Construction method of the middle wall of the upper step of the tunnel crossing the stratum fracture zone

A construction method and technology of crushing zone, applied in the direction of tunnel, tunnel lining, earthwork drilling, etc., can solve the problems of restricting construction period, distortion of arch frame, distortion and deformation of steel frame, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

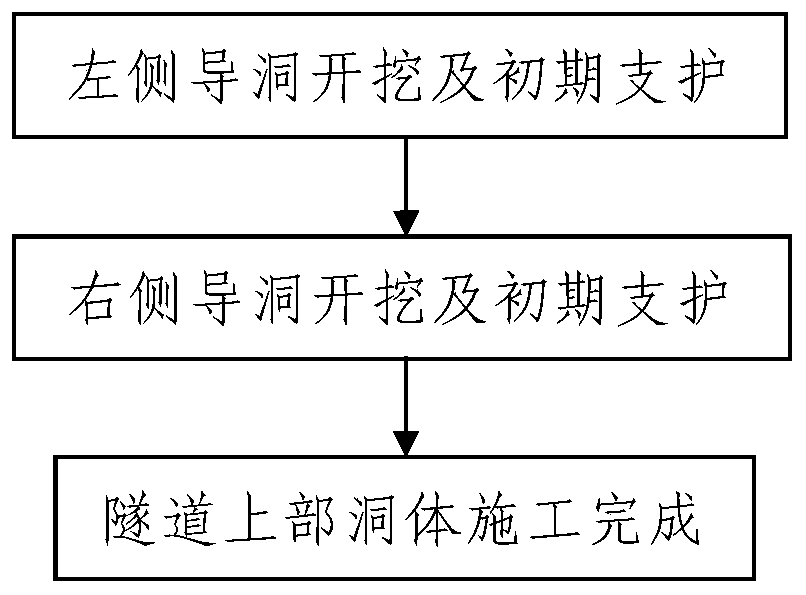

[0076] Such as figure 1 Shown is a construction method for the middle partition of the upper step of the tunnel passing through the stratum fracture zone, excavating the upper step of the constructed tunnel from the back to the front along the longitudinal extension direction of the tunnel, and obtaining the excavated and formed upper tunnel body 1;

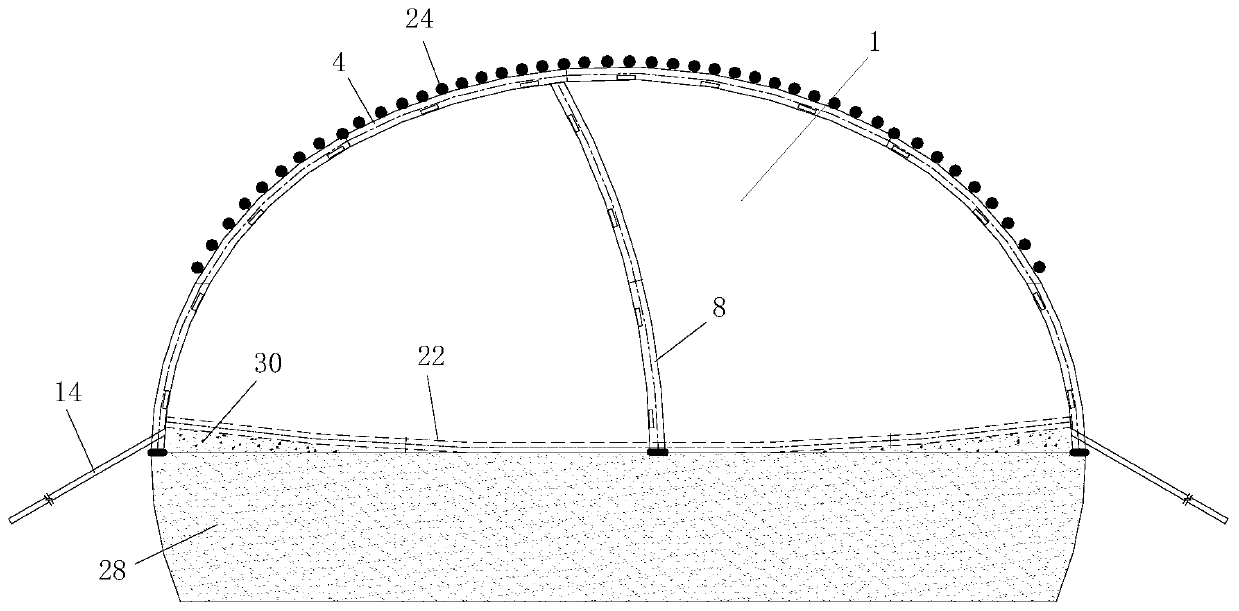

[0077] The tunnel being constructed is a large-section tunnel, and its tunnel hole includes a tunnel upper hole body 1 and a tunnel lower hole body located below the tunnel upper hole body 1, and a middle partition wall temporary support structure is arranged inside the tunnel upper hole body 1; The upper tunnel body 1 of the tunnel includes a left pilot tunnel and a right pilot tunnel located on the right side of the left pilot tunnel, and the temporary support structure of the middle partition wall is located between the left pilot tunnel and the right pilot tunnel. For details, see figure 2 ;

