Automatic control method and automatic control device for air compressor, air compressor system and computer readable medium

An automatic control device and air compressor technology, which is applied in the direction of machines/engines, pump control, mechanical equipment, etc., can solve the problems that the pressure of the pipe network cannot be reliably guaranteed, and it is in the normal data range, so as to reduce production loss and control reliability high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

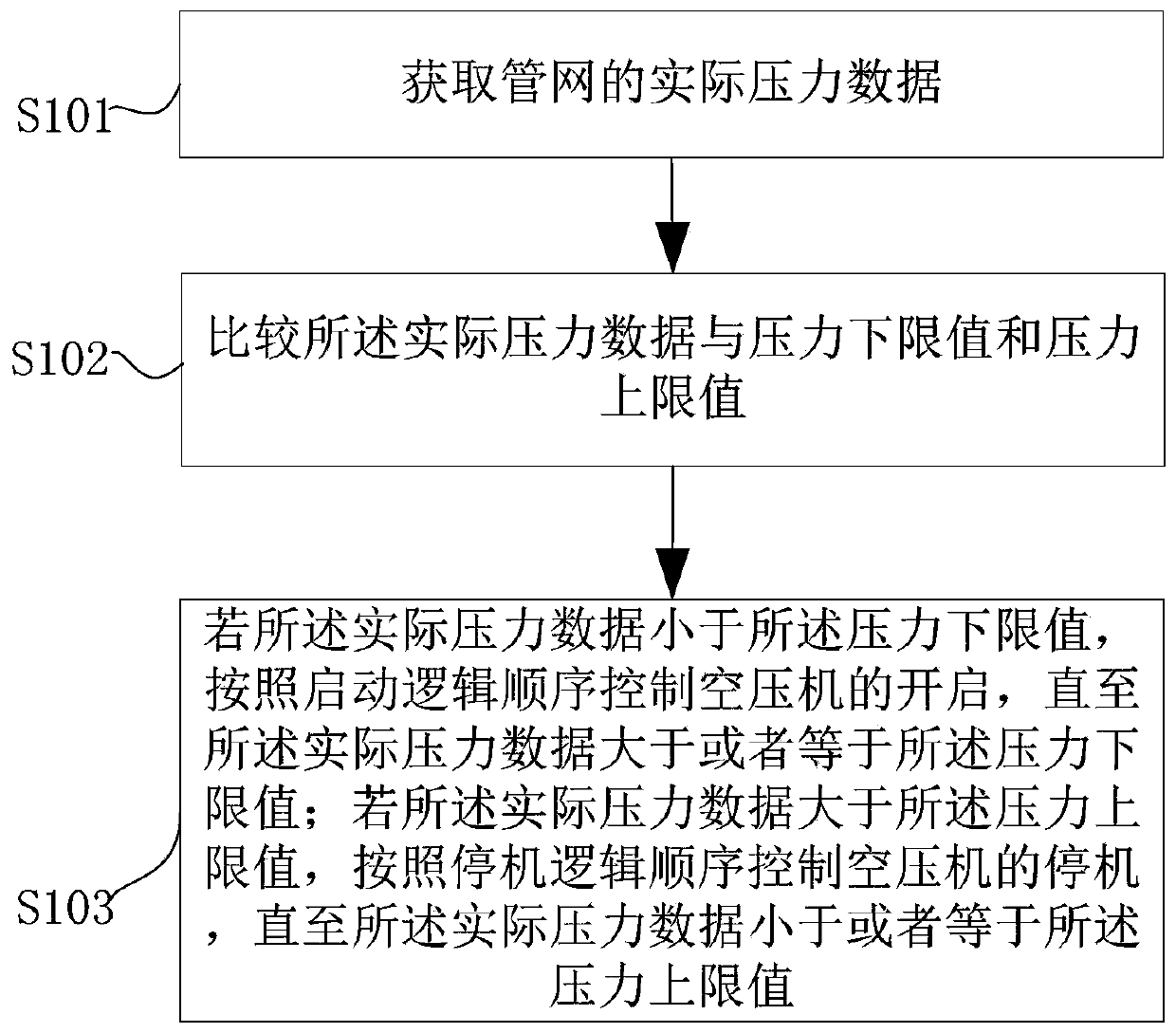

[0036]If the actual pressure data of the pipe network is less than the lower pressure limit, it means that the pressure of the pipe network is too low, and it is necessary to increase the pressure of the pipe network to make it within the normal value range. Since the number of air compressors is closely related to the pressure of the pipe network, the more air compressors are used, the more compressed air is injected into the pipe network, and the pressure of the pipe network will be greater. Therefore, if the actual pressure data of the pipe network is less than the lower pressure limit, the start-up logic sequence is used to control the opening of the air compressors, that is, to increase the number of air compressors, and to control the input of a part of the air compressors from the stopped air compressors. (Installing the air compressor is to start the air compressor), the number of input air compressors increases, and the pressure of the pipe network will increase. A sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com