Stirring device for solder paste for producing computer motherboard

A technology of a computer motherboard and a stirring device, which is applied in the computer field, can solve the problems of decreased work efficiency, dust entry, uneven stirring, etc., and achieves the effect of ensuring airtightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

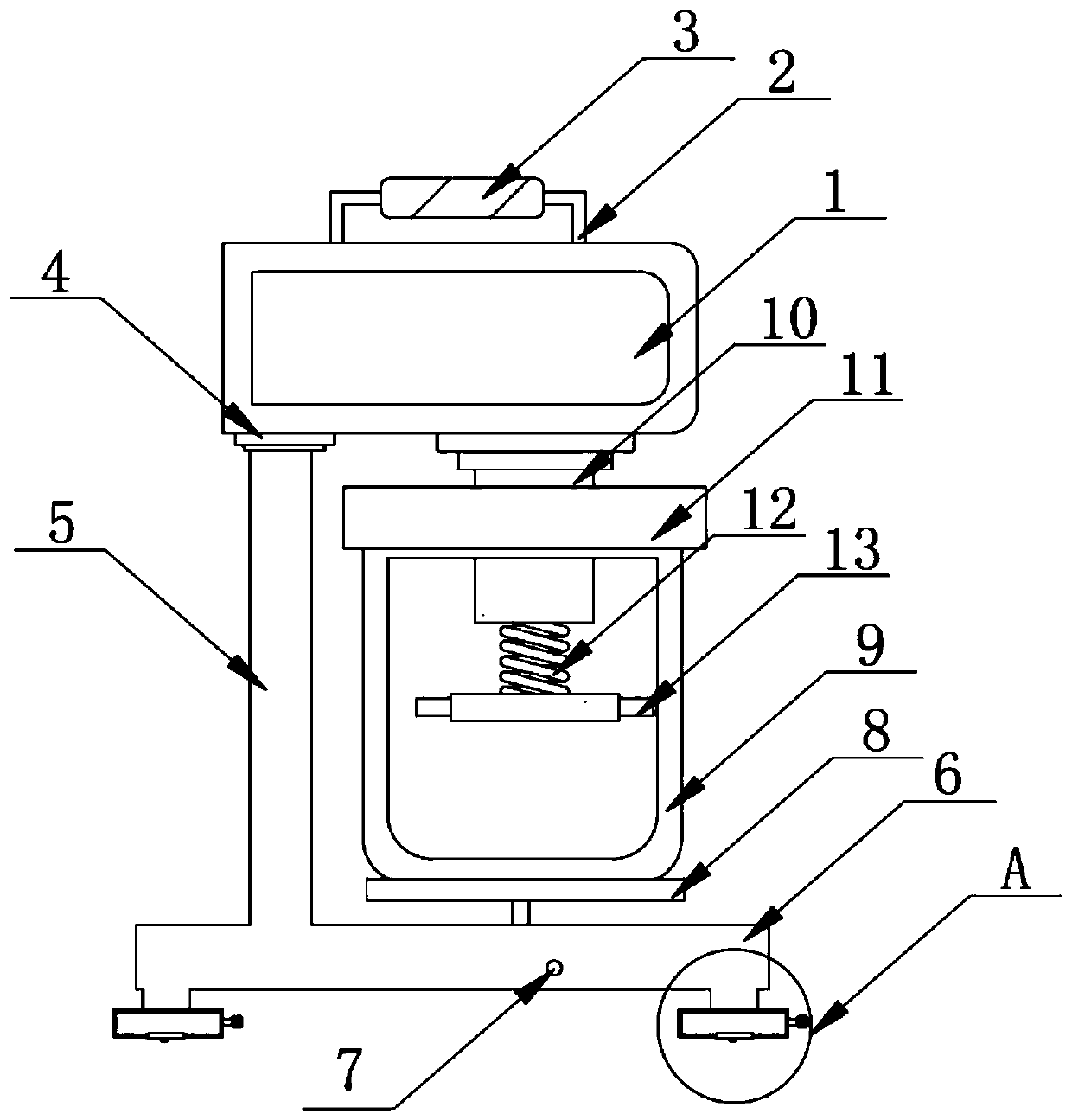

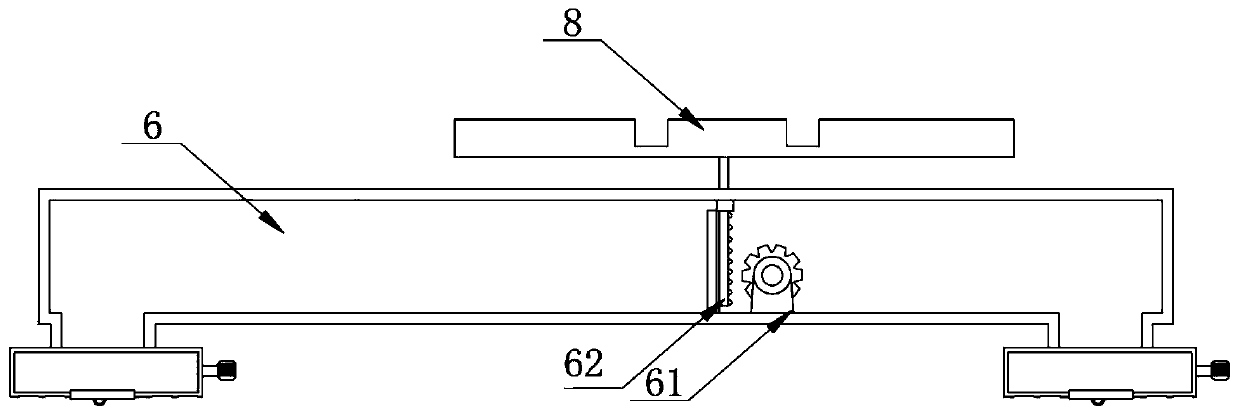

[0030] as attached Figure 1-8 The drive motor 1 shown is included, the top of the drive motor 1 is fixedly installed with a tie rod 2, the middle part of the pull rod 2 is fixedly installed with an anti-skid block 3, the left bottom of the drive motor 1 is fixedly installed with a fixed block 4, and the bottom of the fixed block 4 is fixed. Support bar 5 is installed, and the bottom of support bar 5 is fixedly installed with bottom support bar 6, and the middle part of bottom support bar 6 is movably installed with adjusting buckle 7, and the top of bottom support bar 6 is fixedly connected with movable plate 8, and the top of movable plate 8 The carrier 9 is inlaid and installed, and the left bottom of the driving motor 1 is disassembled and installed with a rotating shaft 10. The bottom of the rotating shaft 10 is movably connected with a sealing plate 11, and the bottom of the rotating shaft 10 is fixedly connected with a spring 12. The bottom of the spring 12 is fixedly co...

