrally connected first PCF exterior wall template 11 and prefabricated concrete slab 12, the cast-in-place exterior wall panel 2 includes the integrally connected second PCF exterior wall template 21 and cast-in-place concrete 22, the first PCF exterior wall template 11 and the second The PCF exterior wall formwork 21 is spliced, the prefabricated concrete slab 12 and the cast-in-place concrete 22 are spliced through the corrugated surface, and the first PCF exterior wall formwork 11 and the second PCF exterior wall formwork 21 include the insulation layer 4 and the backing material sequentially from the inside to the outside 5 and th...

Embodiment 2

[0035] Such as Figure 4 As shown, the difference from Embodiment 1 is that the horizontal drainage cavity 31 is a stepped structure gradually increasing from the outside to the inside, and the concealed backing 81 is arranged on the lowest surface of the stepped structure, and the waterproof component 82 is located on the highest surface, thereby achieving high efficiency. Waterproof structure.

Embodiment 3

[0037] Such as Figure 1 to Figure 4 Shown, the implementation method of this waterproof structure comprises the following steps:

[0038] Step 1, install the second PCF exterior wall formwork 21 of the prefabricated exterior wall panel 1 and the cast-in-place exterior wall panel 2 and the interior wall support formwork and calibrate the verticality;

[0039] Step 2, grinding the joint of the prefabricated concrete slab 12 and the cast-in-place concrete 22 into a corrugated surface;

[0040] Step 3: Fill the polyethylene foam strip 821 of the waterproof assembly 82 of the same material and equal thickness between the insulation boards on the first PCF exterior wall formwork 11 and the second PCF exterior wall formwork 21, prefabricated concrete slab 12 and cast-in-place concrete The joint surface of 22 is covered with self-adhesive butyl tape 822. The self-adhesive butyl tape 822 is bonded to both sides of the joint of precast concrete slab 12 and cast-in-place concrete 22 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com