Furniture bamboo material joint removing method

A technology for bamboo and furniture, which is applied in the field of bamboo for furniture, and can solve the problems of affecting the flatness of the whole board, difficult to cut in place, cracking of the board body, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the objects and advantages of the present invention clearer, the present invention will be specifically described below in conjunction with examples. It should be understood that the following words are only used to describe one or several specific implementation modes of the present invention, and do not strictly limit the protection scope of the specific claims of the present invention.

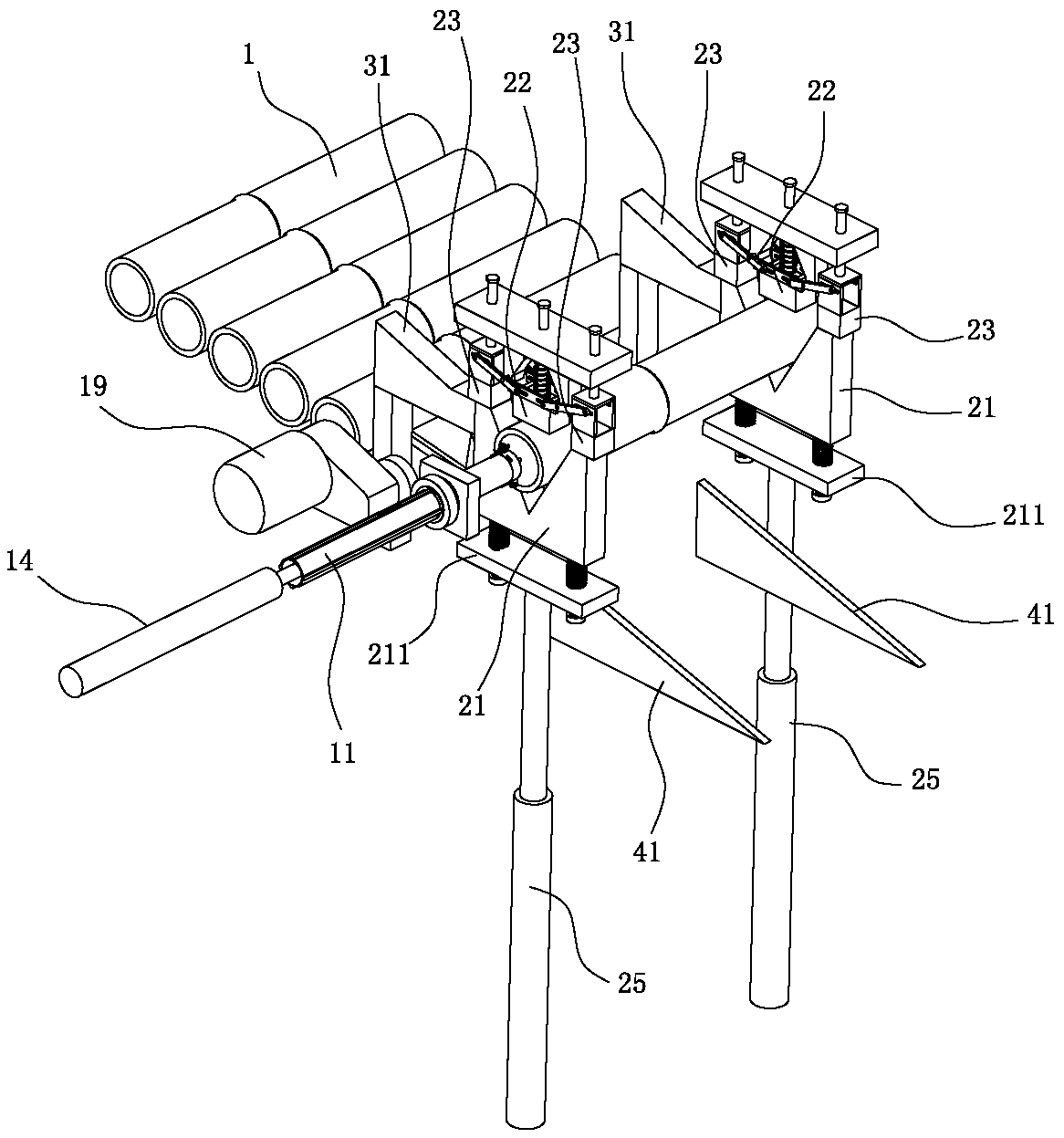

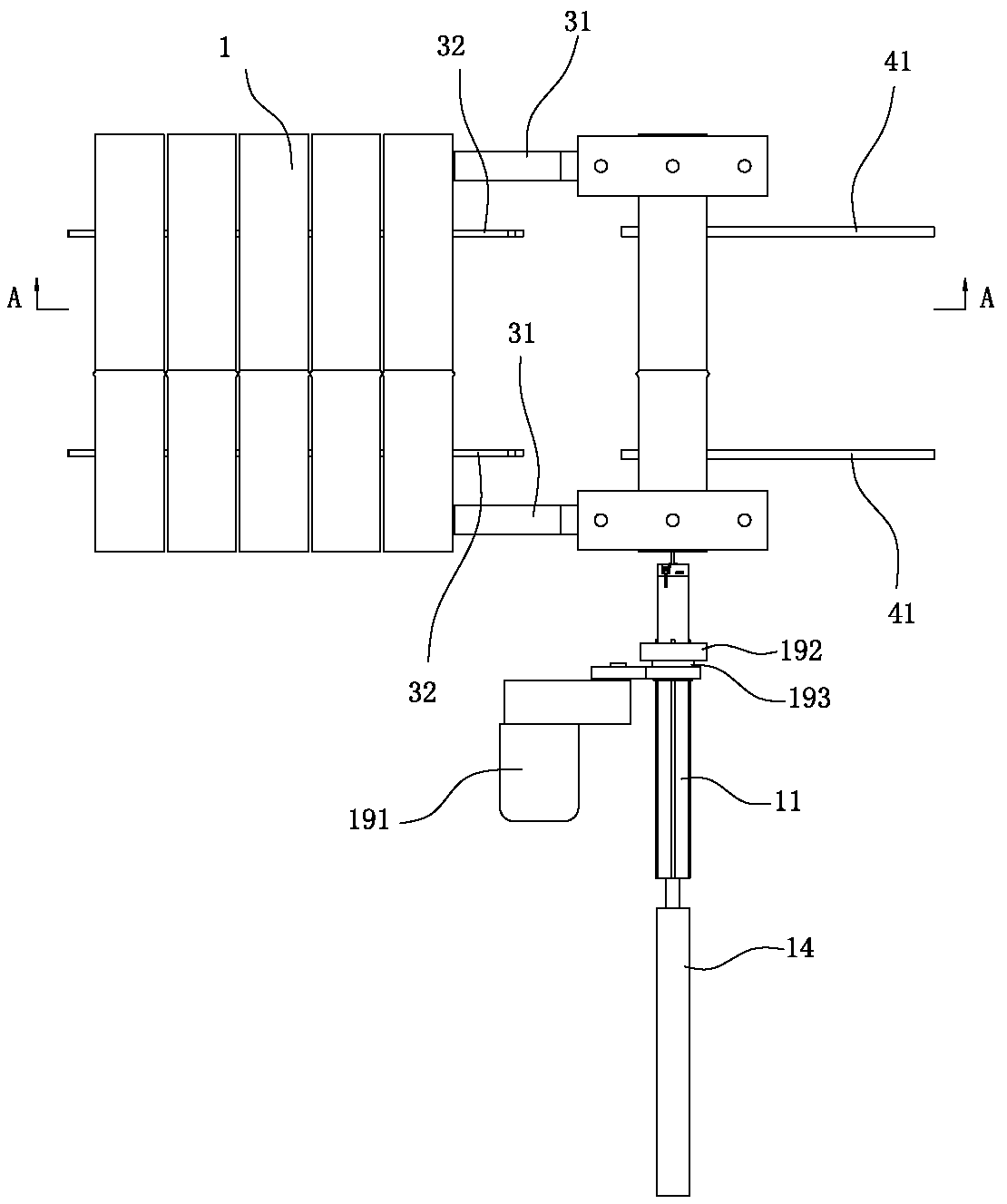

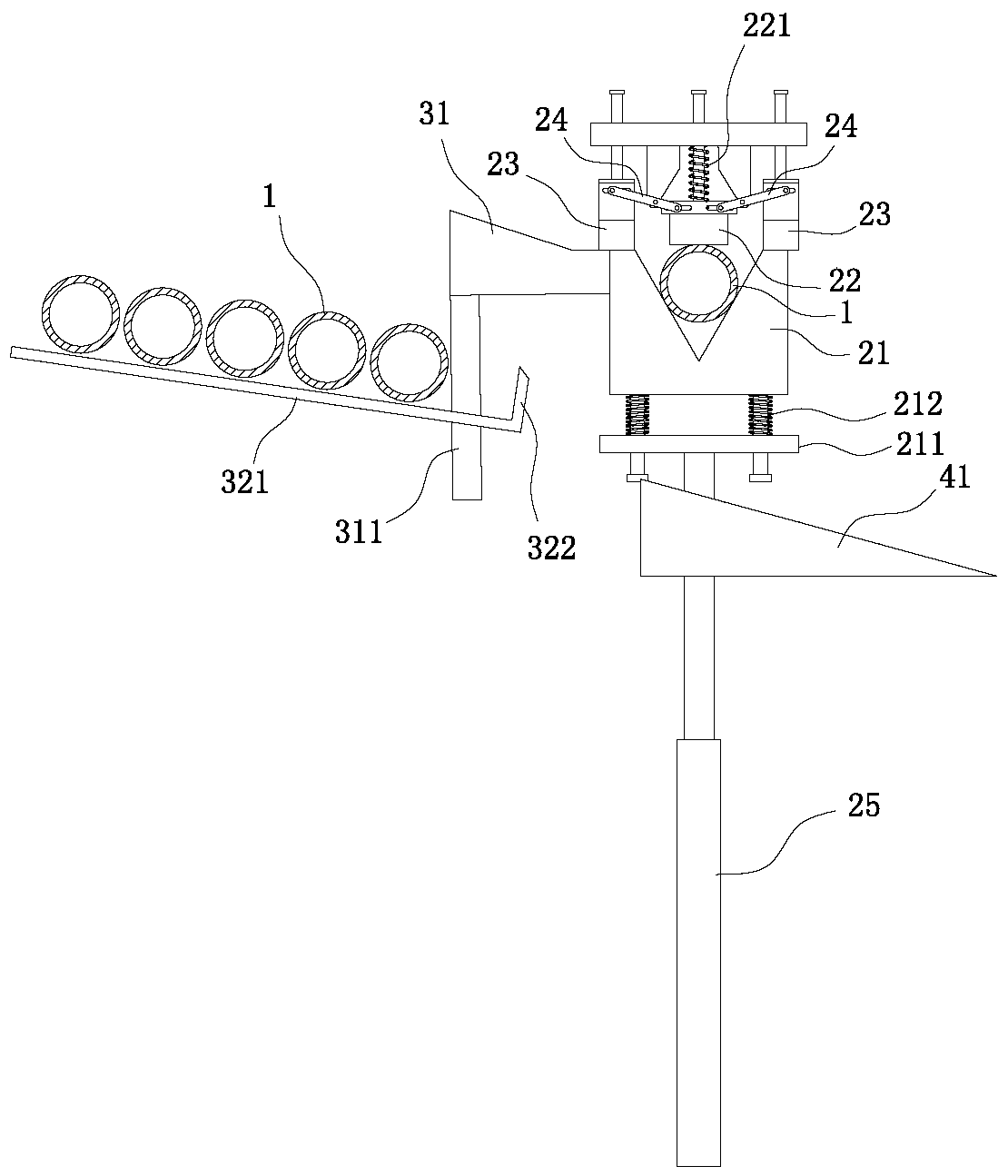

[0030] Such as figure 1 , 2 Said, a kind of bamboo processing device, comprises feeding mechanism and knuckle cutting tool system, and described feeding mechanism comprises importing mechanism, bamboo material centering mechanism and exporting mechanism; , and the axis of the bamboo 1 clamped by the bamboo centering mechanism is collinear with the axis of the cutter bar 11; as image 3 As shown, the bamboo centering mechanism includes a bracket 21 and a briquetting block 22, and the bracket 21 and the briquetting block 22 are all movably arranged on the frame along...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com