Boron and nitrogen doped carbon porous nanotube coated platinum alloy nanoparticle material catalyst and preparation method and application thereof

A nanoparticle, nitrogen-doped carbon technology, applied in chemical instruments and methods, physical/chemical process catalysts, ozone preparation, etc., can solve the problems of high catalyst cost and low catalytic efficiency, and achieve the effect of simple preparation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

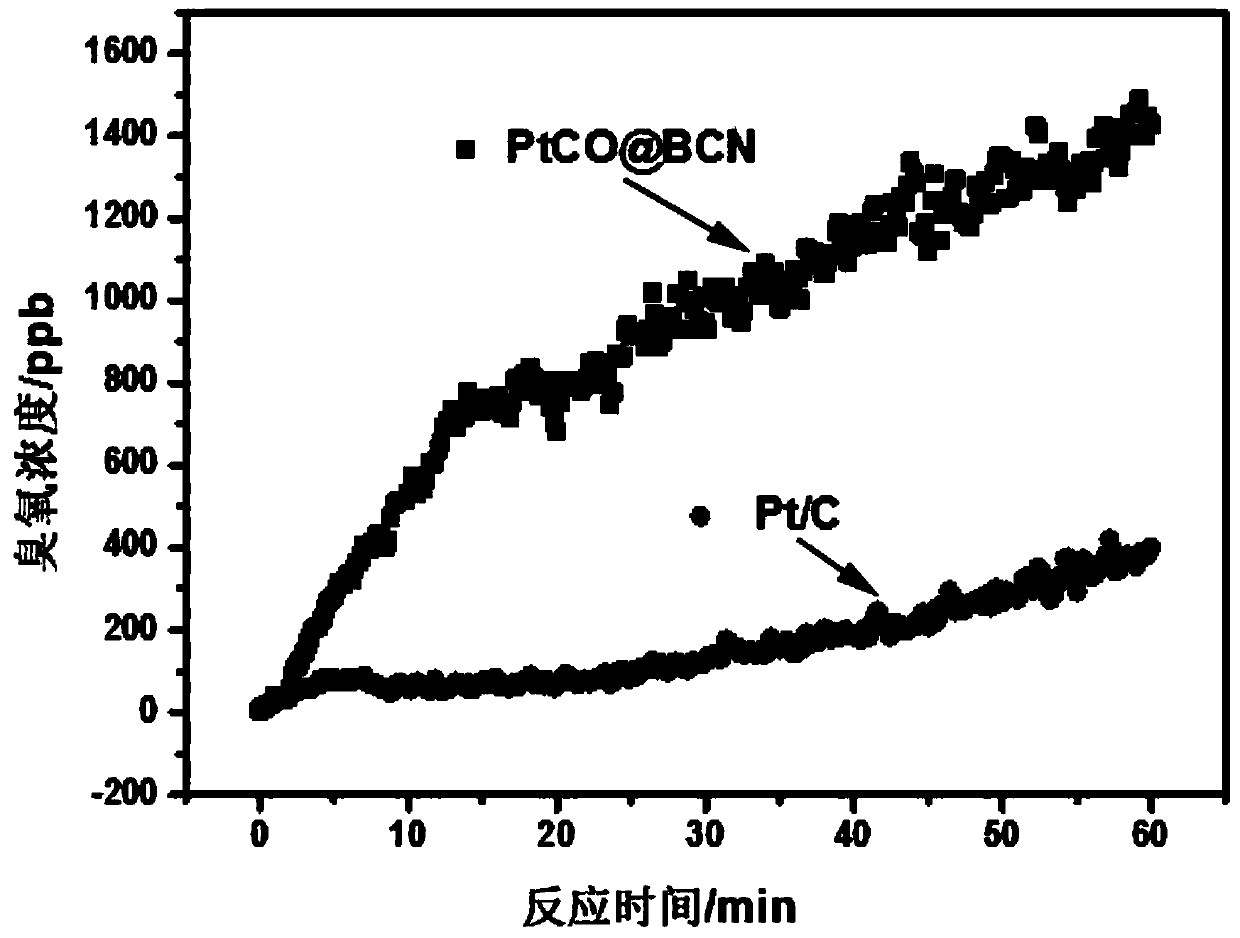

[0029] Example 1: Synthesis of PtCo@BCN catalyst and its electrocatalytic preparation of ozone

