Collapse treatment method of tunnel in water-rich faulted zone

A treatment method and tunnel technology, which is applied in tunnels, tunnel linings, drainage, etc., can solve the problems of increasing secondary landslides and increasing water pressure, and achieve the effect of reducing construction, small excavation surface, and reducing the probability of secondary landslides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

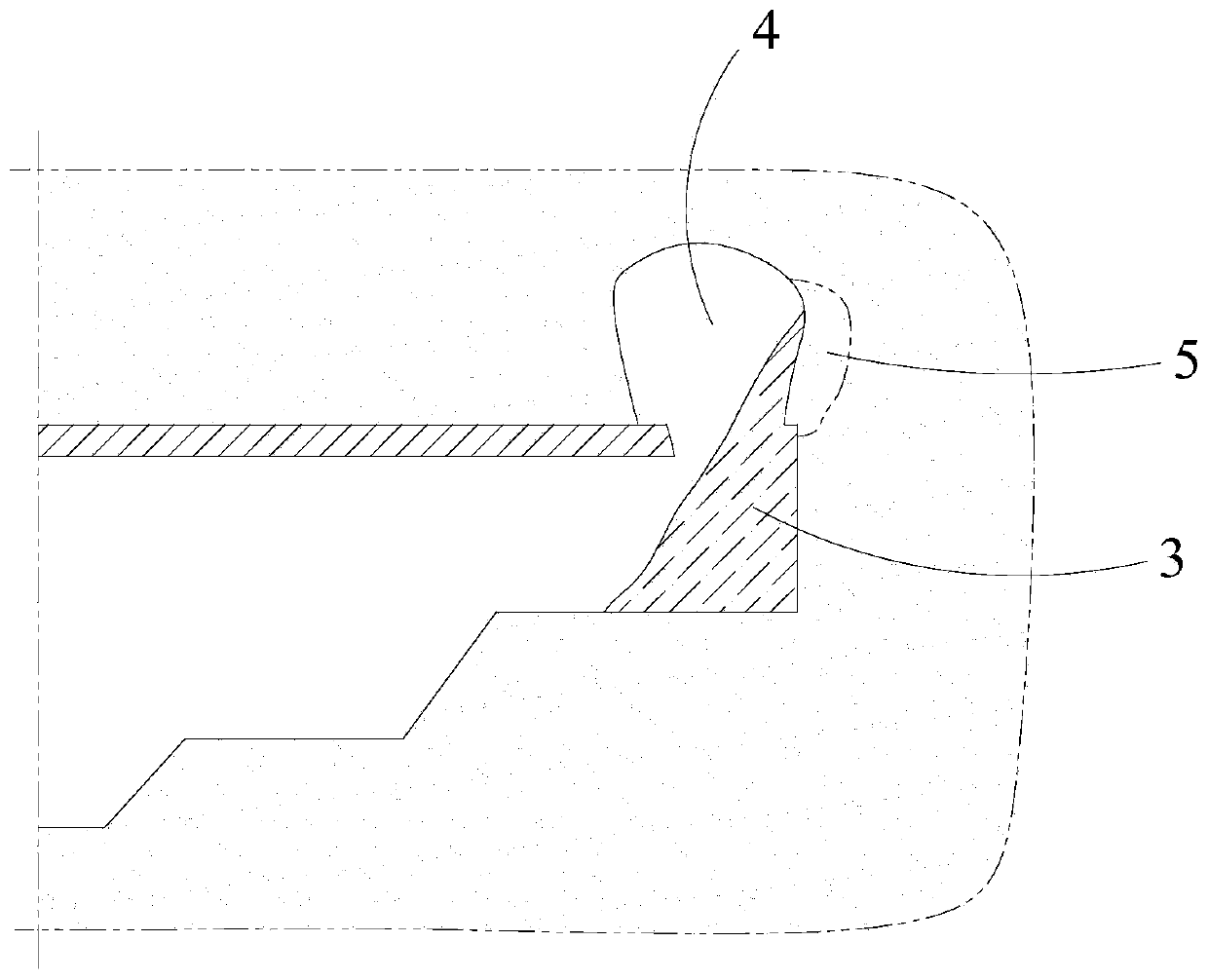

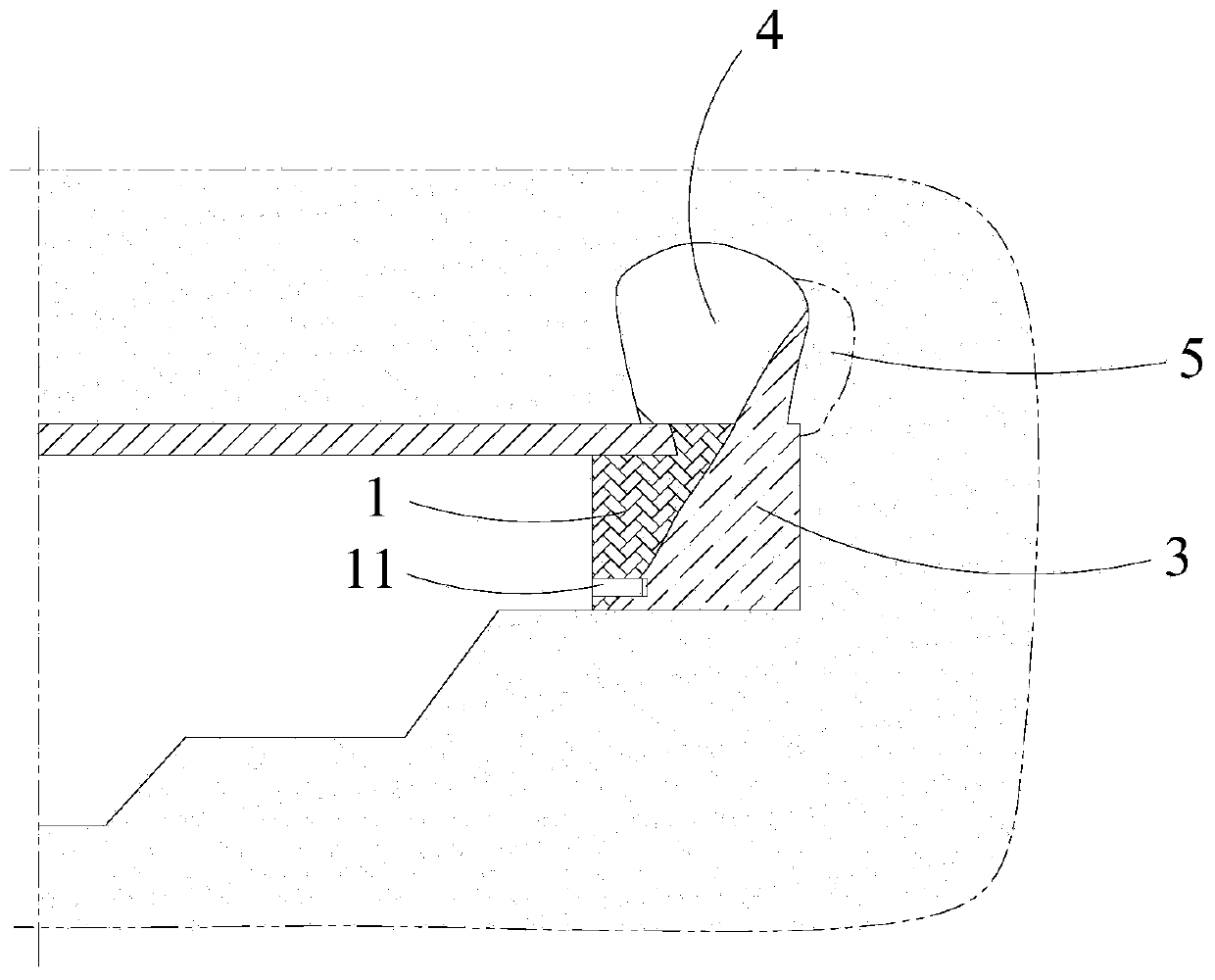

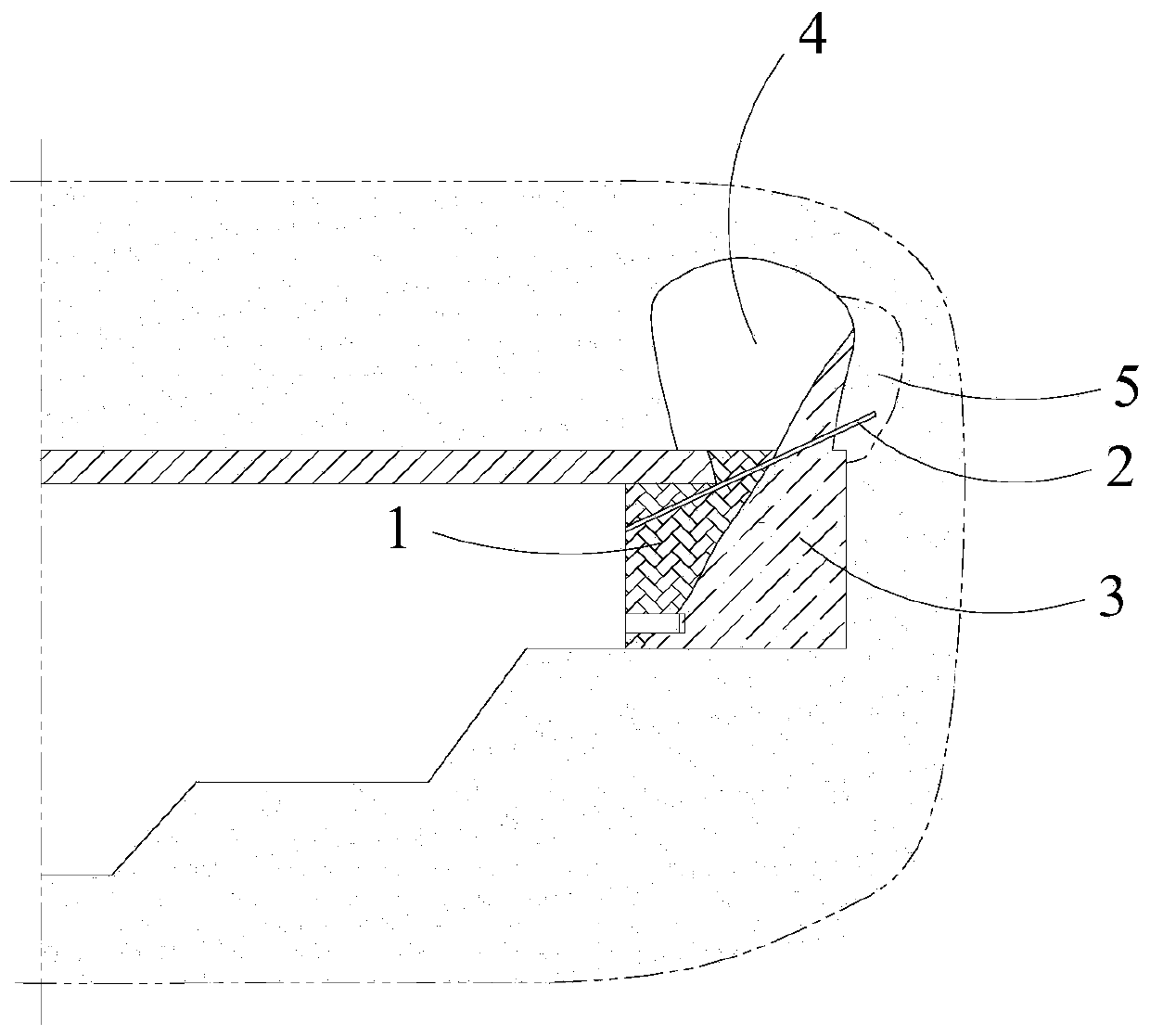

[0053] Such as Figure 2-7 Shown, a kind of tunnel collapse treatment method for the water-rich fault zone comprises the following steps:

[0054] S1. Pour a grout-stop wall 1 close to the landslide soil area 3, on which the grout-stop wall 1 is provided with at least one drainage pipe 11 passing through the grout-stop wall 1, and the grout-stop wall 1 passes through the anchor rod and the tunnel The side walls are connected;

