Surfactant for wax removal of mobile phones and preparation method thereof

A technology for surfactants and mobile phones, applied in the direction of surface-active detergent compositions, non-ionic surface-active compounds, chemical instruments and methods, etc., can solve the problems of good wax removal ability of wax-removing surfactants and small corrosion of mobile phone shells , to achieve the effect of protection from corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of a kind of mobile phone dewaxing surfactant described in the embodiment of the present invention comprises the following steps:

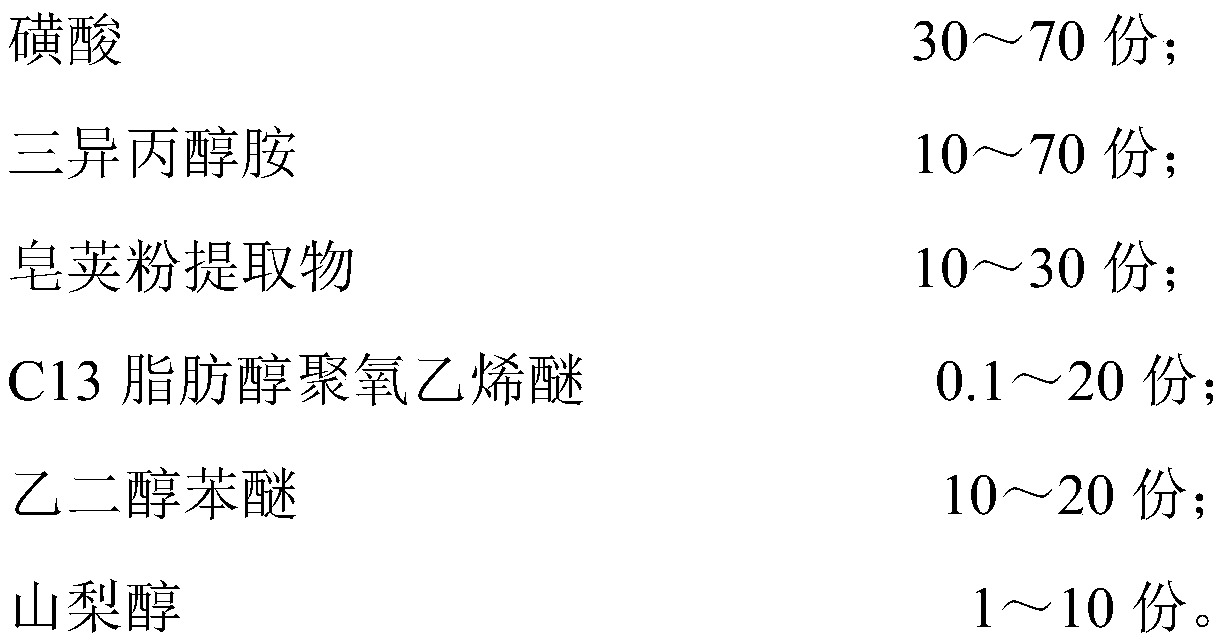

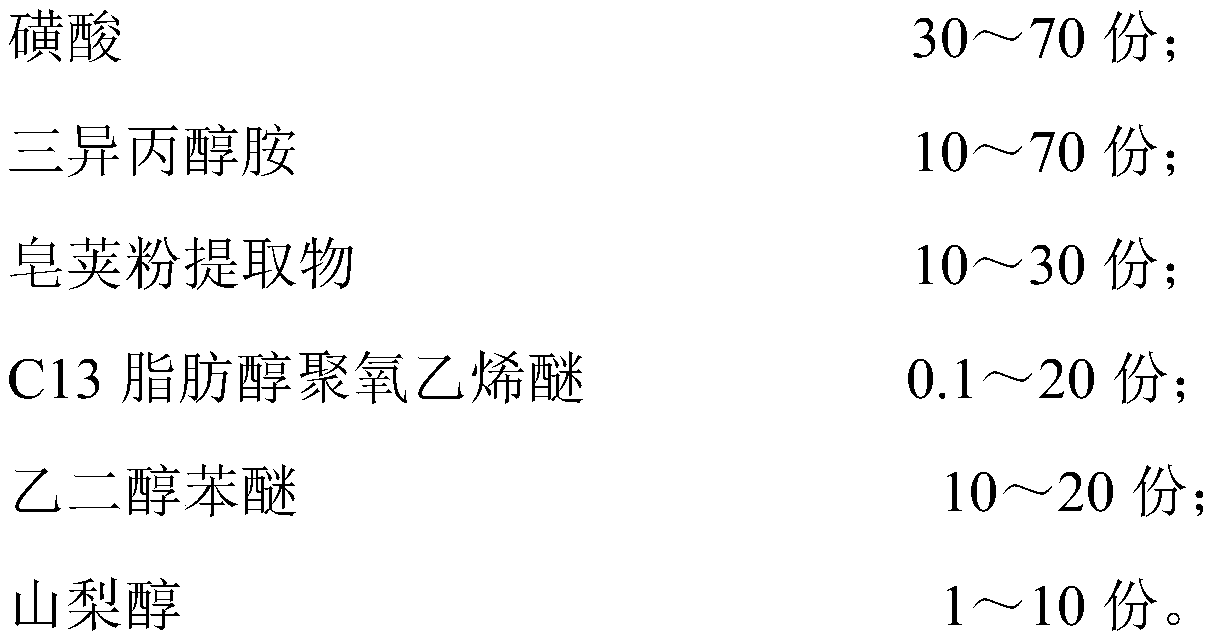

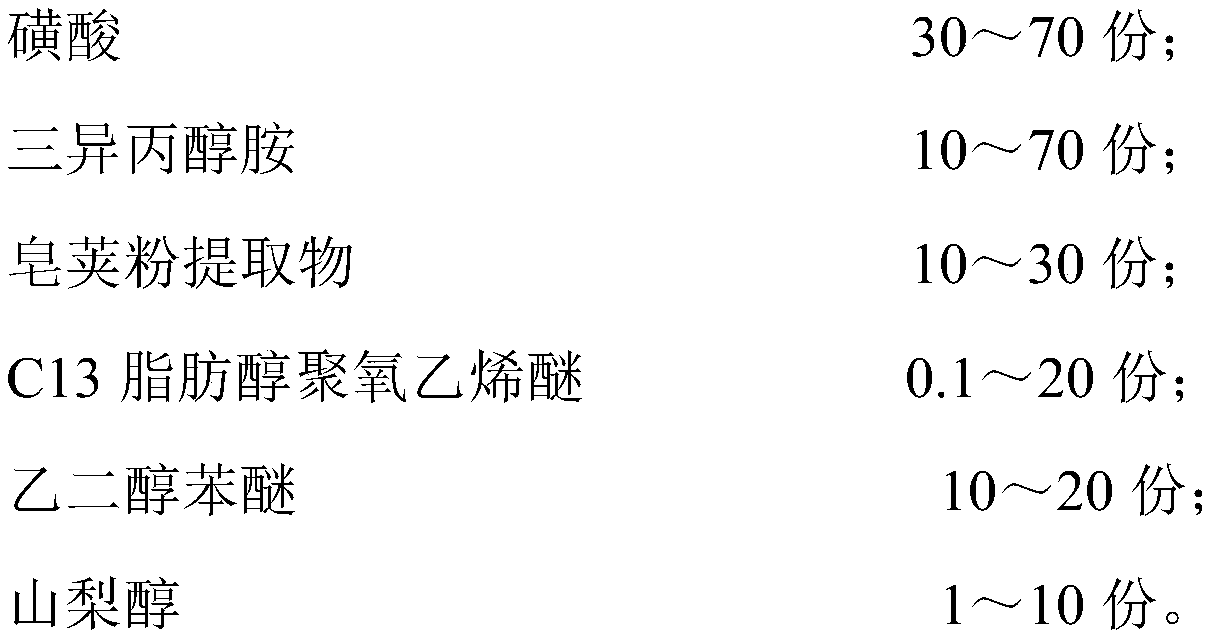

[0041] Step S100, sequentially add sulfonic acid, saponins powder extract, C13 fatty alcohol polyoxyethylene ether, ethylene glycol phenyl ether and sorbitol into the reaction kettle, and fully stir.

[0042] Step S200, adding triisopropanolamine to adjust the pH value of the mixture in the reactor to a preset pH to form a reactant.

[0043] Specifically, the preset pH is 7-8, preferably, the preset pH is 7.5-7.8.

[0044] Further, while stirring, triisopropanolamine is added to adjust the pH value of the mixture in the reactor to a preset pH, and the stirring speed is 60-100 rpm.

