Preparation process of an explosion-proof magnetostrictive liquid level gauge

A magnetostrictive liquid level and preparation technology, which is applied in the direction of buoy liquid level indicators, etc., can solve the problems of the sharp increase in the cost of magnetostrictive liquid level gauges, the very high straightness requirements of waveguide wires, and the high cost of imported waveguide wires. , to achieve good insulation, high hardness, and reduce storage space and length requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

[0029] The invention provides a preparation process of an explosion-proof magnetostrictive liquid level gauge, comprising the following steps,

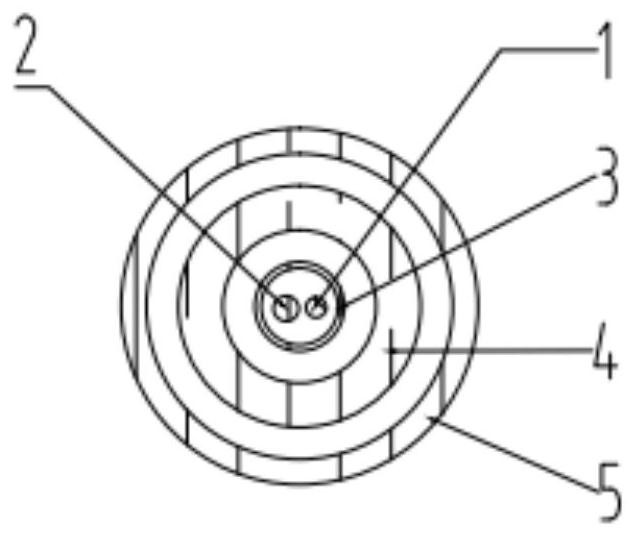

[0030] Step 1): Weld waveguide wire 1 and feeder 2, weld one end of waveguide wire 1 and feeder 2, and penetrate into inner protection tube 3 in parallel, and protect the welding spot of waveguide wire 1 and feeder 2 with a heat shrinkable tube;

[0031] Step 2): Insert the inner protective tube 3 into the bellows 4, and then insert the bellows 4 into the outer protective tube 5;

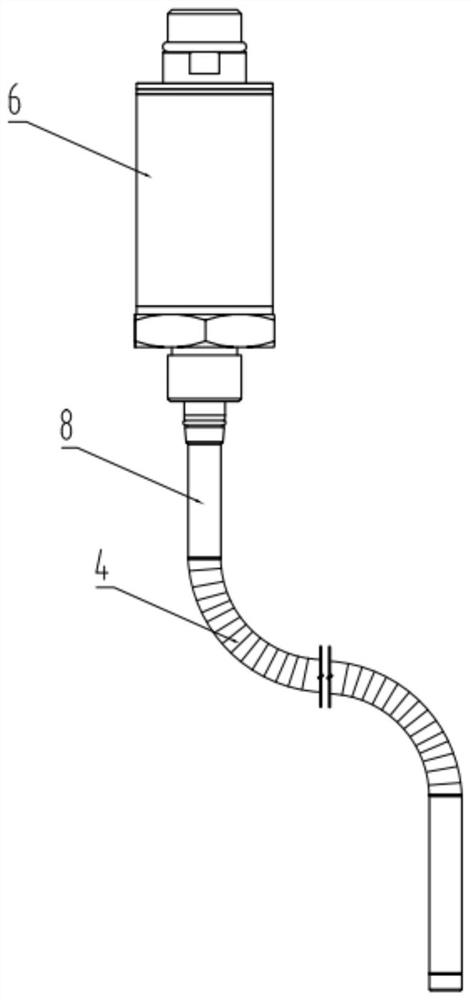

[0032] Step 3): The bellows 4 is welded to the steel pipe 8, and the inner protection tube 3 and the electronic compartment 6 are fixedly connected;

[0033] Step 4): the steel pipe 8 is welded to the electronic warehouse 6;

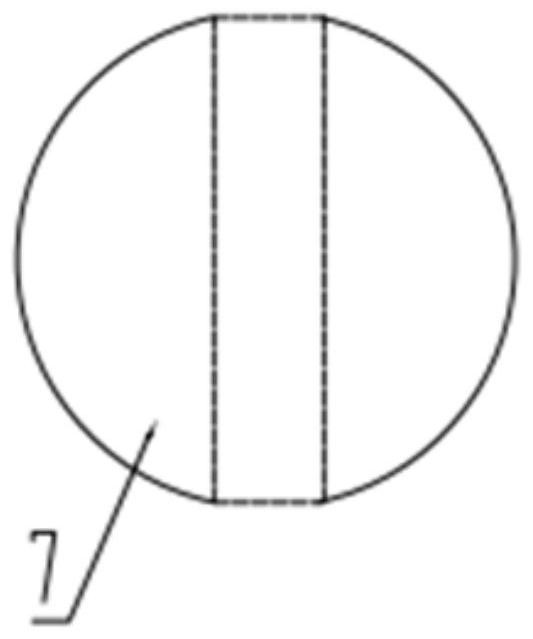

[0034] Step 5) The magnetic floating ball 7 is installed on the outside of the outer protection tube 5. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com