[0055] S2. Drill a number of first placement holes connecting the loose soil area 5 on the grout stop wall 1, and place a first grouting pipe 2 in each of the first placement holes, and the first grouting pipe 2 The front end extends into the loosening area 5;

[0056] S3. Grouting the soil loosening area 5 through the first grouting pipe 2, making the grouting pressure reach a first threshold, and stabilizing the pressure as required;

[0057] S4. Excavating the grout stop wall 1 and the landslide soil area 3, and performing arch support;

[0058] ...

Embodiment 2

[0079] Such as Figure 9 As shown, in the method for treating tunnel collapse in a water-rich fault zone as described in Example 1, in step S3, after the grouting is completed, the exhaust valve 26 is closed first, and then the grouting valve 25 is closed.

[0080] Wherein, the first grouting pipe 2 is a hollow steel pipe, and the front end is pointed. The first grouting pipe 2 is provided with a grouting chamber 21 and an exhaust chamber 22. The first grouting pipe 2 At least one grouting hole 23 and at least one exhaust hole 24 are provided on the front end side wall of the front end, the grouting hole 23 communicates with the grouting cavity 21, and the exhaust hole 24 communicates with the exhaust cavity 22 connected.

[0081] The rear end of the first grouting pipe 2 is respectively connected with a grouting valve 25 and an exhaust valve 26, the grouting valve 25 communicates with the grouting cavity 21, and the exhaust valve 26 communicates with the exhaust valve 26. T...

Embodiment 3

[0084] Such as Figure 4 and 5 As shown, as described in Embodiment 1 or 2, a method for treating tunnel collapses in water-rich fault zones, in step S4, the three-step seven-step method is used to treat the grout-stop wall 1 and the landslide soil area 3 Carry out excavation construction.

[0085] The three-step seven-step method has a small excavation surface and is less difficult to deal with emergencies, which can ensure construction safety to the greatest extent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com