Snow-melting agent with corrosion inhibition effect on carbon steel and preparation method thereof

A snow-melting agent and corrosion-inhibiting technology, applied in the field of snow-melting agent preparation, can solve the problems of high price and lack of widespread adoption, and achieve the effect of protection from corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

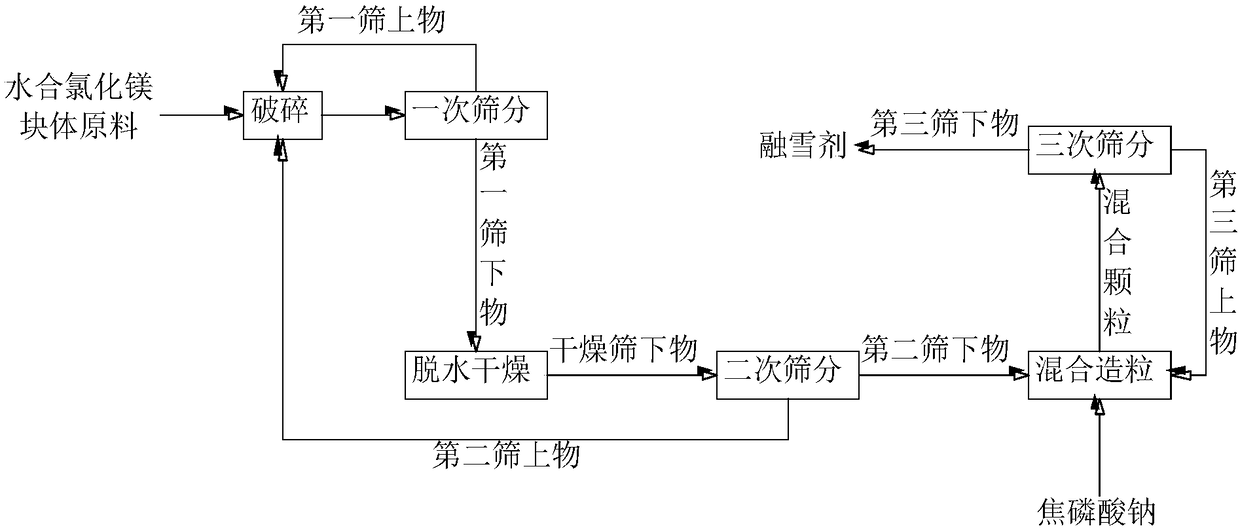

[0028] The following combination figure 1 The process route diagram in illustrates the preparation method of the above-mentioned deicing agent of the present invention; Specifically, the preparation method comprises the following steps:

[0029] In step S1, the bulk magnesium chloride hydrate raw material is crushed to a particle size of 2 cm to 5 cm, and then sieved once to obtain a first oversize and a first undersize.

[0030] Specifically, the aperture of the sieve used for primary screening is 20 mesh to 40 mesh.

[0031] Here, the raw material of the hydrated magnesium chloride block is preferably bischofite; in this way, using a large amount of bischofite as a by-product of the salt lake as a raw material, on the one hand, greatly reduces the preparation cost of the deicing agent, and on the other hand, can also reduce a large amount of by-product water. The imbalance of salt lake resources caused by chlormagnesite.

[0032] Preferably, the first sieve material needs ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com