Monitoring work support system for an iron and steel plant

A support system, a technology for steel plants, applied in general control systems, manufacturing computing systems, control/regulation systems, etc., can solve problems such as difficulty in learning data, reduce abnormal omissions, facilitate operations, and achieve high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0035] (system structure)

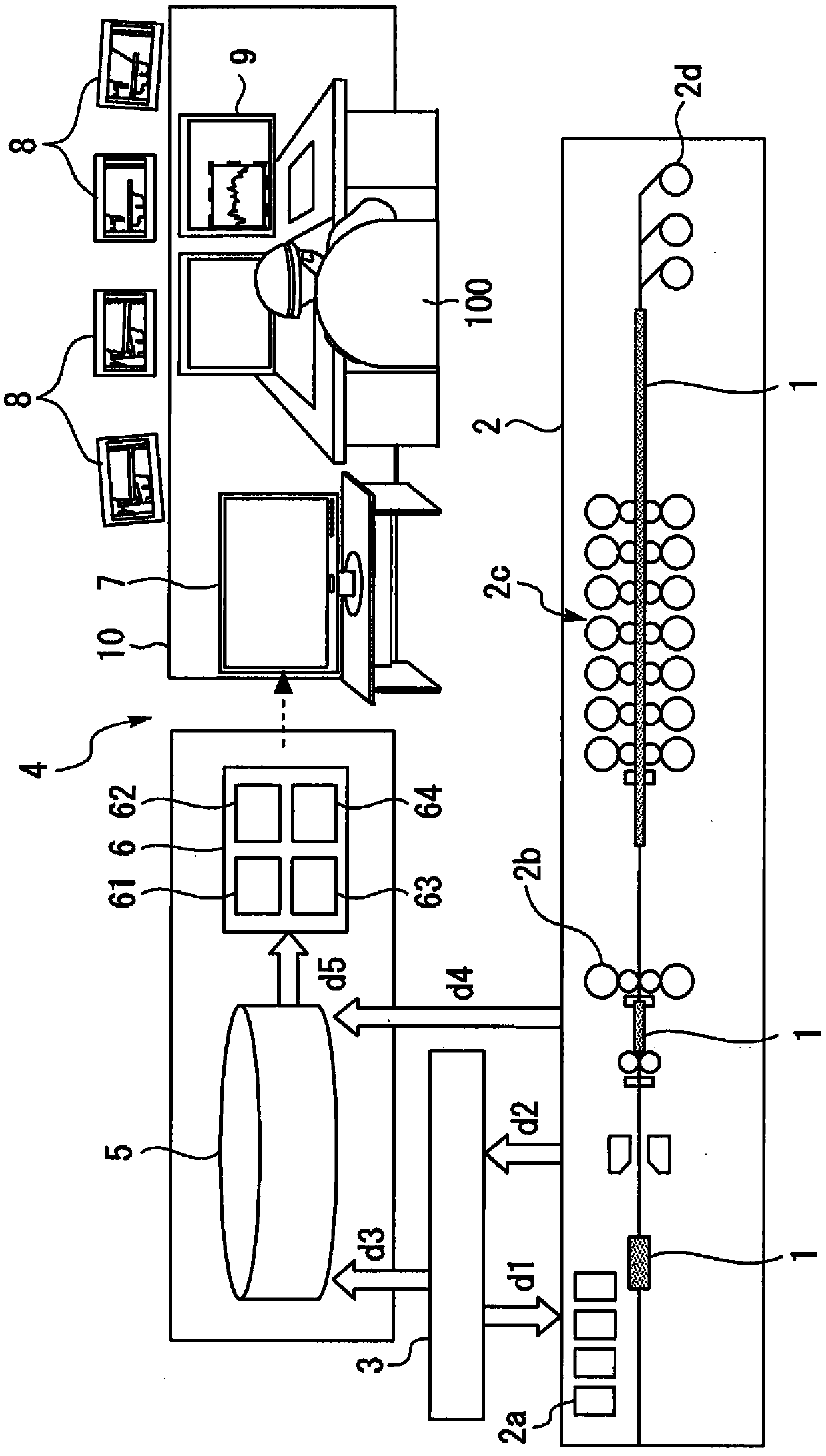

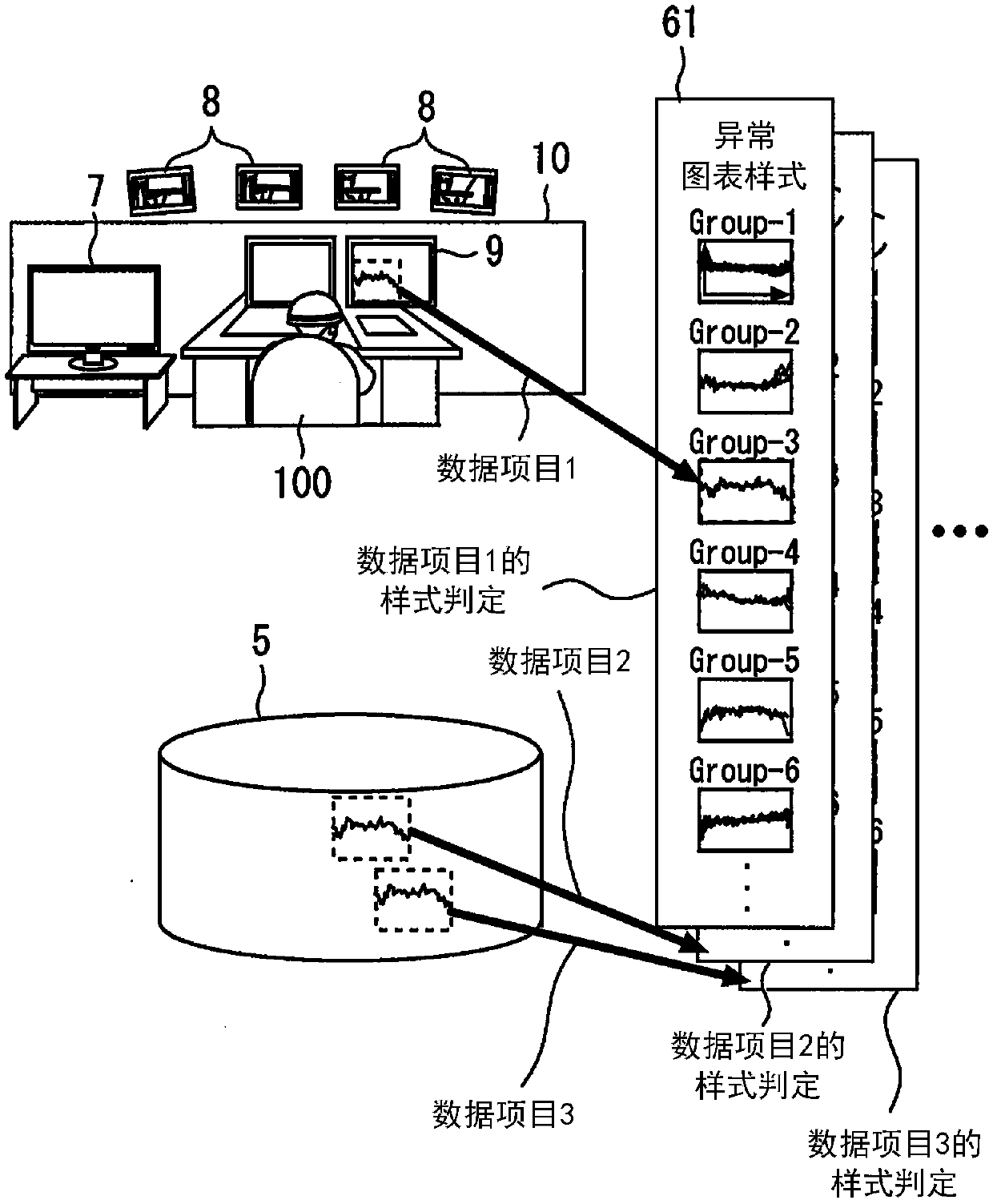

