Waste glass bottle recycling and regenerating production line and processing method

A glass bottle and production line technology, applied in chemical instruments and methods, solid waste removal, transportation and packaging, etc., can solve problems such as waste of resources, physical injury of staff, pollution of the environment, etc., to improve work efficiency and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

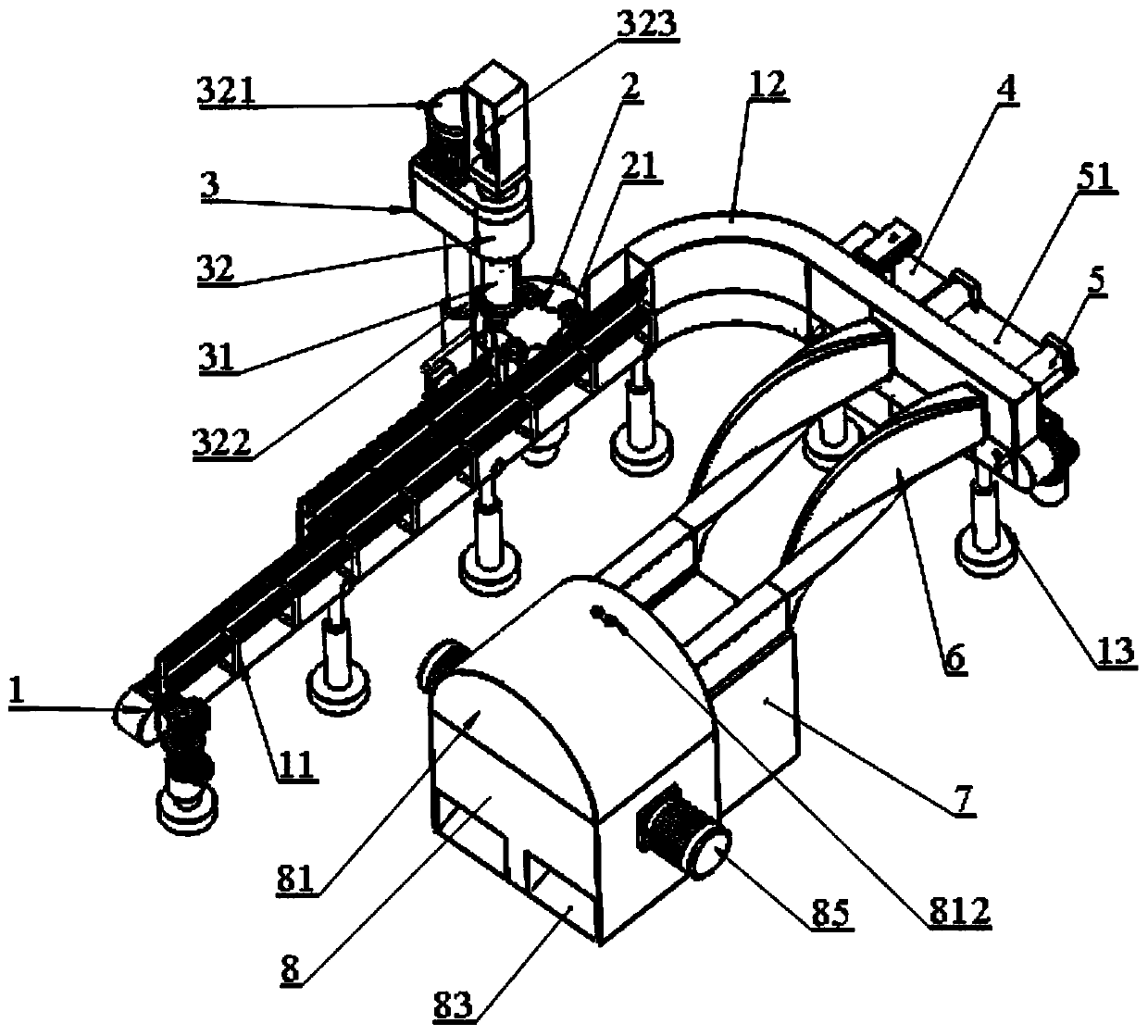

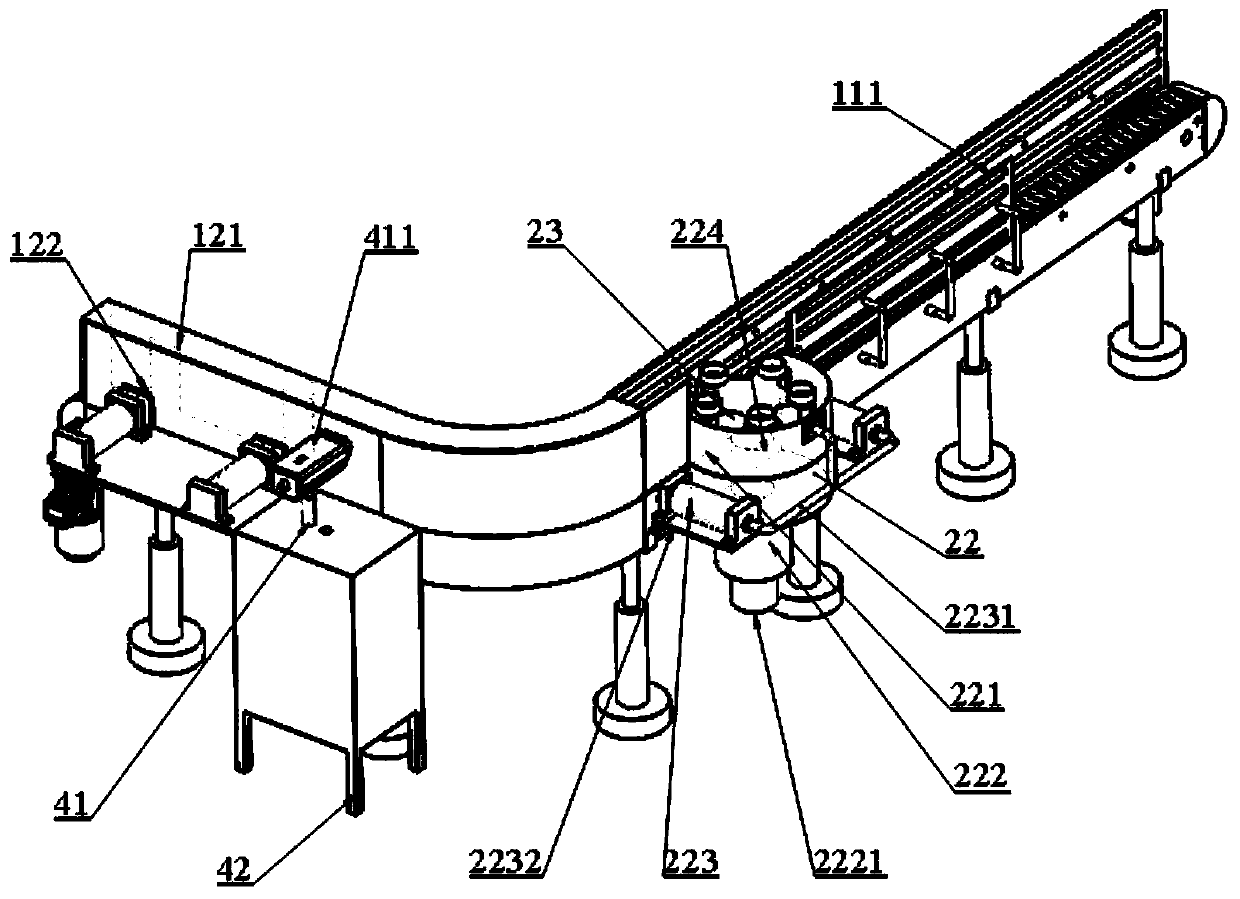