Embodiment 2

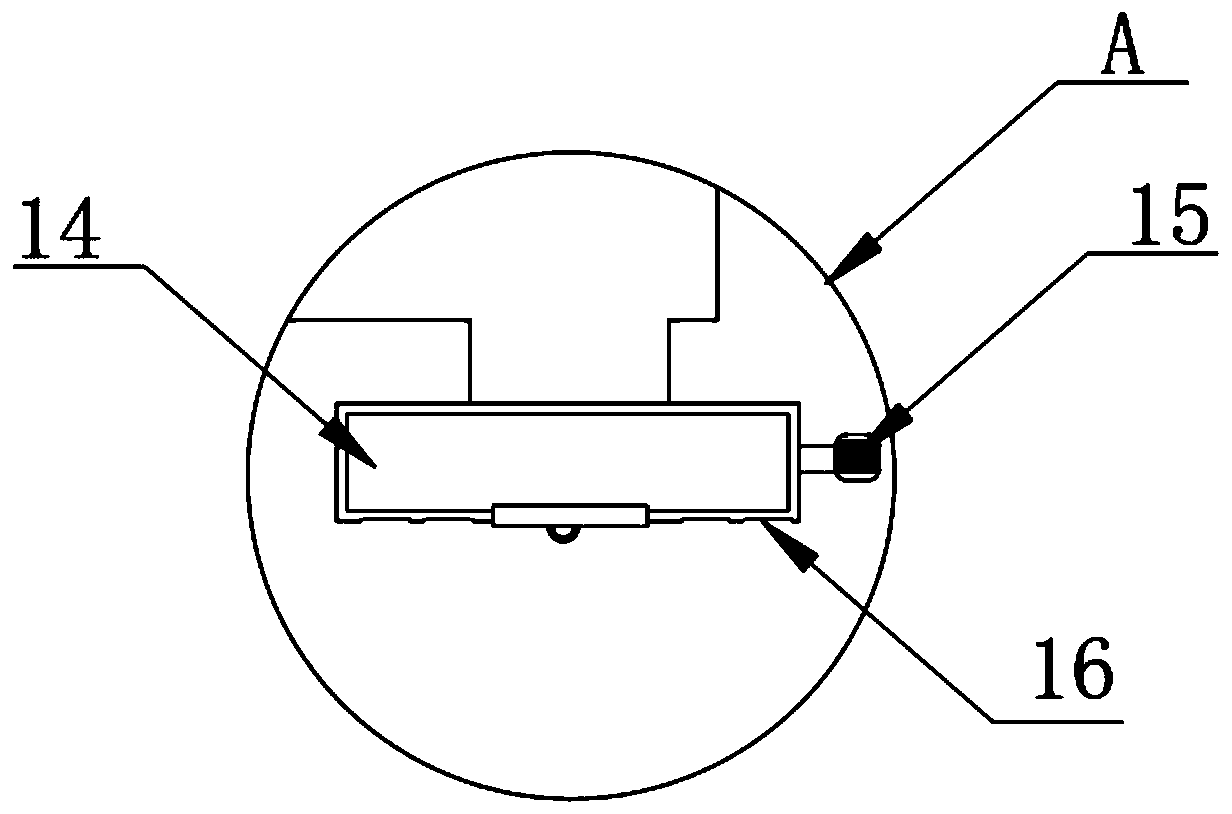

[0044] Specifically compared with Embodiment 1: the bottom of the movable block 14 is provided with a groove 16, and rubber blocks are fixedly installed inside the groove 16, and the number of rubber blocks and the number of grooves are several.

[0045] Using the above means: by fixing the rubber block inside the groove 16, the contact area with the ground can be increased, the friction force can be enhanced, and the damage to the machine can be reduced by the rubber block

[0046] working principle:

[0047] The first step: firstly install the parts of each part, and then put the solder paste into the inside of the carrier 9. At this time, using the carrier 9, the fixed block 92 fixedly installed at the bottom and the fixed groove 81 opened on the surface of the movable plate 8 are engaged. Then turn the gear 61 to the right, and because the left side of the gear 61 is meshed with the straight tooth 62, the straight tooth 62 moves upwards, so that the carrier 9 mounted on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com