Manufacturing method of trench and manufacturing method of memory device

A manufacturing method and storage device technology, applied in the field of memory manufacturing and groove manufacturing, can solve problems such as the difficulty of critical dimensions of U-shaped grooves, increase effective current and read window, reduce channel length, Effects that improve resolution and fidelity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] For reference and clarity, descriptions, abbreviations or abbreviations of technical terms used hereinafter are summarized as follows:

[0050] BARC: Bottom Anti Reflection Coating;

[0051] DARC: Dielectric Anti Reflective Coating, dielectric anti-reflection coating;

[0052] ODL: Organic Dielectric Layer, organic underlying structure layer;

[0053] SHB: Si-O-based Hard Mask, silicon oxide hard mask interlayer structure layer.

[0054] As described in the background art, it is difficult to further reduce the critical dimension (CD) of the U-shaped trench in the existing semi-floating gate transistor fabrication process.

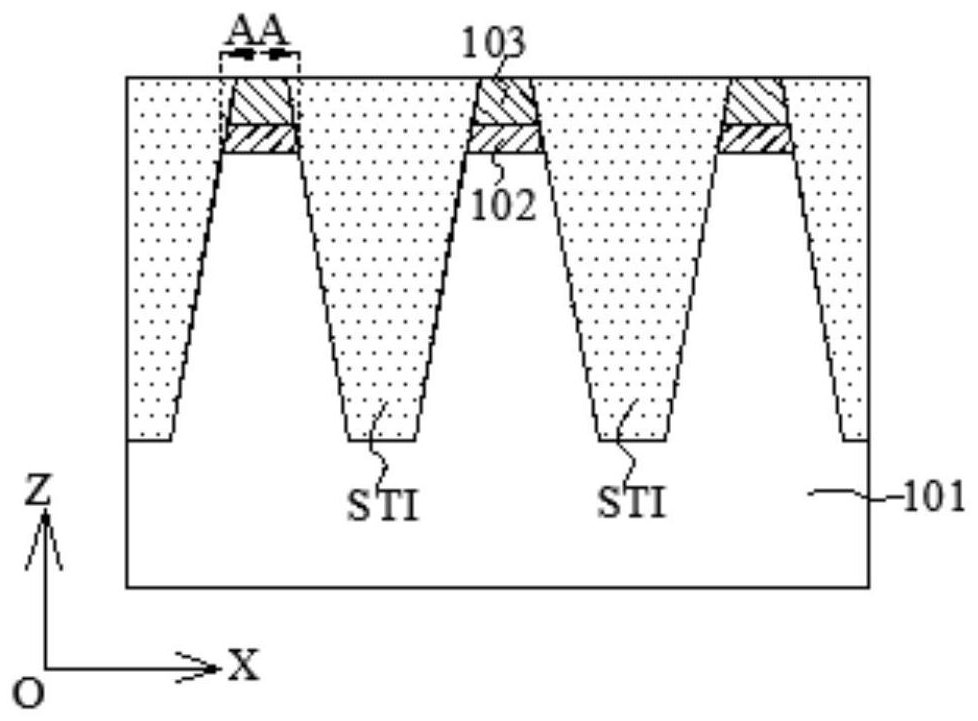

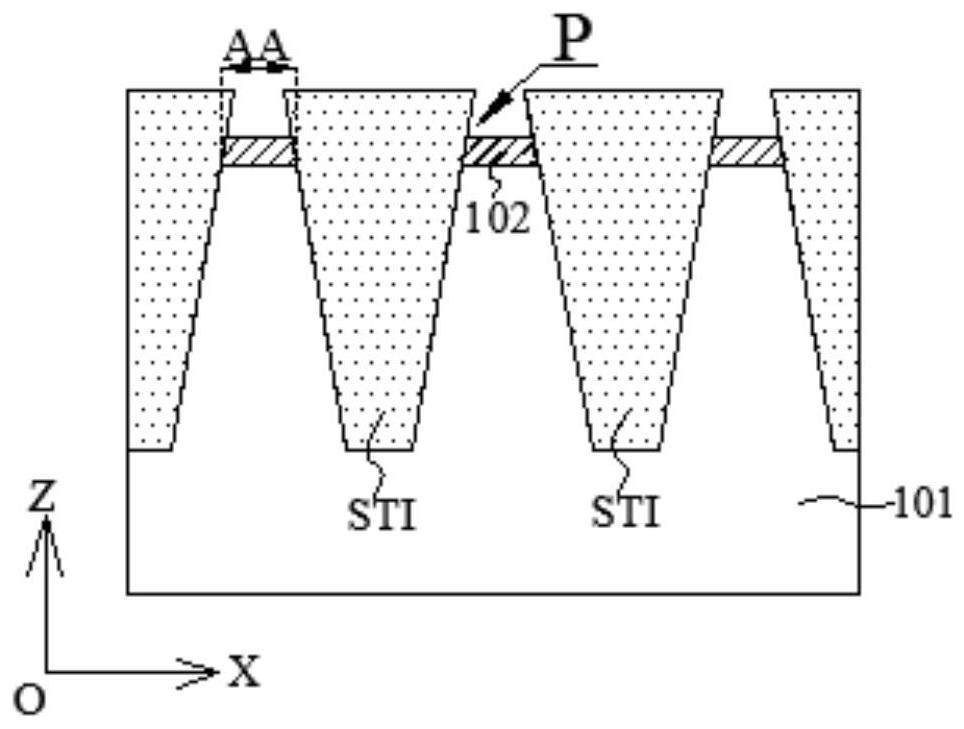

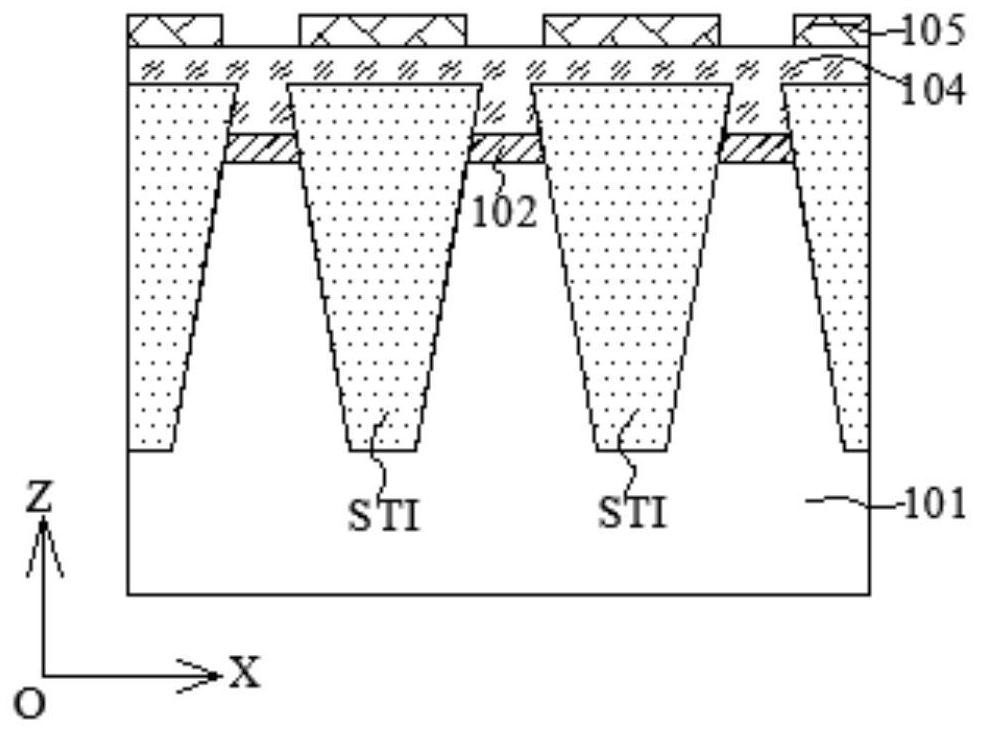

[0055] Specifically, an existing manufacturing process for a semi-floating gate transistor includes the following steps: Figure 1 to Figure 4 steps in .

[0056] like figure 1 As shown, a silicon oxide layer 102 and a silicon nitride layer 103 are sequentially formed on the substrate 101, and shallow trench isolation STIs are formed at interval...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com