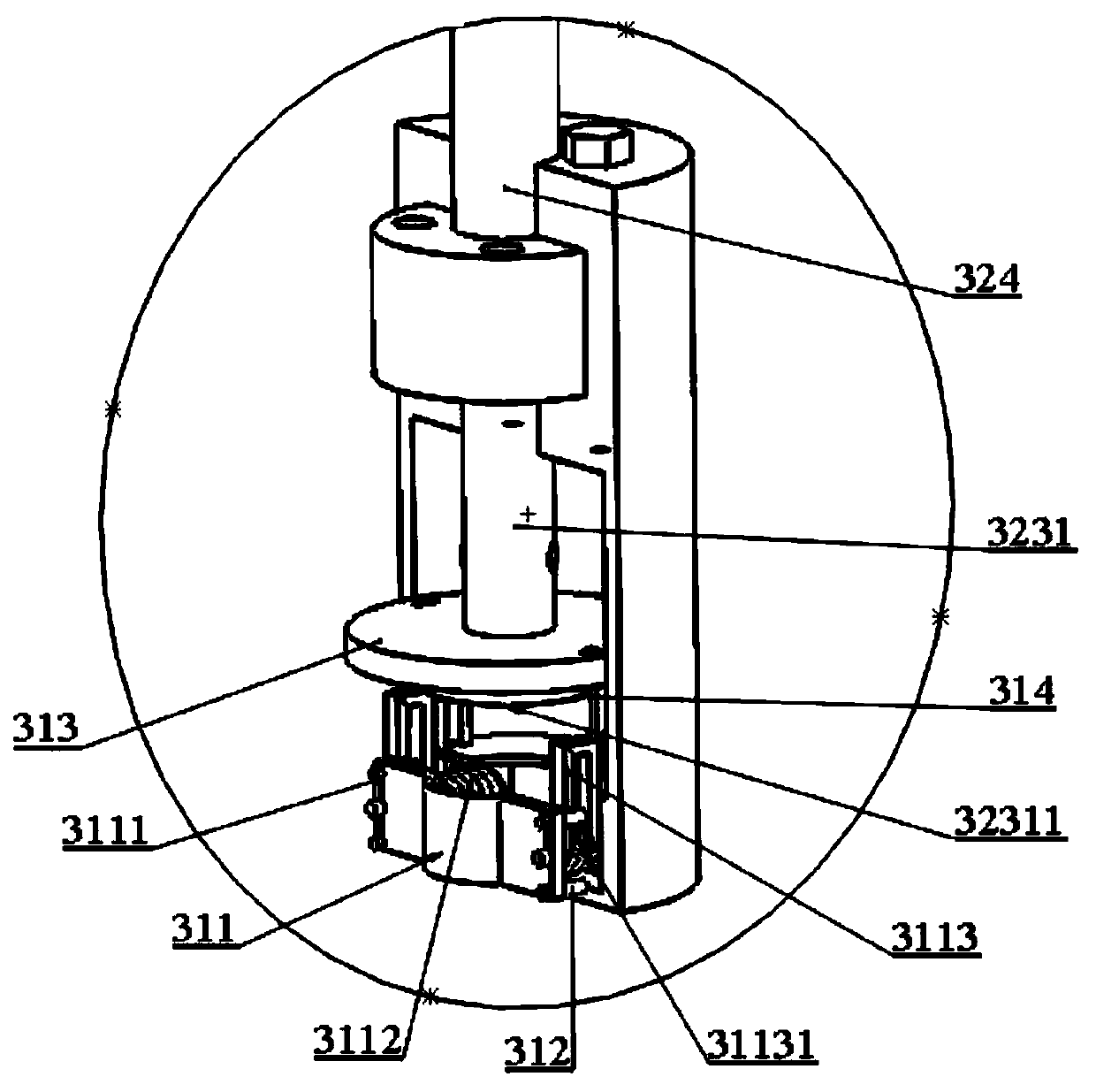

[0020] The waste glass bottle recycling production line of the present invention will be further described in detail in conjunction with the accompanying drawings.

[0021] see figure 1 , figure 2 , image 3 , Figure 4 and Figure 5, waste glass bottle recycling production line, including chain plate conveyor (1), bottle feeding and capping turntable (2), capping machine (3), sorting control box (4), cylinder pusher (5), turning guide rail (6), residual liquid collection box (7), crushing and washing machine box (8), telescopic rods (11) are arranged on both sides of the chain conveyor (1), and the upper part of the chain conveyor (1) A glass closed baffle (12) is provided, an adjustable bracket (13) is provided at the bottom of the chain conveyor (1), and an elongated baffle (111) is welded at one end of the telescopic rod (11). A rectangular opening (121) is provided on the inner side of the glass sealing baffle (12), a square opening (122) is provided on the outside ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com