A kind of tofu batch cutting equipment for food processing

A food processing and dicing technology, which is applied in metal processing and other directions, can solve problems such as inability to assemble, low efficiency, and excessive labor, and achieve the effects of reducing workload, reducing work difficulty, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

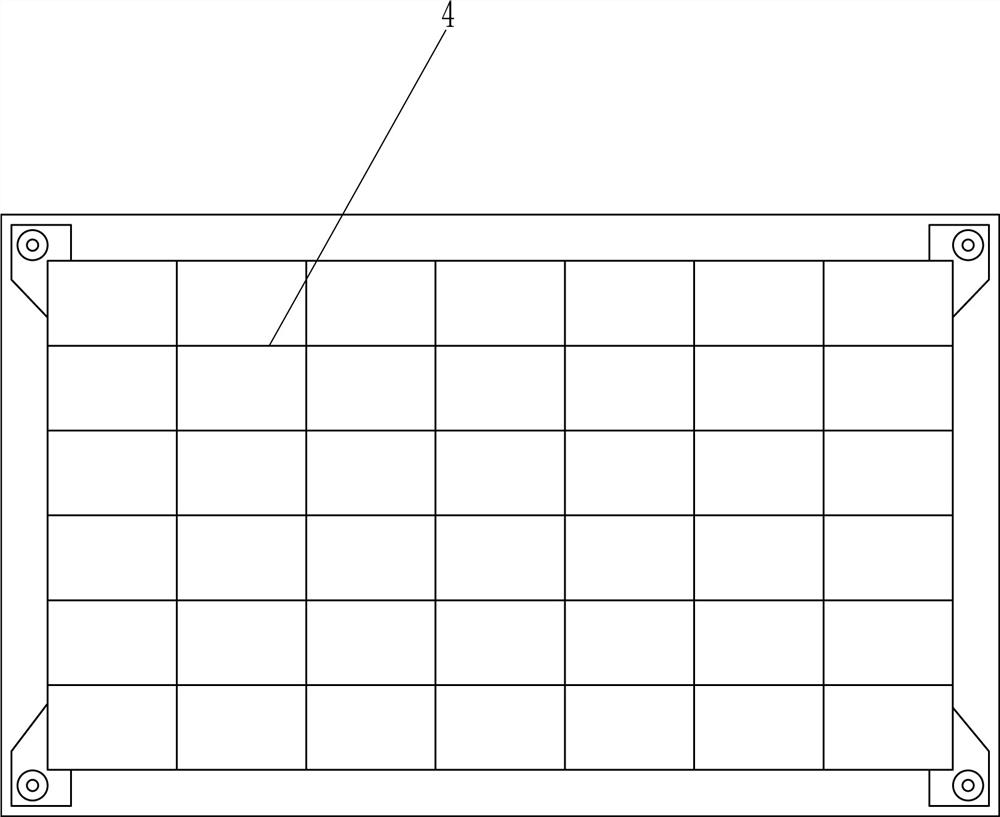

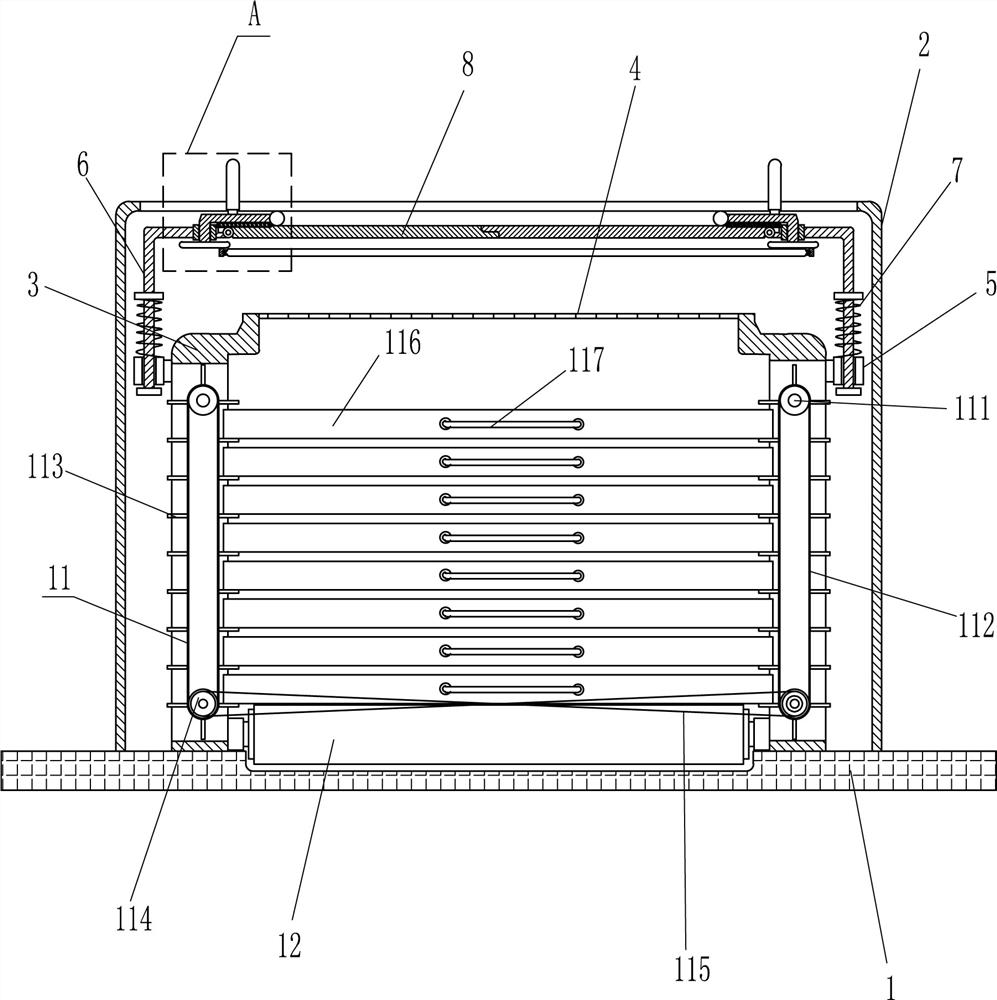

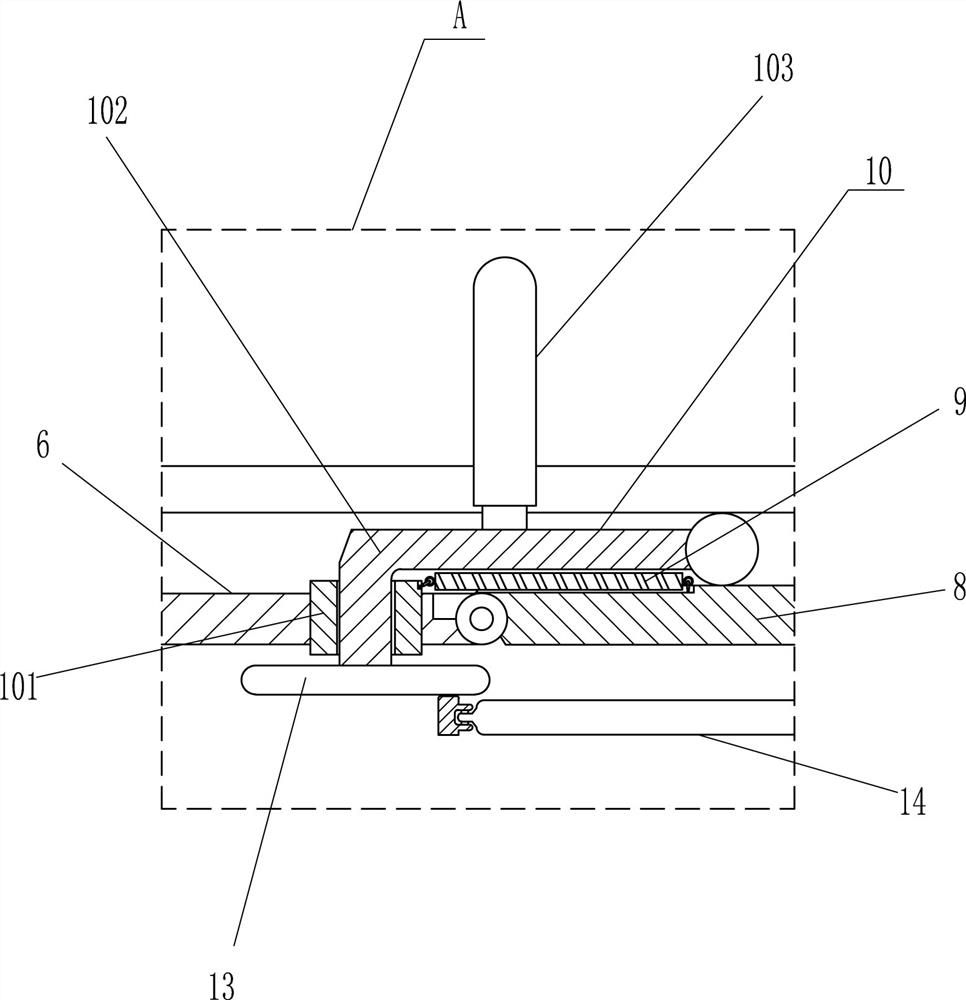

[0018] A kind of tofu batch cutting equipment for food processing, refer to Figure 1-3 , including a base 1, a frame body 2, a support frame 3 and a cut-out grid 4, the top of the base 1 is provided with a frame body 2 and a support frame 3, and the frame body 2 and the support frame 3 are connected to the base 1 by bolts. connection, the support frame 3 is located in the frame body 2, the top of the support frame 3 is provided with a cut-out grid 4, the cut-out grid 4 is parallel to the base 1, and also includes a guide sleeve 5, an L-shaped guide rod 6, an elastic member 7, Pressing plate 8, tension spring 9 and the blocking mechanism 10 that is used to block pressing plate 