Hydraulic valve block lightweight design method based on selective laser melting

A selective laser melting and lightweight design technology, applied in the field of additive manufacturing, can solve problems such as efficiency loss, flow stagnation, and sharp right-angle turns, and achieve the goals of reducing time cost, improving corrosion resistance, reducing pressure loss and energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

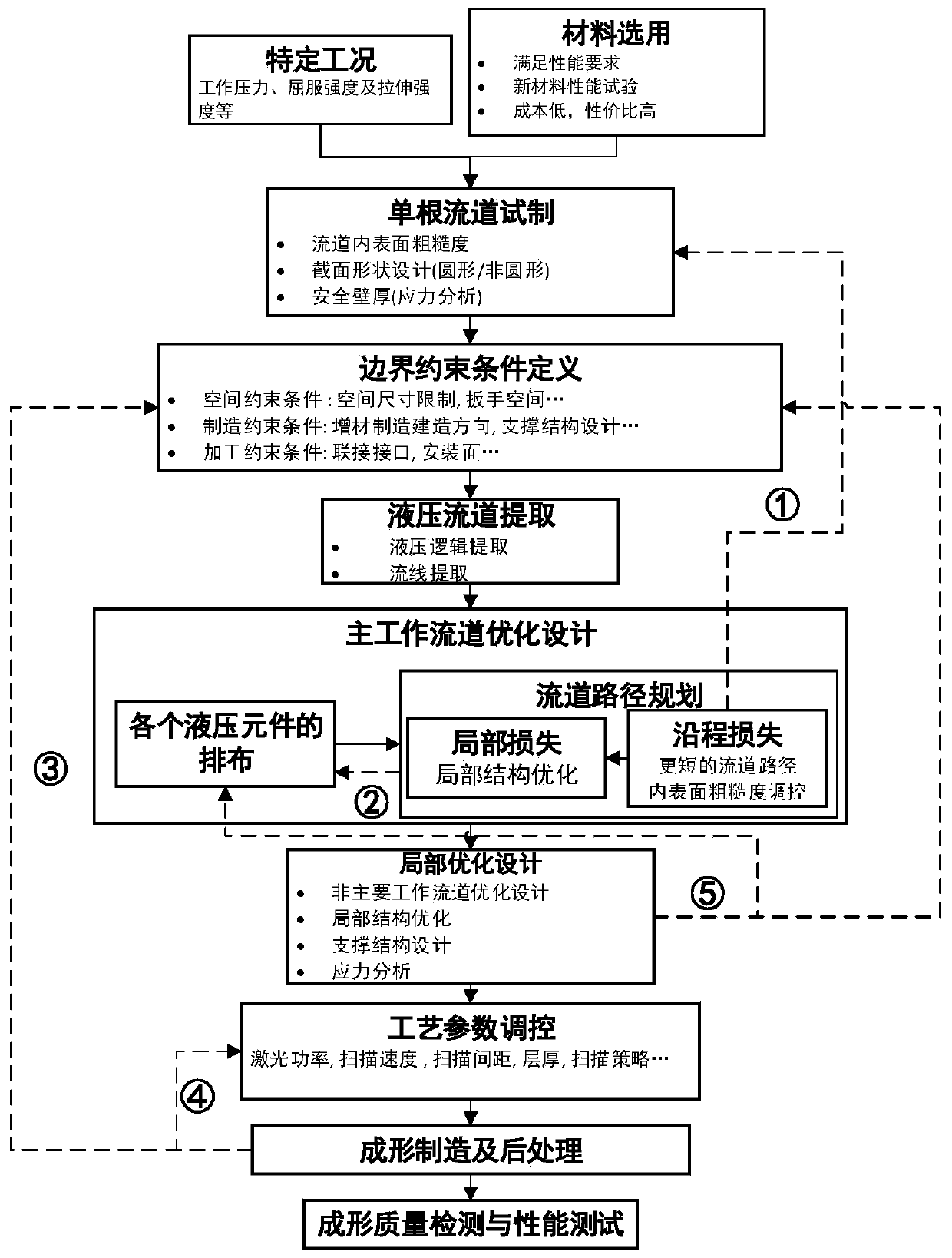

[0037] Regarding the aforementioned and other technical contents, features and effects of the present invention, they will be further described below in conjunction with the accompanying drawings. The hydraulic valve block lightweight design method based on selective laser melting provided by the present invention mainly includes the following steps (such as figure 1 shown).

