Micro-electric precharge activation method for lithium ion battery

A technology of lithium ion battery and activation method, applied in the field of lithium ion battery formation, can solve the problems of unstable SEI film, affecting battery performance, etc., and achieve short precharge time, improve yield, and reduce metal impurities to form metal dendrites. effect of probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, a 18650 lithium-ion battery is used as the experimental battery, and the battery is selected from the AWA17K07XA batch, with a total of 57548pcs. Its battery parameters are: capacity 2400mAh, positive surface density of the battery is 440±8.8g / m 2 , negative surface density is 219.6±3.9g / m 2 , the thickness of the diaphragm is 18 μm, and the injection volume is 5.25±0.2g.

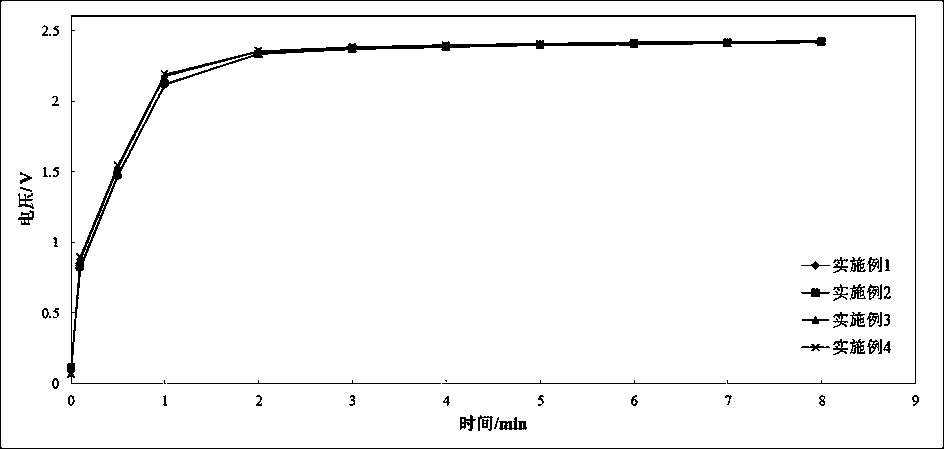

[0028] Select 23571pcs of them for micro-electric pre-charge activation. The specific steps are: charge the cleaned lithium-ion battery with a micro-current constant current with a charge rate of 0.05C, a charge voltage of 2.4V, and a charge time of 8 minutes; Aging at low temperature for 24 hours, followed by further aging at 25°C for 24 hours, that is, the micro-electricity pre-charge activation process is completed. Then charge the battery to full charge, age, and then perform self-discharge settlement, and calculate the self-discharge rate.

Embodiment 2

[0032] In this embodiment, a 18650 lithium-ion battery is used as the experimental battery, and the battery is selected from the AWA17K07XB batch, with a total of 58200pcs. Its battery parameters are: capacity 2400mAh, positive surface density of the battery is 440±8.8g / m 2 , negative surface density is 219.6±3.9g / m 2 , the thickness of the diaphragm is 18 μm, and the injection volume is 5.25±0.2g.

[0033] Select 23491pcs of them for pre-charging and activation of micro-electricity. The specific steps are: charge the cleaned lithium-ion battery with a micro-current constant current charging rate of 0.05C, the charging voltage is 2.4V, and the charging time is 8min; Aging at low temperature for 24 hours, followed by further aging at 25°C for 24 hours, that is, the micro-electricity pre-charge activation process is completed. Then charge the battery to full charge, age, and then perform self-discharge settlement, and calculate the self-discharge rate.

Embodiment 3

[0037] In this embodiment, a 18650 lithium-ion battery is used as the experimental battery, and the battery is selected from the AWA17K18XA batch, with a total of 60225pcs. The battery parameter is a capacity of 2400mAh, and the positive surface density of the battery is 440±8.8g / m 2 , the surface density of the negative electrode is 220.8±4.3g / m 2 , the thickness of the diaphragm is 20μm, and the injection volume is 5.25±0.2g.

[0038]Select 22640pcs of them for pre-charging and activation of micro-electricity. The specific steps are: charge the cleaned lithium-ion battery with a micro-current constant current charging rate of 0.05C, the charging voltage is 2.4V, and the charging time is 8min; Aging at low temperature for 24 hours, followed by further aging at 25°C for 24 hours, that is, the micro-electricity pre-charge activation process is completed. Then charge the battery to full charge, age, and then perform self-discharge settlement, and calculate the self-discharge r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com