Method for operating converter furnace

An operation method and converter technology, applied in furnaces, electric furnaces, furnace types, etc., can solve problems such as iron content increase, and achieve the effect of suppressing swing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

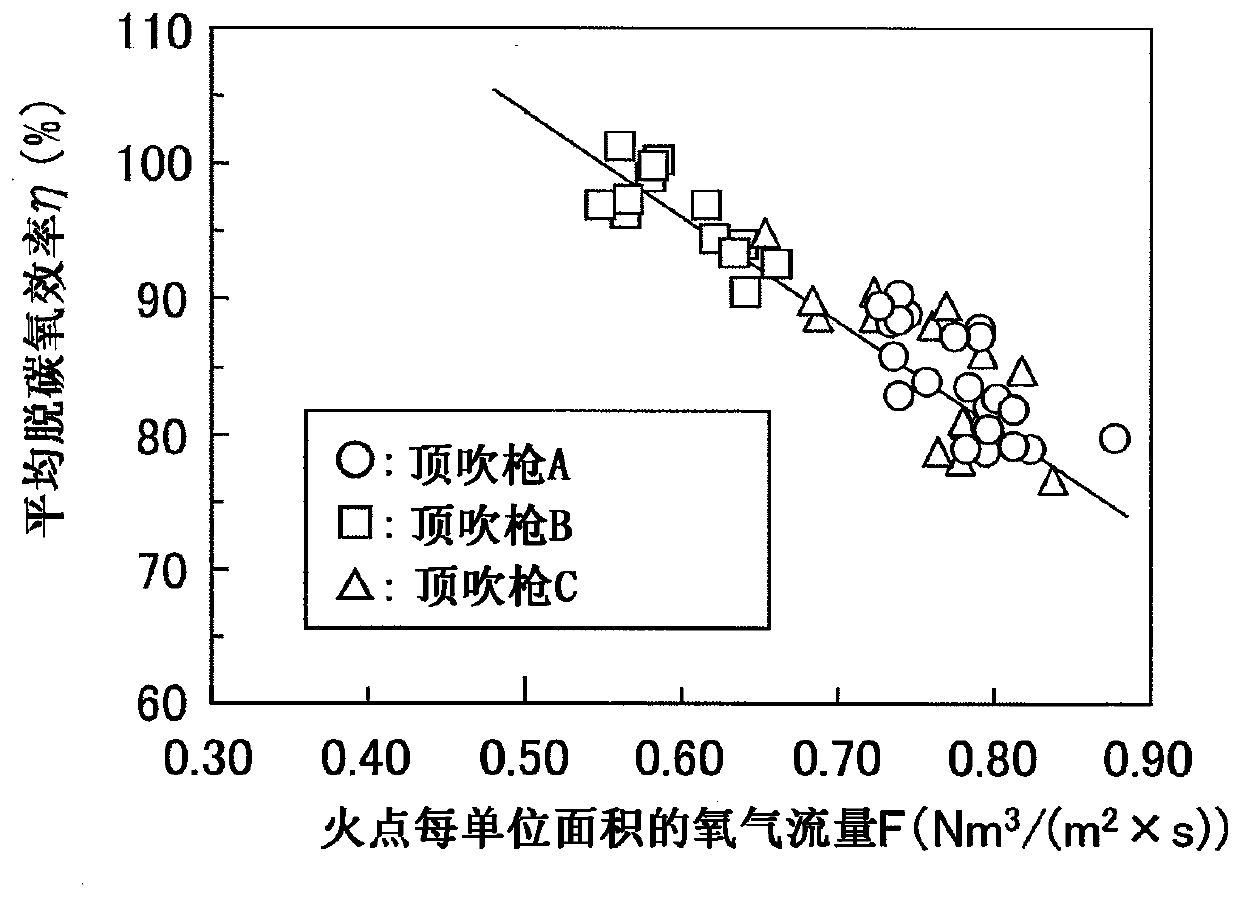

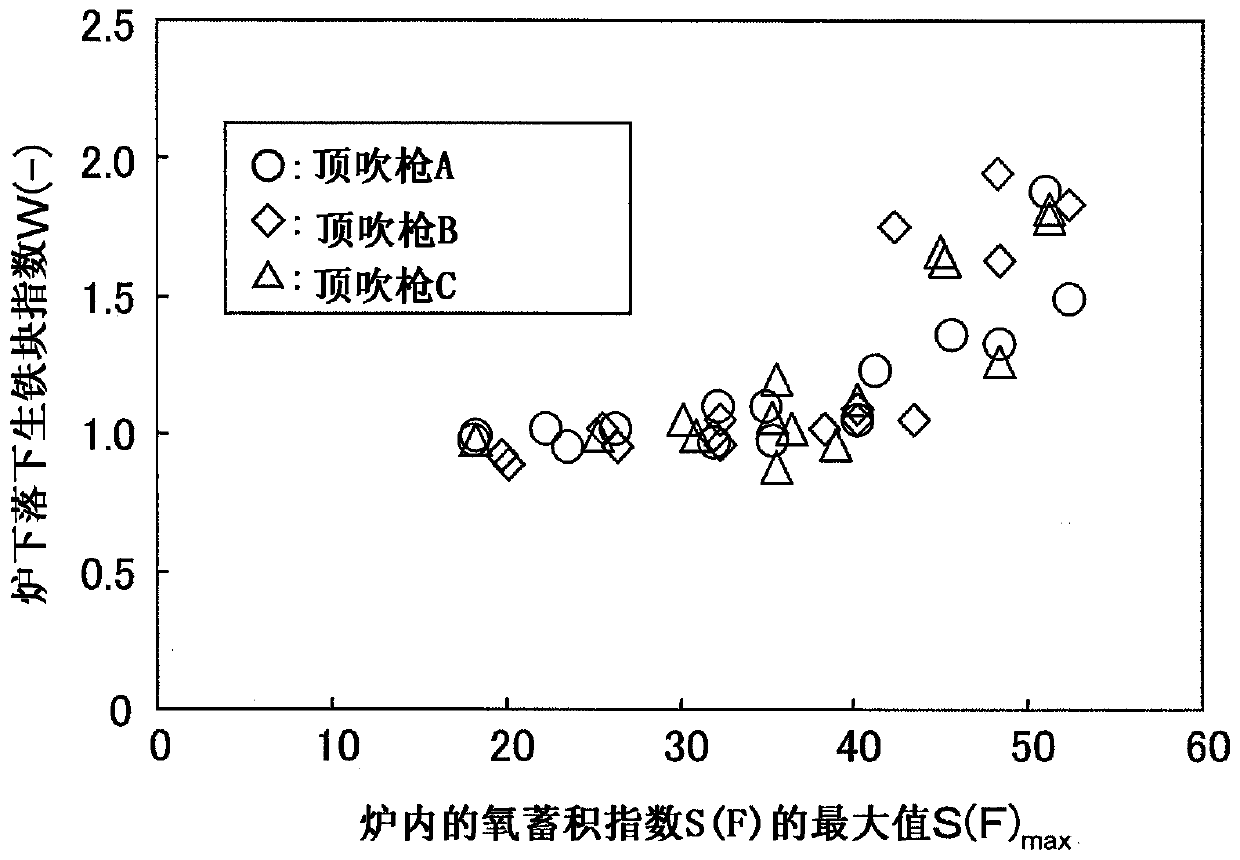

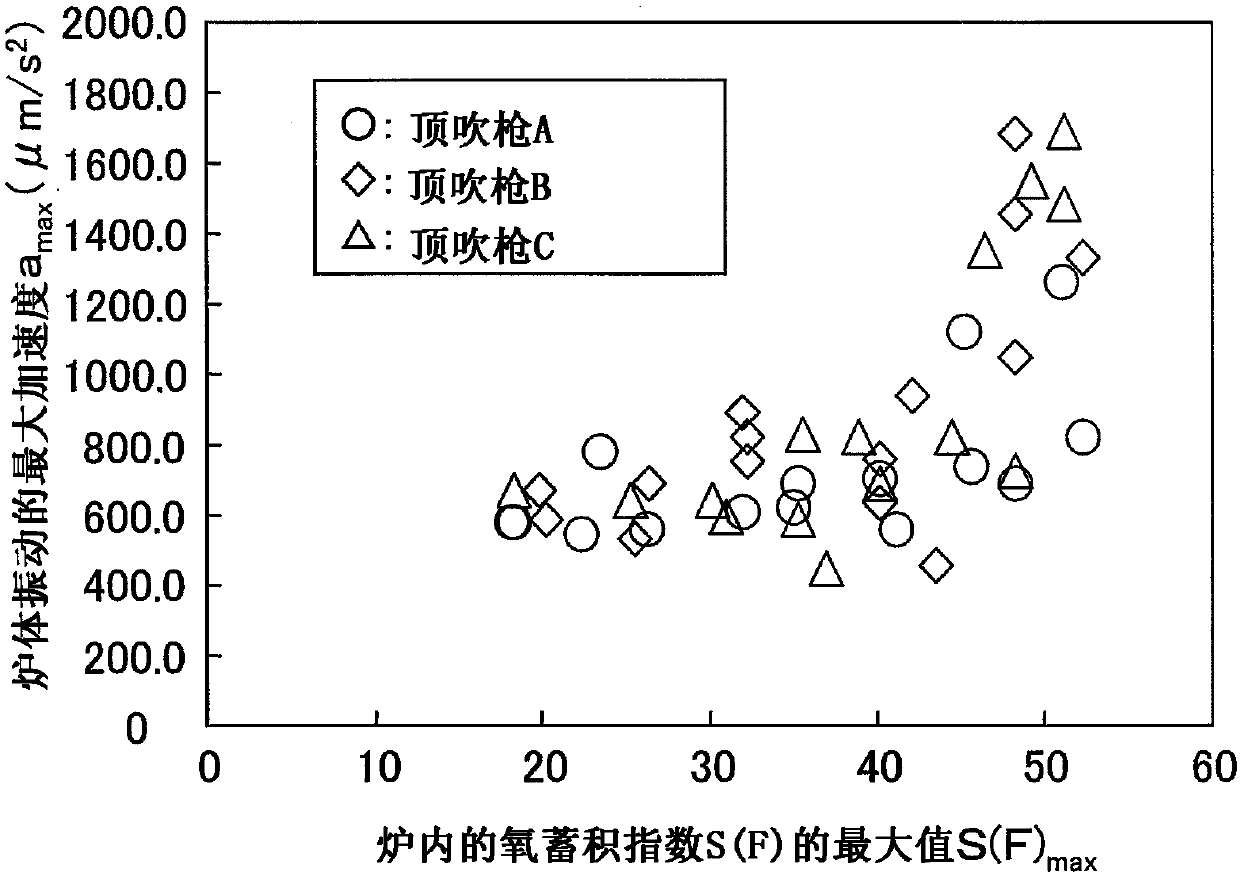

[0103] Next, examples of the present invention will be described. Decarburization blowing was carried out using a 300-ton capacity converter capable of blowing oxygen from a top-blowing lance and blowing stirring gas from bottom-blowing blade ports at the bottom of the furnace (hereinafter referred to as "top-bottom-blown converter"). As the evaluation of the escape of iron components to the outside of the furnace, the pig iron lump index W under the furnace defined by the formula (12) was used.

[0104] The top blowing gun used in this embodiment has 4 Laval nozzles of the same shape as injection nozzles at the front end, and the Laval nozzles are arranged at equal intervals on concentric circles with respect to the axis of the main body of the top blowing gun. The angle formed by the axis of the top blow gun body and the center axis of the nozzle (hereinafter referred to as "nozzle inclination angle") was arranged so that it was 17°. Laval nozzle throat diameter d c 76.0mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com