Heat dissipation bottom plate, heat dissipation element and preparation method thereof, and igbt module

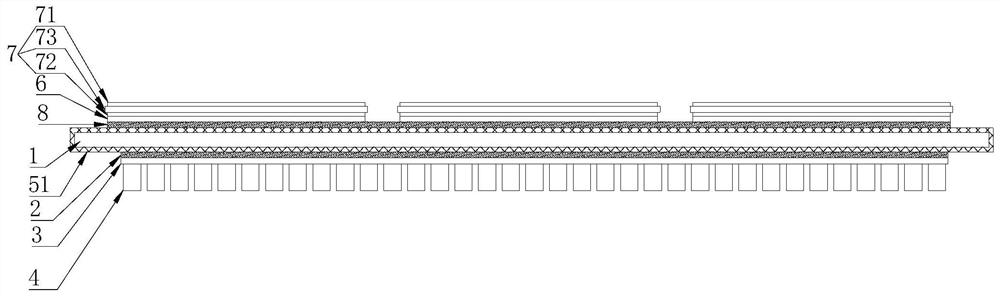

A technology of heat dissipation base plate and heat dissipation element, which is applied in the direction of electrical components, semiconductor devices, electric solid devices, etc., can solve the problems of limiting the efficiency of cooling liquid contact heat dissipation, high mold friction, and high mold cost, so as to improve heat dissipation performance and thermal expansion. The coefficient is suitable and the effect of improving the binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

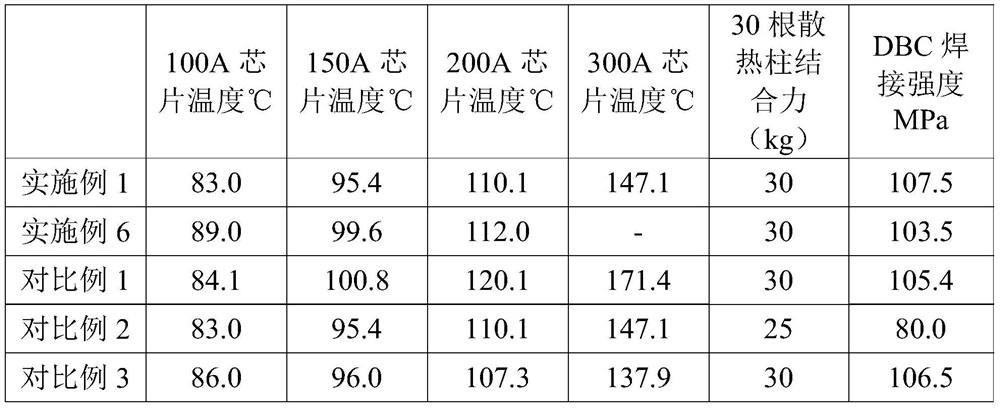

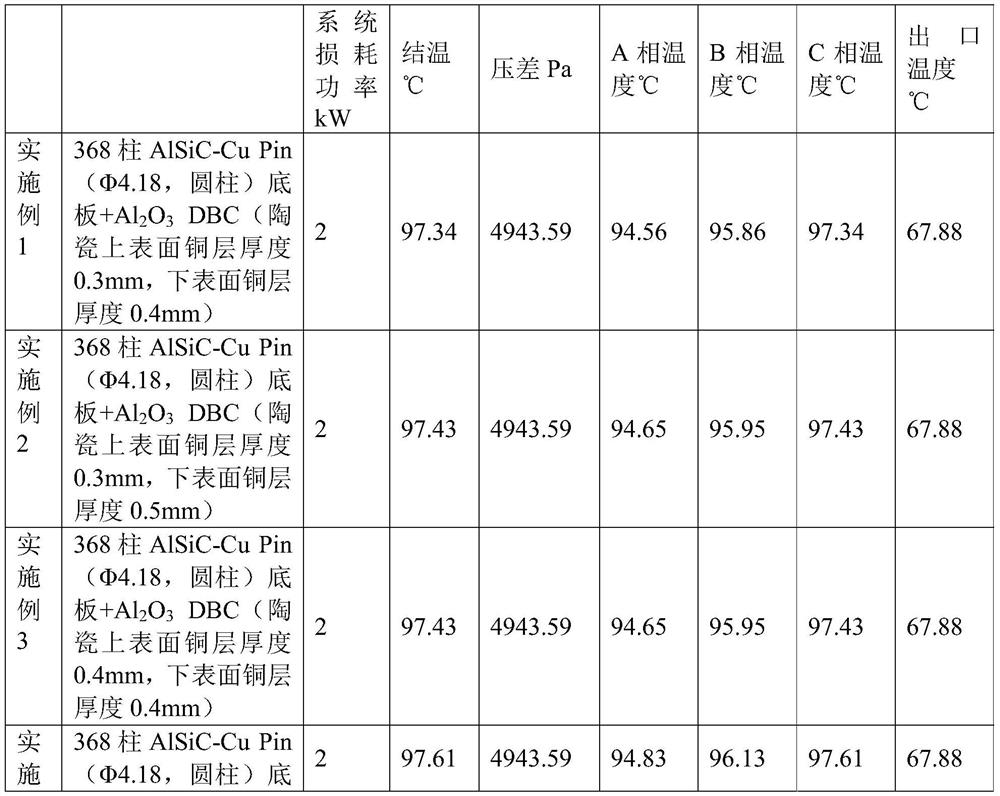

Embodiment 1

[0082] This embodiment is used to illustrate the heat dissipation bottom plate of the present disclosure and its preparation method. Including the following steps:

[0083] 1. Air-casting and infiltration forming AlSiC board: adopt air-pressure infiltration bin equipment, preheat the SiC substrate to 500-700°C, pour aluminum, vacuumize (remove gas, prevent product from producing pores), and fill with nitrogen Pressurize (4-10MPa, to promote the aluminum liquid to fill the mold evenly) and cool down to obtain an AlSiC plate;

[0084] 2. Nickel-plate the surface of the AlSiC plate, and the thickness of the nickel layer is 12 μm;

[0085] 3. Cold spray copper on the first main surface of the AlSiC plate with nickel plating to form the first copper spray layer with a thickness of 100 μm; cold spray copper on the second main surface to form the second copper ceramic substrate area. Copper spray layer, thickness 100μm

[0086] 4. Surface cleaning of heat dissipation column: Metal...

Embodiment 2~5

[0090] Using the method and materials of Example 1, the difference is that Al 2 o 3 The thickness of the copper layer on both sides of the DBC is different, see Table 2 for details.

Embodiment 6

[0092] The method and materials of Example 1 are used, except that an AlN copper-clad ceramic substrate is used.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com