Excavation and support methods for large-section tunnels crossing fault fracture zone

A technology of tunnel excavation and large cross-section, applied in tunnels, tunnel linings, earthwork drilling, etc., can solve the problems of large-scale encroachment of surrounding rock, restricted construction period, and inability to guarantee safety and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

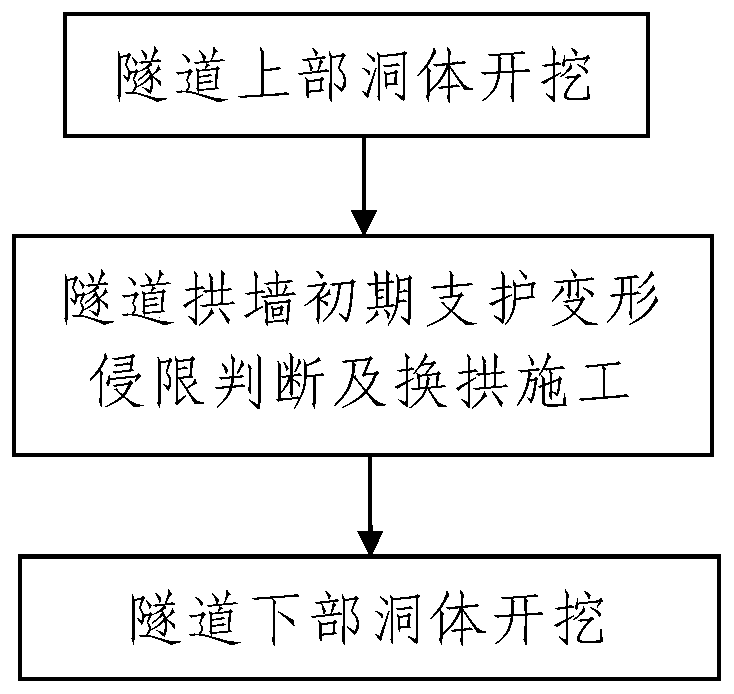

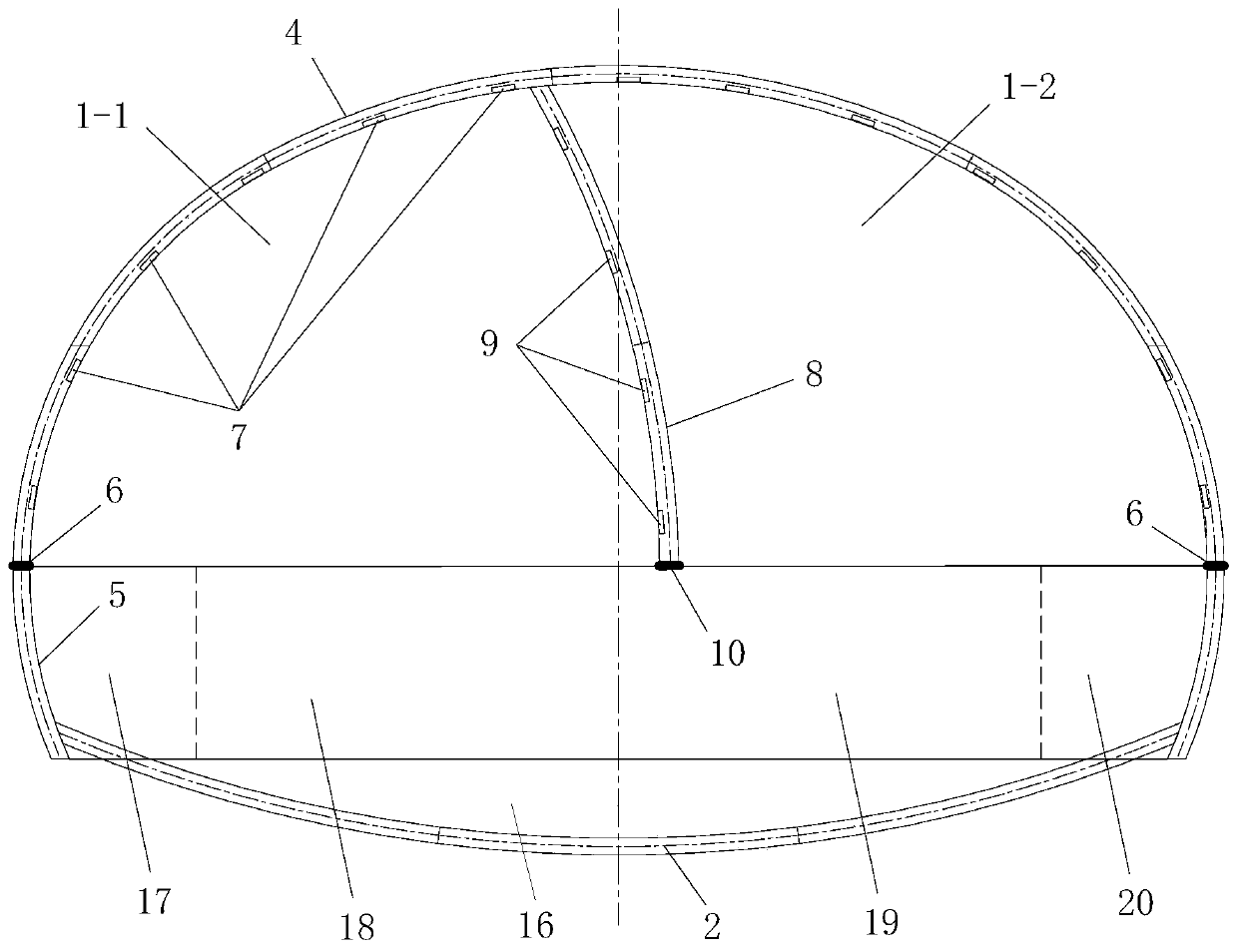

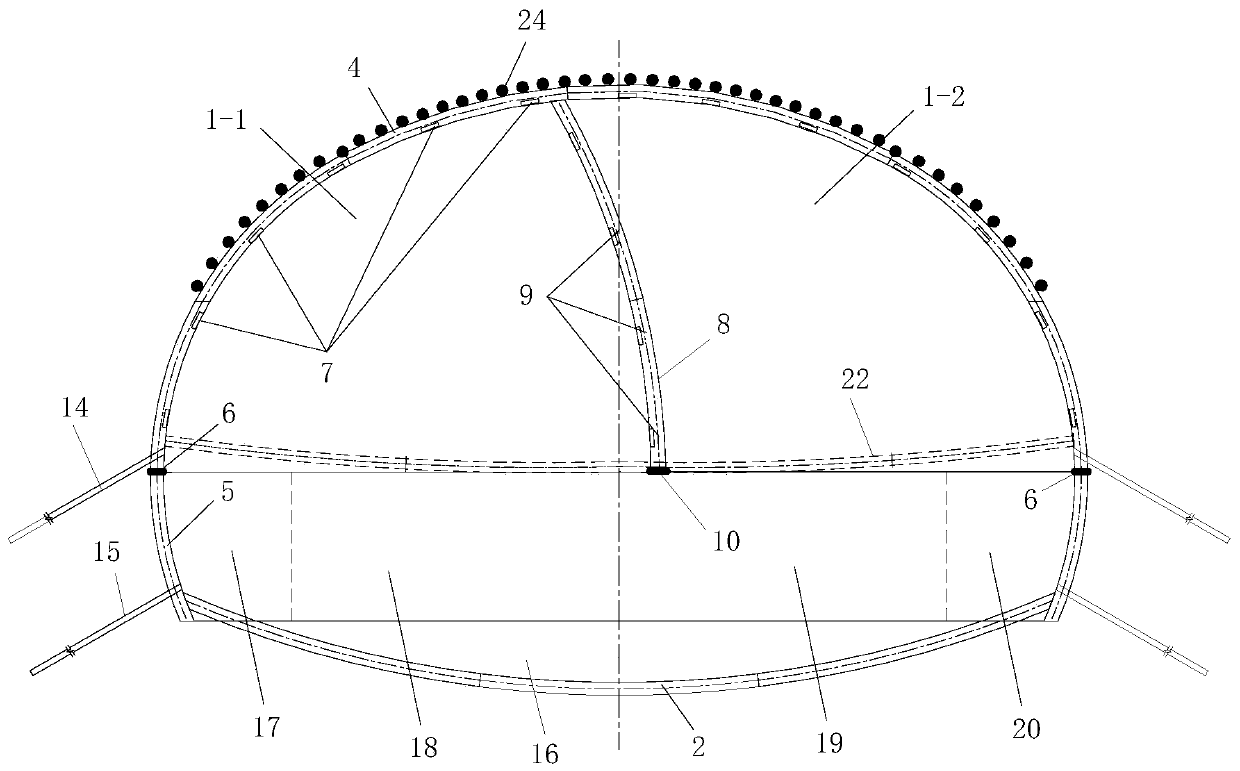

[0093] Such as figure 1 Shown is a method for excavating and supporting a large-section tunnel crossing a fault fracture zone. The tunnel hole of the constructed large-section tunnel includes a tunnel upper hole body 1 and a tunnel lower hole body located below the tunnel upper hole body 1. The tunnel The upper cave body 1 includes a left pilot tunnel 1-1 and a right pilot tunnel 1-2 on the right side of the left pilot tunnel 1-1, see figure 2 ;

[0094] The initial support structure of the tunnel hole includes a full-section support system for the full-section support of the tunnel hole and a tunnel bolt-net spray support structure for the initial support of the arch wall of the tunnel hole. Between the left pilot tunnel 1-1 and the right pilot tunnel 1-2, there is a temporary support structure for the intermediate partition wall. The temporary support structure for the intermediate partition wall is located in the upper tunnel body 1 of the tunnel and is located Inside th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com