Resistance test system for real sea large-scale ship model

A resistance test, large-scale technology, applied in the field of ship hydrodynamic experiments, can solve the problems affecting the resistance measurement accuracy, heavy weight, and length of the pull rope, and achieve the effect of improving the measurement accuracy, ensuring the heading stability, and improving the stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the embodiments and the accompanying drawings, but the embodiments of the present invention are not limited thereto.

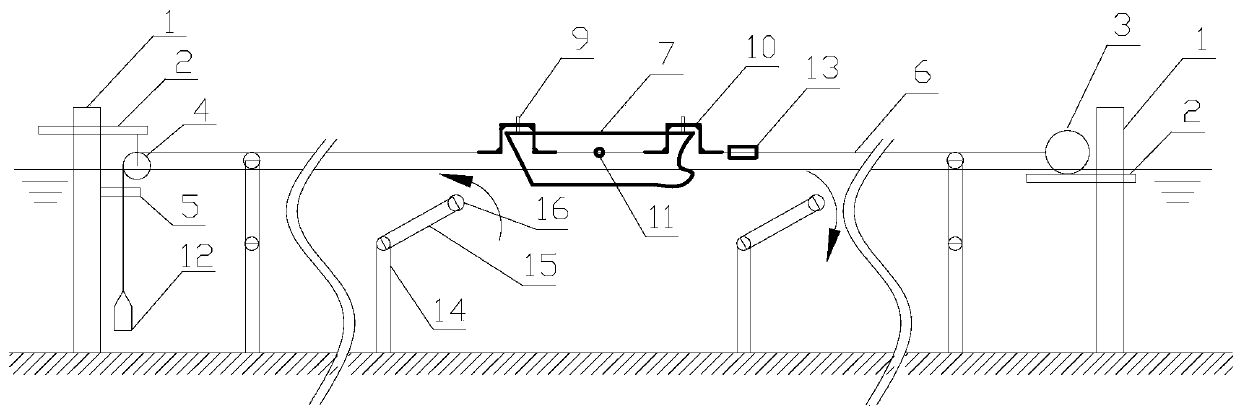

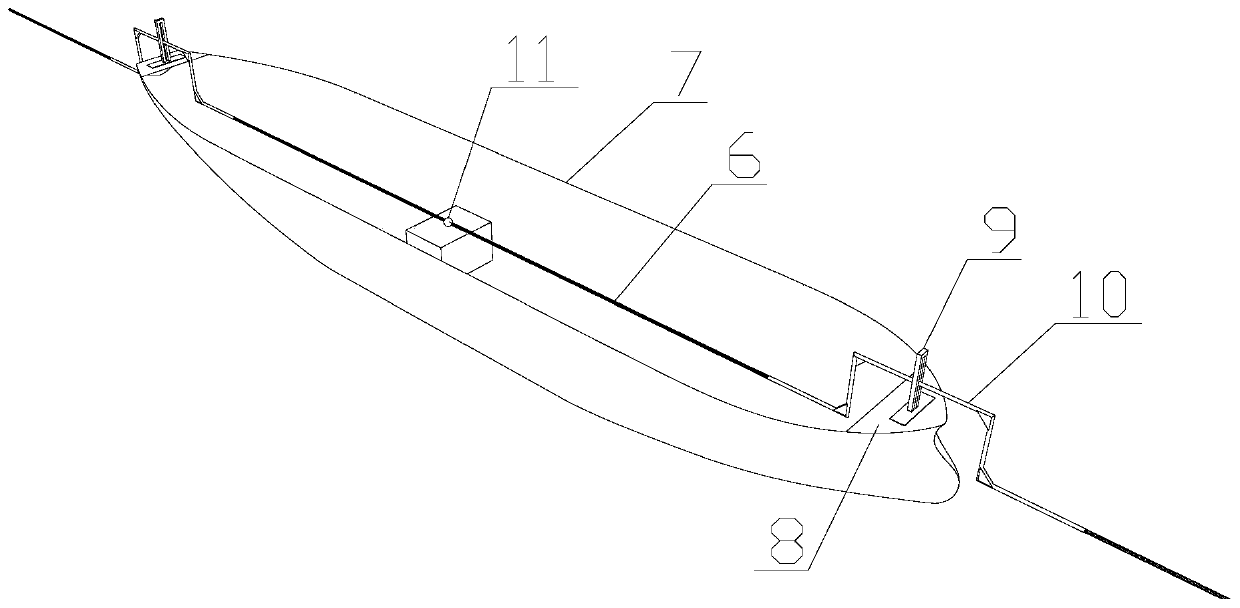

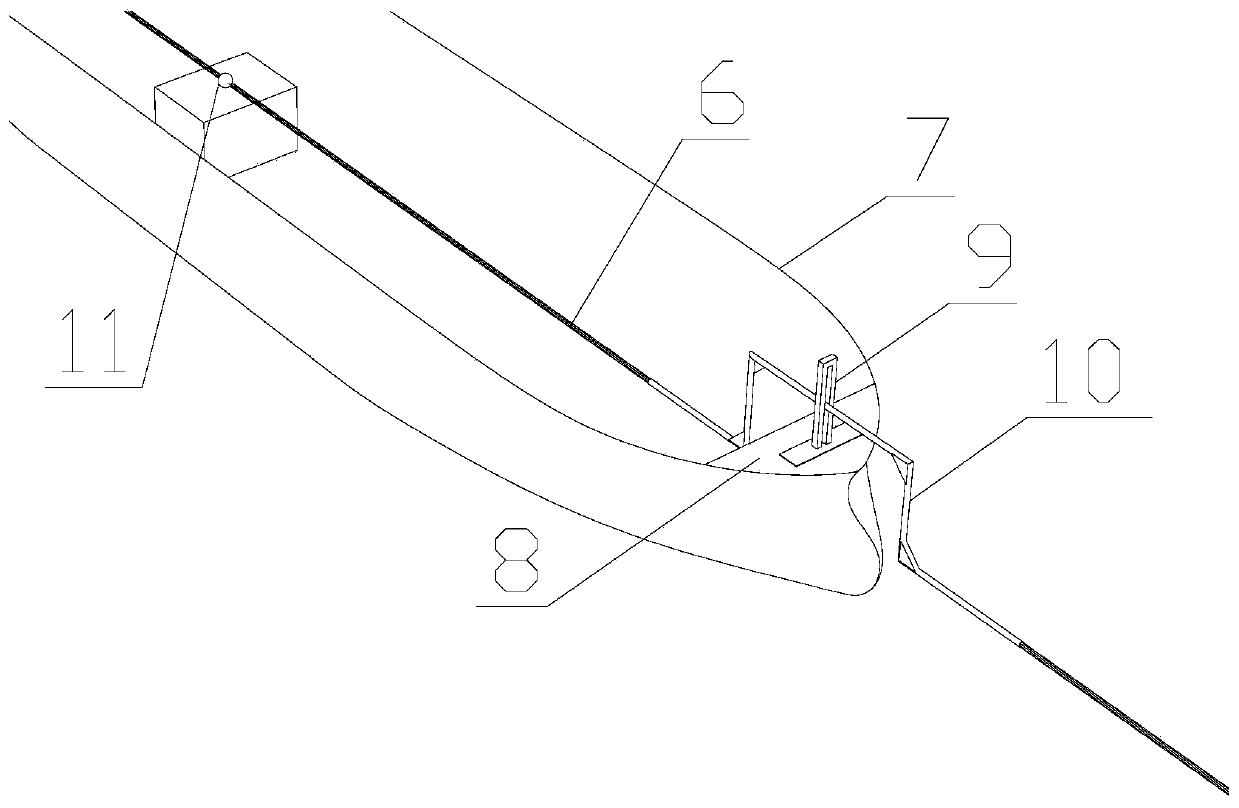

[0030] A large-scale ship model resistance test system in actual sea area includes a reference platform system, a ship model system, a tow system, a tow rope support system, and a control and measurement system.

[0031] The reference platform system includes two reference platforms fixed on the seabed. The reference platform can be a pile or a wharf fixed on the seabed. The two reference platforms are respectively fixed in the middle longitudinal plane in front of the ship model and behind the ship model. The front of the ship model refers to the direction of the bow, and the rear of the ship model refers to the direction of the stern. Both reference platforms are provided with lifting bases that can move vertically along the platform and be locked. A buoyancy material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com