[0045] Step S300 , after stirring the reactants evenly, heating and heat preservation is carried out, and after a predetermined time of heat preservation, the water is distilled out under reduced pressure to obtain the finished product. ...

specific Embodiment 1

[0049] Add 30 parts of sulfonic acid, 30 parts of acacia powder extract, 20 parts of C13 fatty alcohol polyoxyethylene ether, 19 parts of ethylene glycol phenyl ether and 1 part of sorbitol in the reactor; the rotating speed of the reactor is 90 rpm Minutes, where the EO number of C13 fatty alcohol polyoxyethylene ether is 3. Use triisopropanolamine to adjust the pH value of the mixture in the reaction kettle to be constant at 7.5-8, while stirring continuously; after stirring evenly, heat to 110°C, and then fully react for 3 hours, and distill the water under reduced pressure at the same time to obtain finished product. During the whole reaction process, the temperature is not lower than 85°C, otherwise it needs to be heated to between 85°C and 110°C.

specific Embodiment 2

[0051] The difference from the specific example 1 is that there are 40 parts of sulfonic acid, 8 parts of C13 fatty alcohol polyoxyethylene ether, 1 part of ethylene glycol phenyl ether and 0.2 part of sorbitol. The EO number of C13 fatty alcohol polyoxyethylene ether is 8, and the pH value is 7.5-8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com