OCT guide pipe welding tool

A technology of welding tooling and conduits, which is applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems such as unestablished recommended grades, improve quality stability, ensure processing quality, and reduce human interference. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

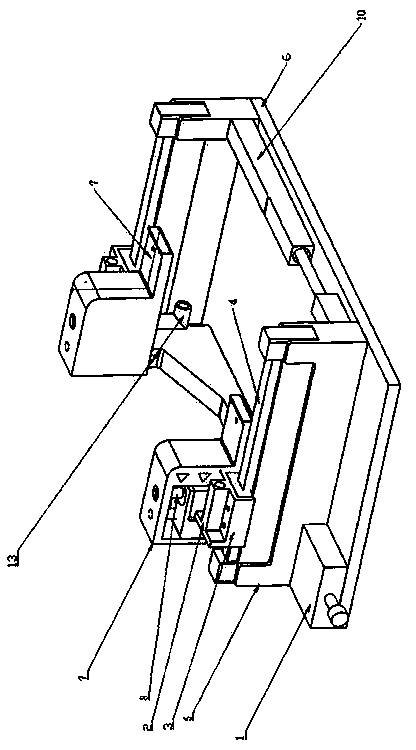

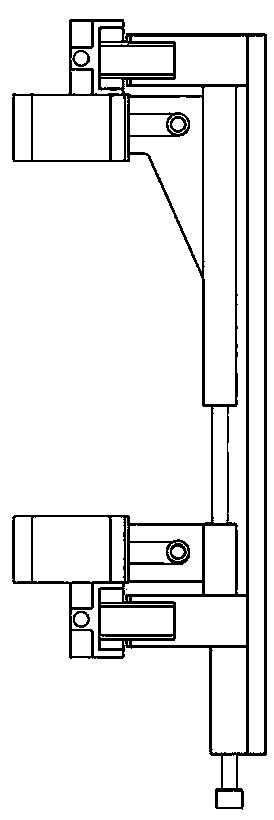

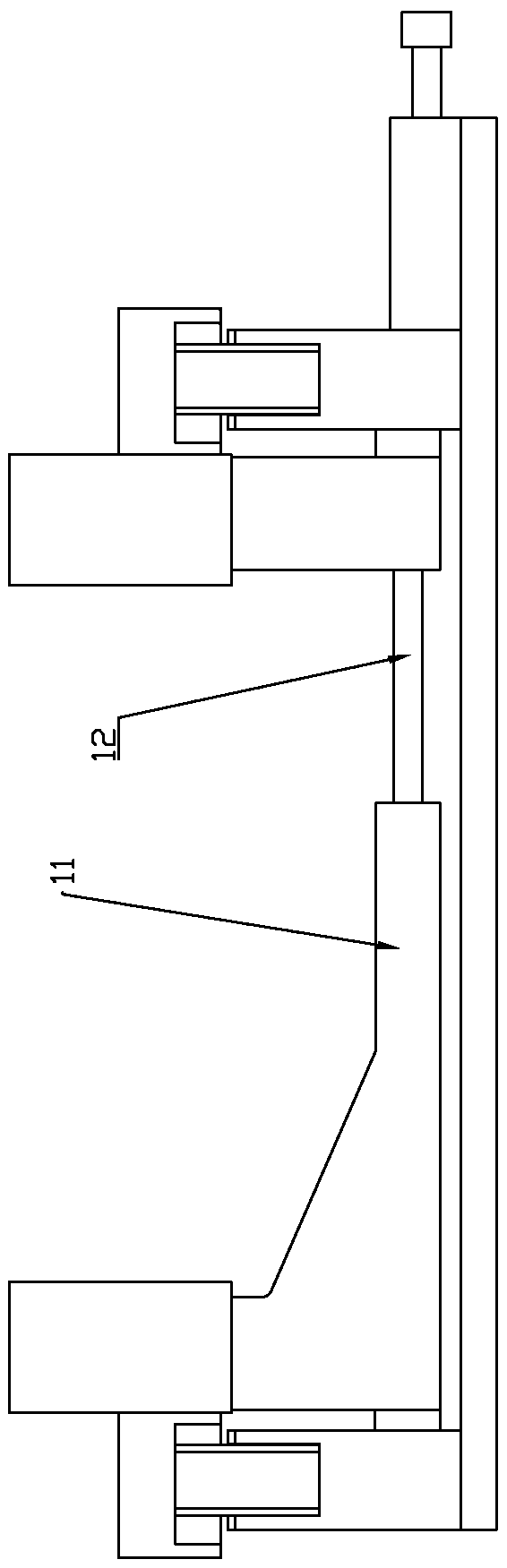

[0021] Such as Figure 1-4 shown.

[0022] An OCT catheter welding tool, the three-dimensional structure is as figure 1 As shown, the top view structure is as Figure 4 shown. It includes a base 6, and a linear guide rail fixing seat 5 is respectively installed at both ends of the base 6, wherein the linear guide rail fixing seat 5 at one end is fixed in the base 6, and the linear guide rail fixing seat 5 at the other end is connected with the displacement platform 1 and can be moved on The displacement platform 1 is driven to move towards the first linear guide rail fixing seat 5. The displacement platform 1 can adopt a hand-operated manual structure, an electric structure driven by a motor and a screw, or a pneumatic mechanism driven by a cylinder. One; the linear guide rail 4 is installed on the linear guide rail fixing seat 5, and the slide bloc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com