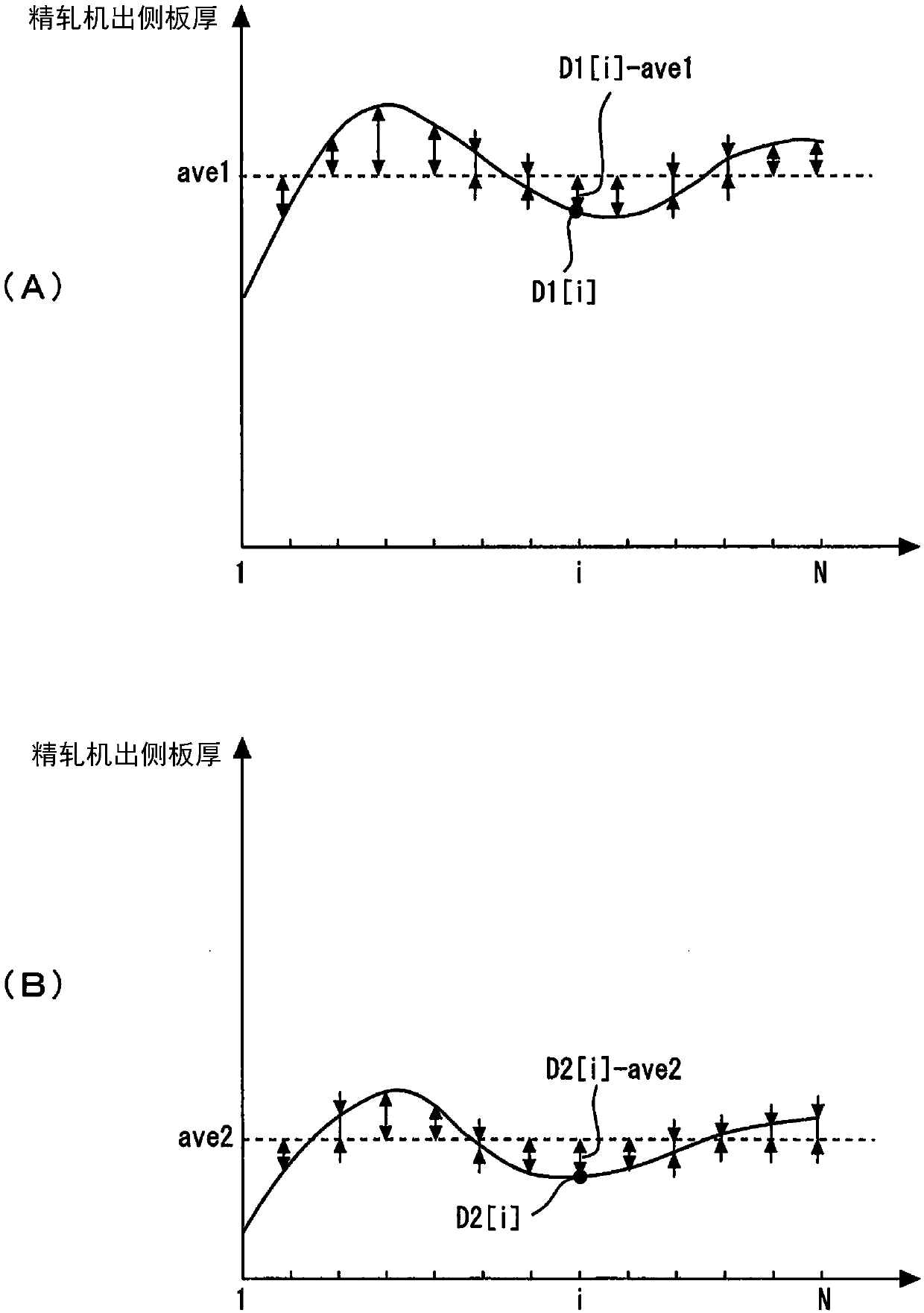

[0036] figure 1 It is a schematic diagram showing the data flow used in steel plants and systems to which the surveillance operation support system is applied.

[0037] In the rolling line 2, the high-temperature thick plate (to-be-rolled material 1) heated by the heating furnace 2a is conveyed by conveying rolls, and processed while stretching to a target plate thickness in the rough rolling mill 2b and finishing rolling mill 2c. The plate is widened and cooled, and finally coiled by the coiler 2d to produce a product (coil).

[0038] The control system 3 transmits command data d1 for operation to each equipment of the rolling line 2 . In addition, sensors are installed on each equipment of the rolling line 2, and the control system 3 collects measured actual data through them. Actual data are broadly divided into two types: actual data d2 used in the control system 3 and actual data d4 used for analysis or evaluation without being used by the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com