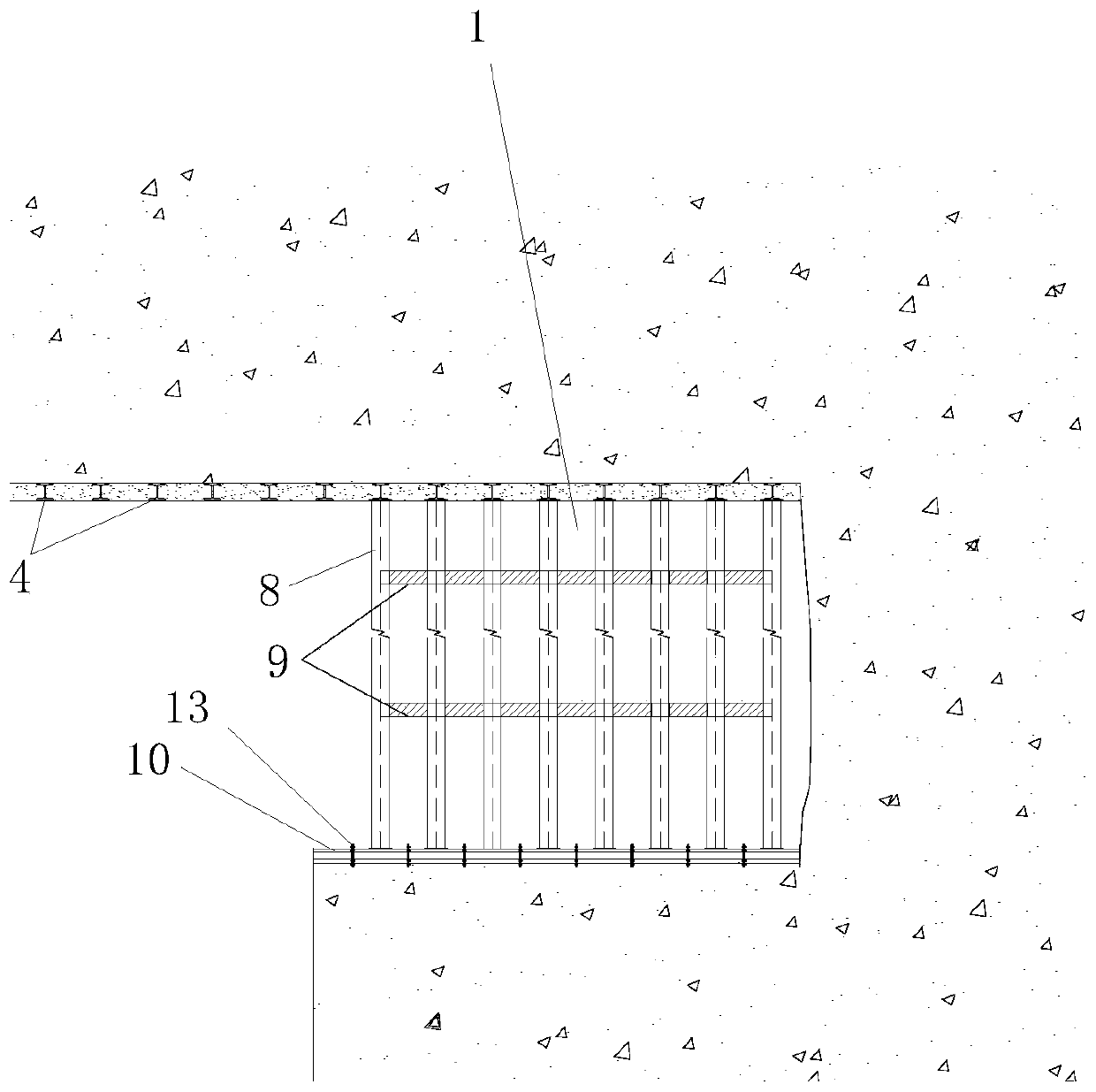

[0078] The initial tunnel supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com