8, support frame 3 left and right sides are all provided with guide sleeve 5, and the sliding type in guide sleeve 5 is provided with L-shaped guide rod 6, and L-shaped guide An elastic member 7 is connected between the rod 6 and the guide sleeve 5, and the elastic member 7 is set on the outside of the L...

Embodiment 2

[0023] refer to figure 1 , also includes conveying mechanism 11, and conveying mechanism 11 includes roller 111, conveyer belt 112, mounting plate 113, coiling reel 114, stay rope 115, collecting frame 116 and handle 117, and support frame 3 left and right sides are all rotatable design There is a group of rollers 111, two groups of rollers 111 are symmetrical left and right, each group has two rollers 111, the two rollers 111 are arranged symmetrically up and down, the lower right roller 111 is equipped with a motor, the output shaft of the motor is connected with the roller 11 through a coupling connection, each set of rollers 111 is wound with a conveyor belt 112, and the left and right conveyor belts 112 are evenly spaced with installation plates 113, and the front sides of the rollers 111 on the left and right sides below are provided with winding reels 114, and the left and right sides are wound A stay cord 115 is intersected between the reels 114, and a collection frame...

Embodiment 3

[0026] refer to figure 1 , also includes a belt conveyor 12, the bottom of the base 1 is equipped with a belt conveyor 12, and the belt conveyor 12 is located below between the left and right conveyor belts 112.

[0027] When the tofu is cut into pieces, the collection frames 116 are evenly spaced on the belt conveyor 12, and the belt conveyor 12 is started to run, and the collection frames 116 on the belt conveyor 12 also move forward to the lowest installation position thereupon. Between the plates 113, the mounting plates 113 on the left and right sides hold up the collection frame 116 on the belt conveyor 12. In this way, the workers only need to place the collection frames 116 on the belt conveyor 12 one by one, which reduces the work difficulty and further improves the work efficiency.

[0028] refer to image 3 , also includes a disc 13 and a connecting rod 14, the bottom of the L-shaped clamping rod 102 is provided with a disc 13, and a connecting rod 14 is rotationa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com