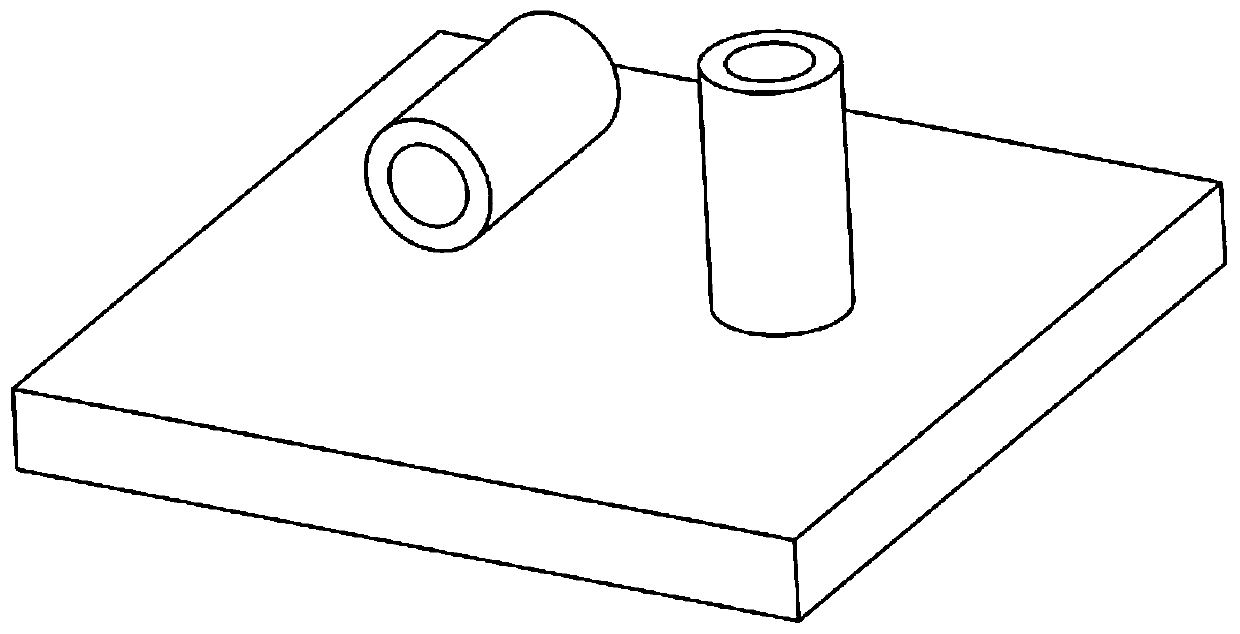

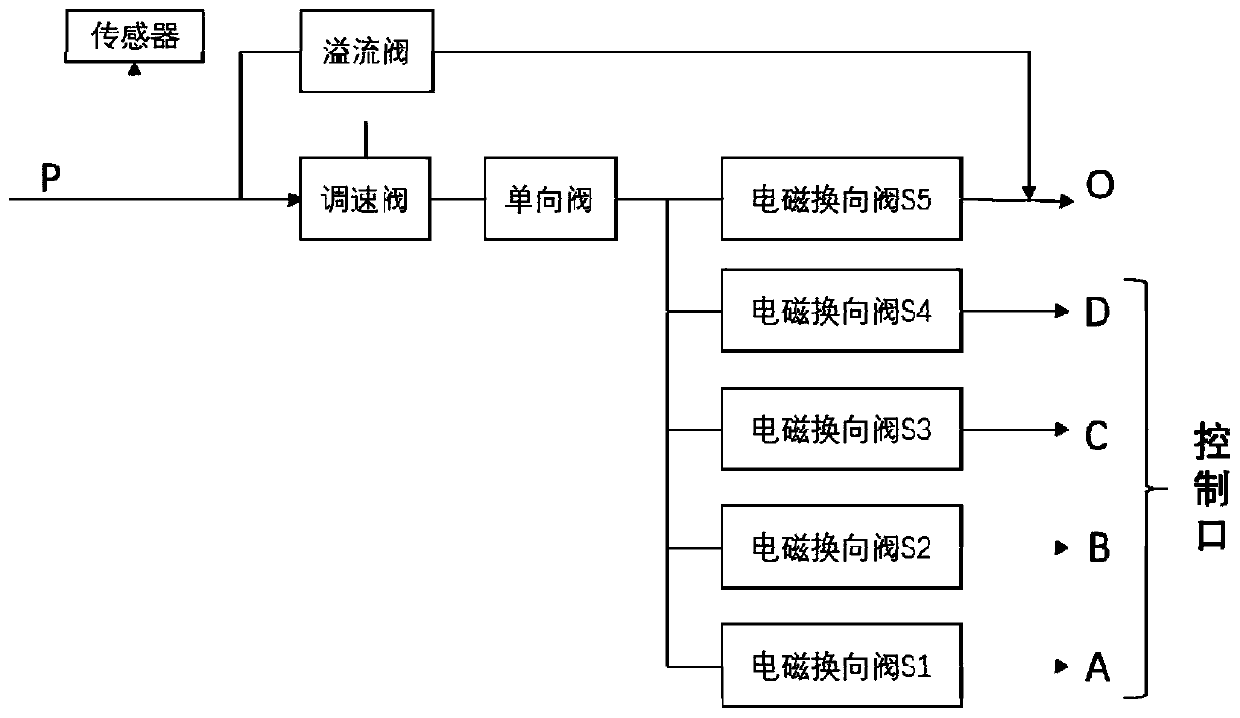

[0038] Taking a specific design case as an example, the requirement is to optimize the additive manufacturing design of the traditional hydraulic valve block (material 45 steel) to ensure that the hydraulic principle, interface, installed valve parts, and functions of the valve block remain unchanged; the material can be changed; the requirements Compared with the valve block of the traditional processing method, after lightweight manufacturing, the weight is reduced by more than 50%, and the volume is reduced by more than 50%, but the functional principle remains the same, and the performance is not redu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com