Manufacturing method of metal nanowire or sheet and nanowire or sheet

A metal nanowire and a manufacturing method technology, applied in the manufacture of metal nanowires or sheets, in the field of nanowires or sheets, can solve problems such as difficult etching, inability to flexibly control the width and thickness of nanowires, uncontrollable cross-sectional shape of nanowires, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

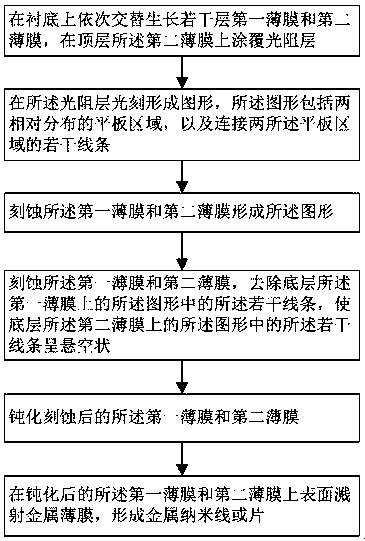

[0051] see Figure 1-Figure 4 , Figure 5A-Figure 9A , Figure 5B-Figure 9B and Figure 10 , the method includes:

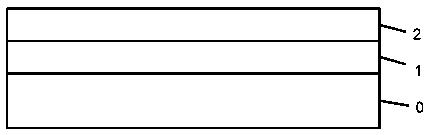

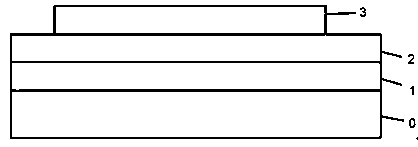

[0052] S101 : growing a first film 1 and a second film 2 sequentially on a substrate 0 , and coating a photoresist layer 3 on the second film 2 .

[0053] In the field of semiconductors, the substrate 0 may be understood as a base for forming transistors or other semiconductor devices thereon. On the one hand, the substrate 0 acts as a mechanical support, and a thin film is formed on the substrate 0 by physical or chemical means, and then semiconductor devices are formed by processes such as photolithography and atom implantation. On the other hand, the substrate 0 has the effect of improving the film properties. The film is formed on the substrate 0. The material properties of the substrate 0 and the surface shape of the substrate 0 have a great influence on the film properties. Since the film thickness is usually in the nanometer Between micron and micron,...

Embodiment 2

[0068] see figure 1 , Figure 11-Figure 18 , Figure 19A-Figure 22A , Figure 19B-Figure 22B and Figure 23 , the method includes:

[0069] S201: growing two layers of the first thin film 1 and the second thin film 2 alternately in sequence on the substrate 0, and coating the photoresist layer 3 on the second layer of the second thin film 2.

[0070] It should be noted that, in this embodiment, the first layer of the first thin film 1, the first layer of the second thin film 2, the second layer of the first thin film 1, and the second layer of the second thin film 2 are sequentially grown upward on the substrate 0 (see Figure 11 ), can also alternately grow three layers, four layers, etc. In this embodiment, chemical vapor deposition (CVD) is used for film growth. The first film 1 is SiO2 with a thickness of 50 nanometers, and the second film 2 is an amorphous Si film with a thickness of 100 nanometers.

[0071] After growing the first layer of the first thin film 1, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com