Self-lubricating type scroll plate and manufacturing method thereof

A manufacturing method and scroll technology, which are applied to rotary piston pumps, rotary piston machines, rotary piston/swing piston pump components, etc., can solve the problem of reducing performance and service life, reducing compressor work efficiency, Problems such as poor scroll lubrication effect, to achieve the effect of improving self-lubrication, prolonging service life, and high wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

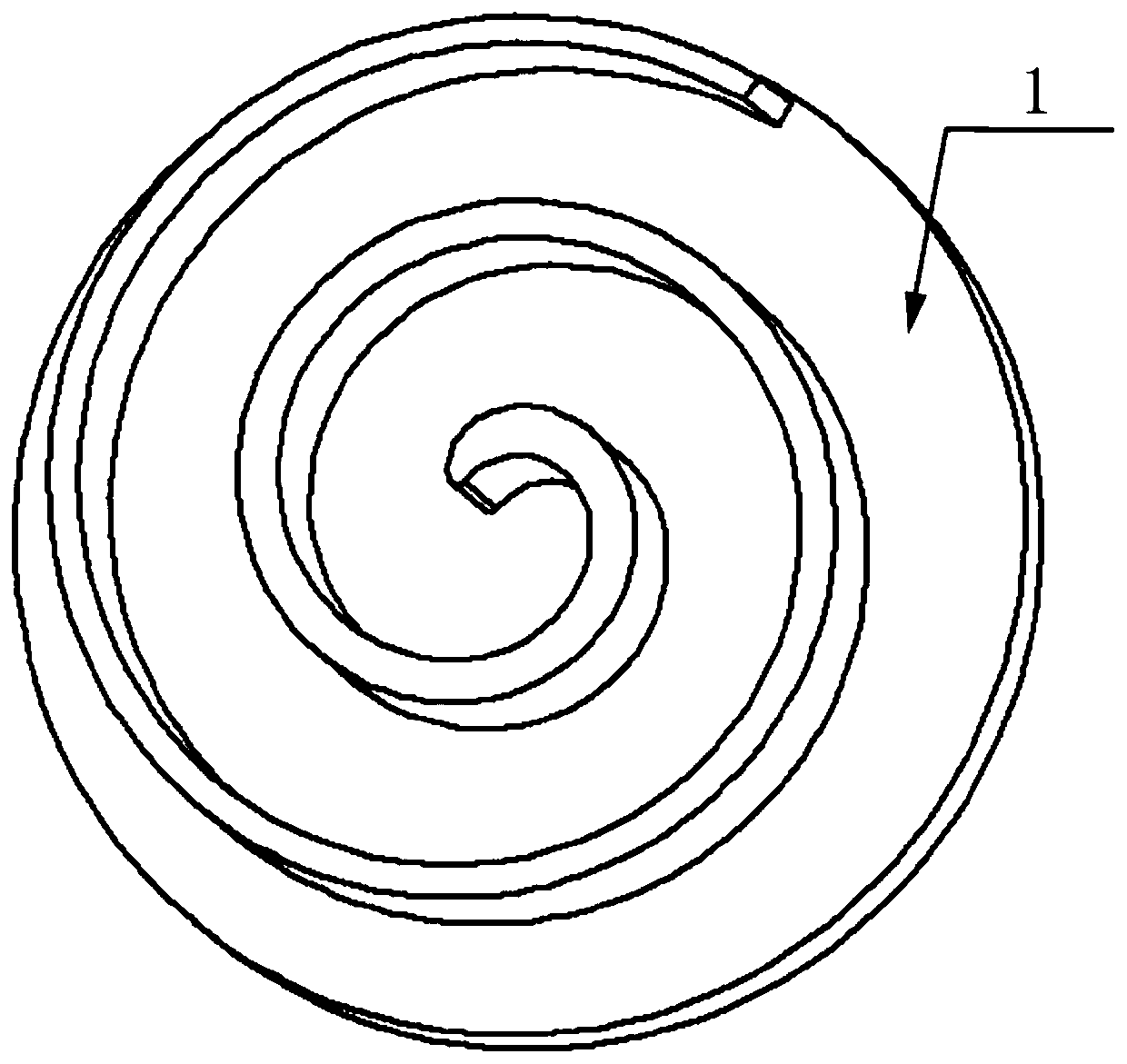

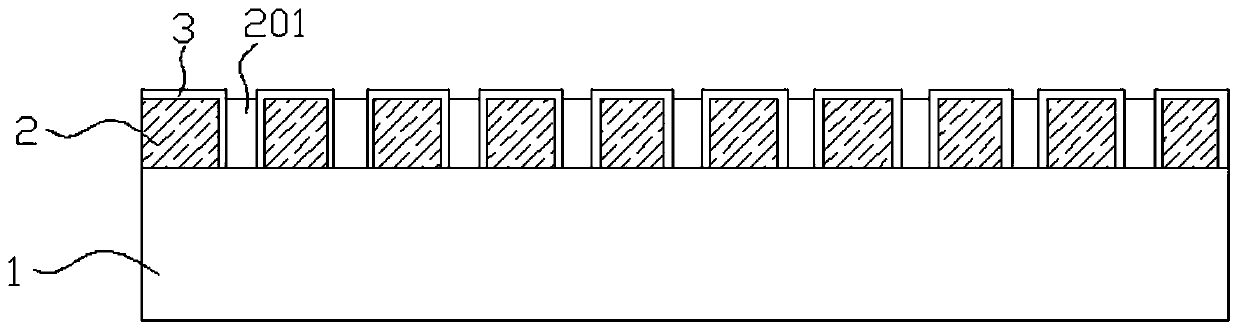

[0031] Such as Figure 1-2 As shown, a self-lubricating scroll includes a scroll body 1, an oxide film 2 is provided on the outer surface of the scroll body, and a plurality