High-performance crystalline silicon battery assembly and solar battery panel

A crystalline silicon cell, high-performance technology, applied in the field of solar photovoltaics, which can solve the problems of complex layout, long bus bars, and difficult handling.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

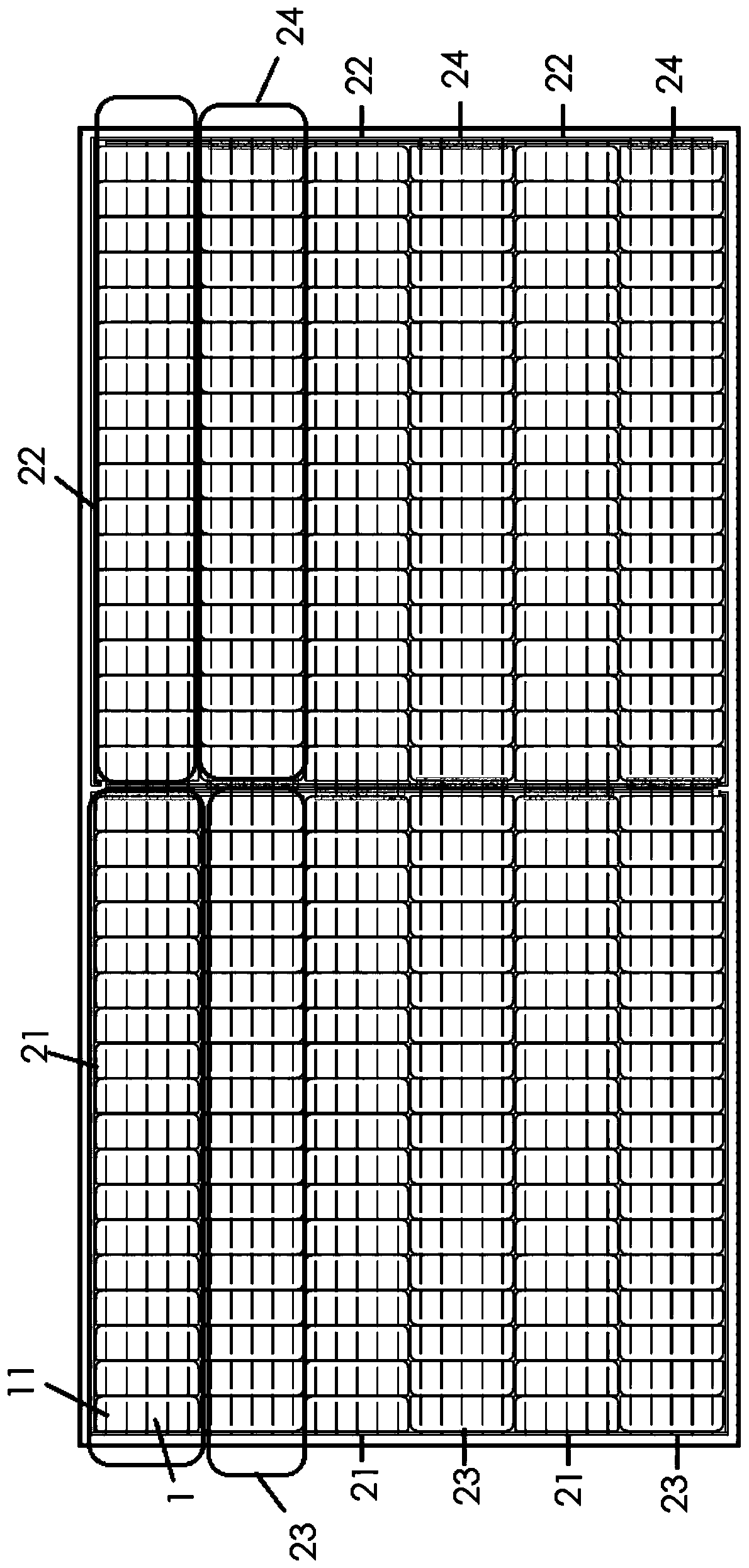

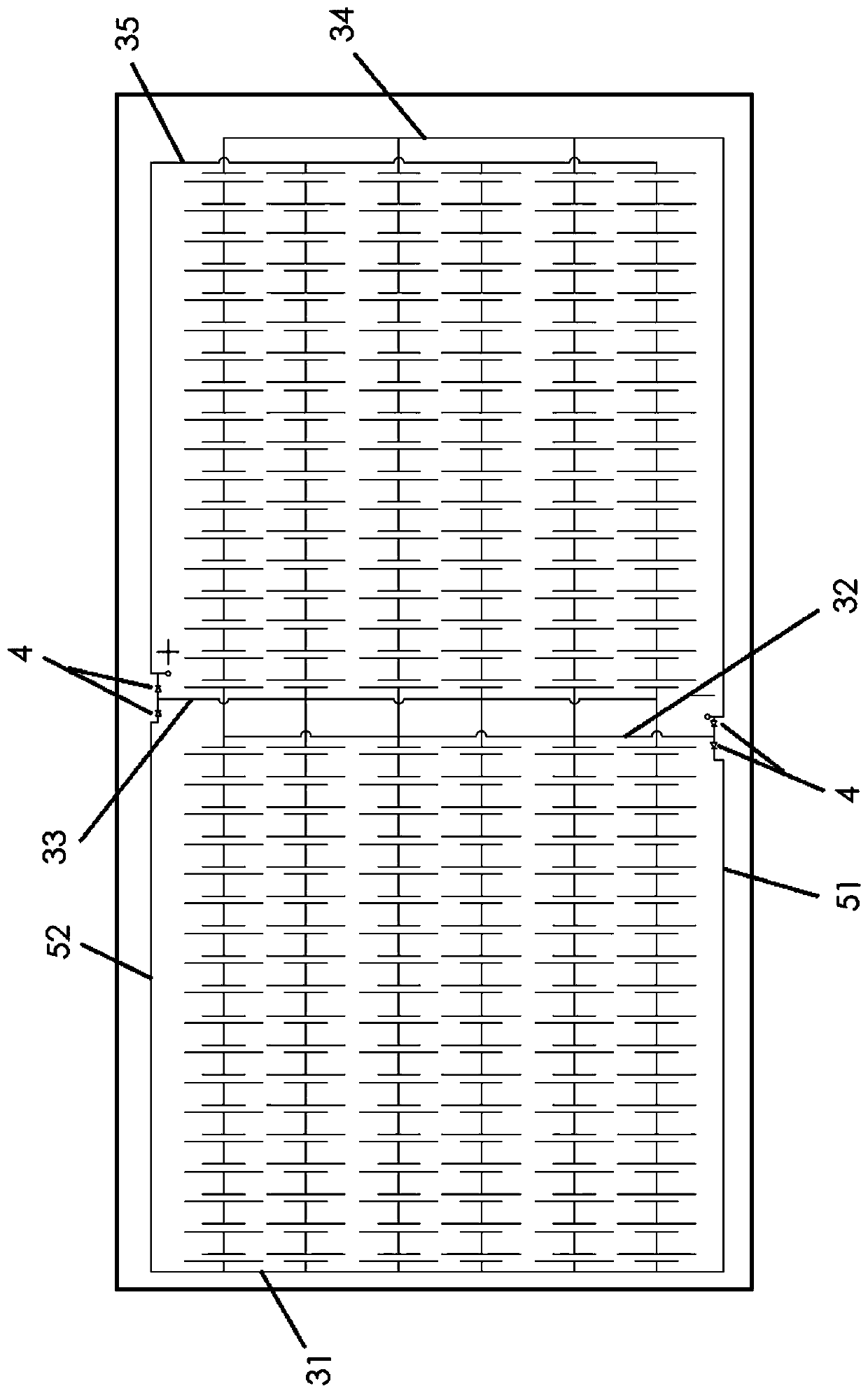

[0070] Embodiment one, such as Figure 1-3 As shown, the first longitudinal bus bar 31 is electrically connected to the fourth longitudinal bus bar 34 through the first transverse bus bar 51, and two diodes 4 are arranged in series on the first transverse bus bar 51;

[0071] The second longitudinal bus bar 32 is electrically connected to the conductive part between the two series diodes 4 arranged on the first transverse bus bar 51;

[0072] The first longitudinal bus bar 31 is electrically connected to the fifth longitudinal bus bar 35 through the second transverse bus bar 52, and two diodes 4 are also arranged in series on the second transverse bus bar 52;

[0073] The third longitudinal bus bar 33 is electrically connected to the conductive part between the two series diodes 4 arranged on the second transverse bus bar 52;

[0074] The lengths of the first transverse bus bar 51 and the second transverse bus bar 52 are parallel to the long sides of the crystalline silicon b...

Embodiment 2

[0076] Embodiment two, such as Figure 4-6 As shown, the first longitudinal bus bar 31 is electrically connected to the fifth longitudinal bus bar 35 through the third transverse bus bar 53 and the fourth transverse bus bar 54 in turn, and two diodes 4 are arranged in series on the fourth transverse bus bar 54 ;

[0077] The third longitudinal bus bar 33 is electrically connected to the conductive part between the two series diodes 4 arranged on the fourth transverse bus bar 54;

[0078] The first longitudinal bus bar 31 is electrically connected to the fourth longitudinal bus bar 34 through the third transverse bus bar 53 and the fifth transverse bus bar 55 in turn, and two diodes 4 are also arranged in series on the fifth transverse bus bar 55;

[0079] The second longitudinal bus bar 32 is electrically connected to the conductive part between the two series diodes 4 arranged on the fifth transverse bus bar 55;

[0080] The lengths of the third transverse bus bar 53, the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com