A kind of inorganic fiber material automatic spraying system and method

An automatic spraying and inorganic fiber technology, which is applied in the processing of textile materials, the processing of textile material carriers, and the continuous processing of textile materials. It can solve the problems of uneven spraying of fiber materials, improve spraying uniformity and improve motion stability. , The effect of uniform thickness of the spray

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

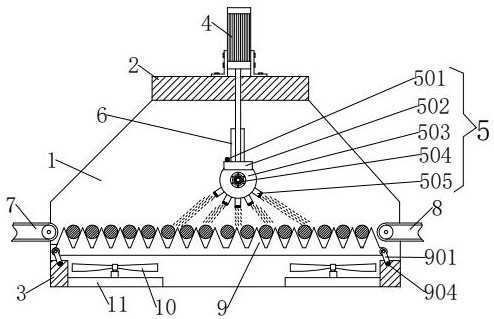

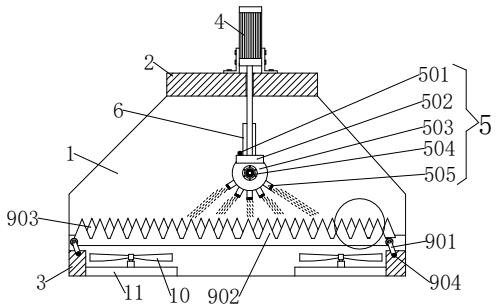

[0039] see Figure 1-3 as well as Figure 6-7 , is an inorganic fiber material automatic spraying system, comprising a frame 1, the frame 1 is set as a conical block structure, the frame 1 is set as a plate structure upright on the ground, and the top of the frame 1 is provided with a top support plate 2, The top support plate 2 is arranged horizontally on the top of the frame 1, the middle position of the front wall of the frame 1 is provided with a chute 6 standing upright on the ground, and the bottom end of the frame 1 is provided with a bottom support seat 3, and the bottom support seat 3 has a total of There are two pieces, symmetrically fixed on the left and right sides of the rack 1;

[0040] A linear push rod motor 4 is installed on the top of the top support plate 2, and a push rod protrudes downward from the bottom end of the linear push rod motor 4, and the push rod extends downward through the top support plate 2, and the bottom end of the push rod is installed Th...

Embodiment 2

[0053] see Figure 1-7 , is a schematic diagram of the overall structure of an automated spraying system for inorganic fiber materials. This embodiment has similarities with the contents of the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences are:

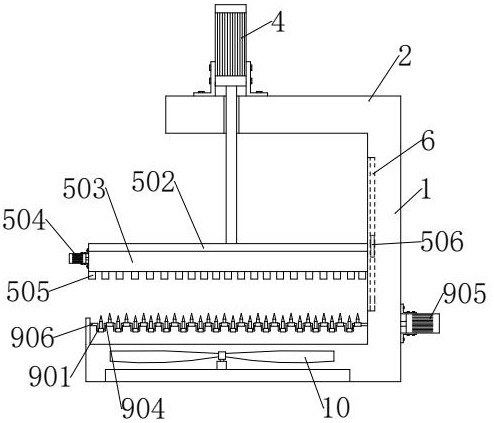

[0054] Spraying device 5 comprises sprayer top cover 502, sprayer housing 503, sprayer housing 503 is made as cylindrical structure, sprayer housing 503 is vertical with frame 1, and the top of sprayer housing 503 is provided with horizontal structure The sprayer top cover 502, the top of the sprayer top cover 502 is provided with a liquid injection interface 501, and the bottom of the sprayer housing 503 is provided with a plurality of equally spaced spray nozzles 505;

[0055] The interior of the sprayer housing 503 is provided with a mixing chamber 506, the liquid injection interface 501 communicates with the mixing chamber 506, the mixing chamber 506 is set as...

Embodiment 3

[0059] see Figure 8 , is a flow chart of an automatic spraying method for inorganic fiber materials, which automatically sprays the surface of fiber ropes made of inorganic fiber materials, including the following steps:

[0060] S1, material preparation, cutting the fiber rope made of inorganic fiber material to obtain fiber ropes of equal length;

[0061] S2. Putting in materials, spread the cut fiber rope horizontally on the conveyer belt in step S1, and put the fiber rope under the spraying device 5 through the conveyer belt;

[0062] S3, the spraying process, the fiber rope in step S2 is sent to the top of the conveying turning mechanism 9 through the second conveyor belt 8, and the conveying turning mechanism 9 stirs the fiber rope to roll under the spraying device 5, and the spraying device 5 sprays downward Spraying, the spraying is evenly sprinkled on the surface of the fiber rope, and the surface of the fiber rope is sprayed;

[0063] S4, spraying is completed, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com