of corrosion holes 201 are provided on the oxide film. The pores are honeycomb-shaped with a diameter of 400nm. The hardness of the oxide film is 500HV, which has high wear resistance. The ratio of the corrosion hole depth to the thickness of the oxide film is 1:1 (that is, no sealing treatment), and the oxide film The thickness is 40 μm, and the outer surface of the oxide film is provided with a self-lubricating coating 3 to improve the self-lubrication of the scroll and prolong the service life. The thickness of the self-lubricating layer is 20 μm, which has good anti-friction and wear-resisting properties.

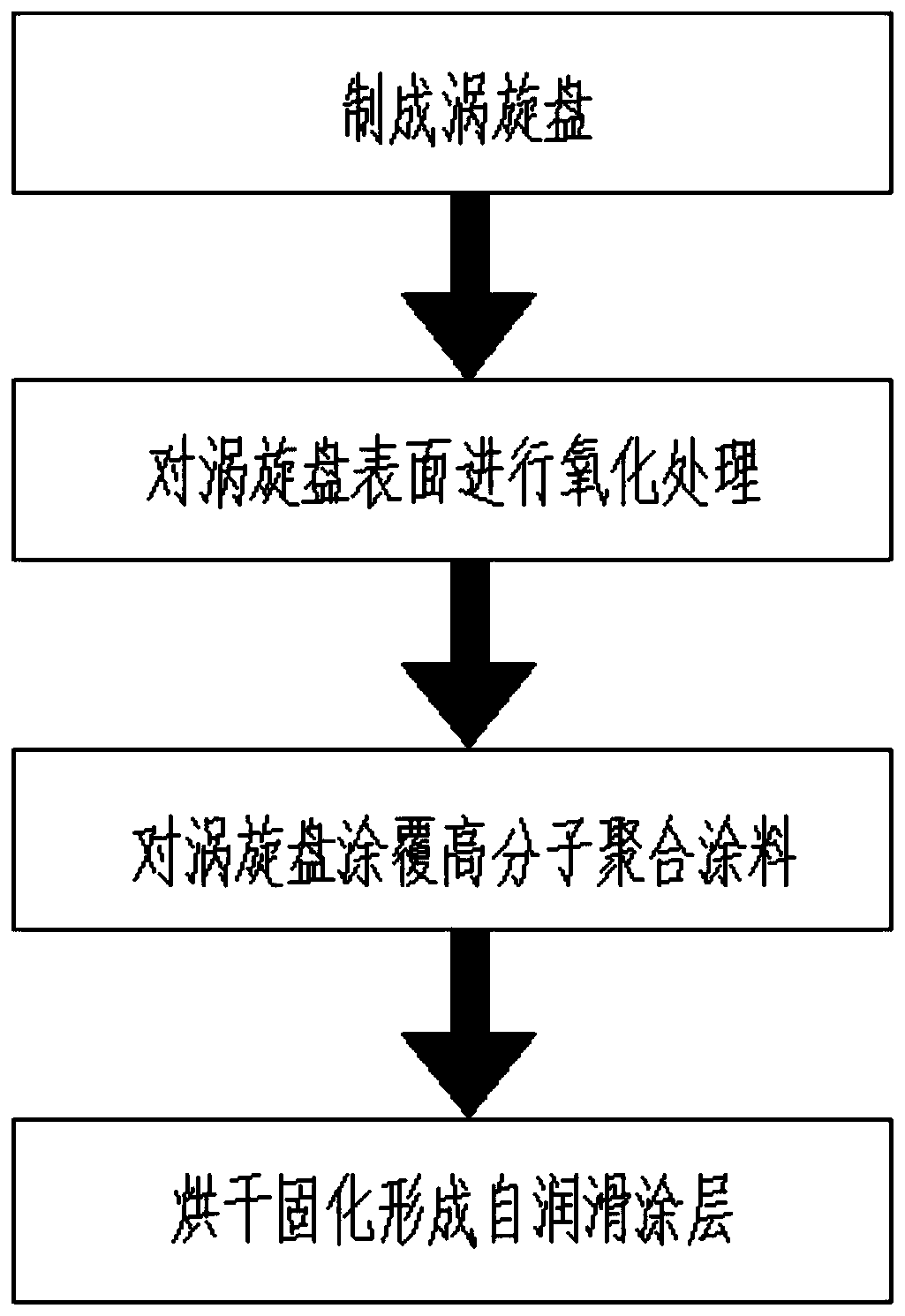

[0032] Such as image 3 Shown, a kind of manufacturing metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com