[0030] 1) Dissolve 0.15 g of boric acid, 5 g of urea, 0.5 g of polyethylene glycol, 0.013 g of cobalt acetylacetonate, and 0.015 g of platinum acetylacetonate into 50 mL of water, and disperse uniformly by ultrasonic, stir at room temperature for 1 hour, and mix the obtained solution Transfer to an oven and dry at 80°C for 24 hours to completely evaporate the water in the solution to obtain a solid mixture;

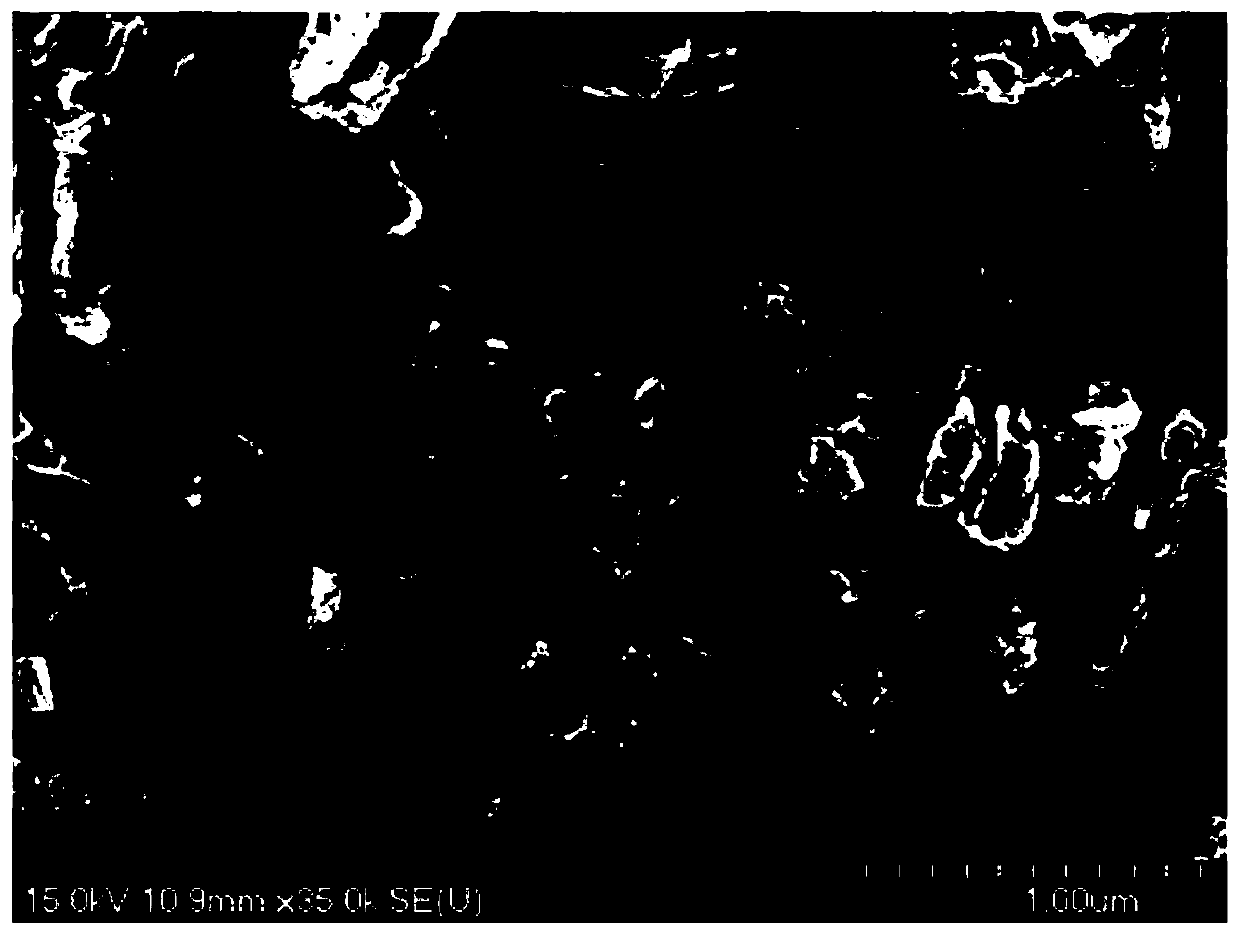

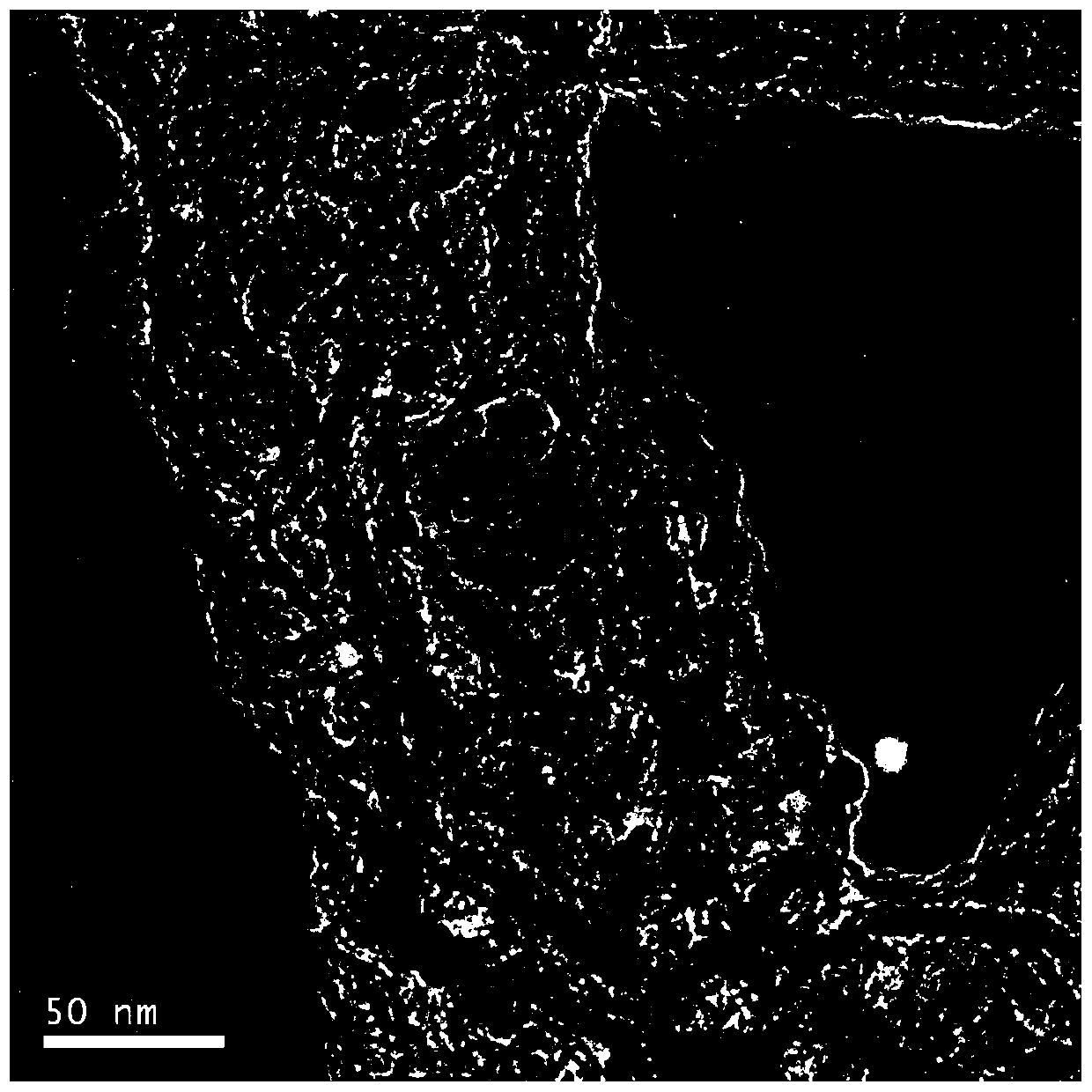

[0031] 2) Place the solid mixture obtained in step 1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min in a nitrogen atmosphere, and calcinate at 900°C for 6 hours to obtain boron and nitrogen doped Carbon porous nanotube-coated platinum alloy nanoparticle material catalyst, marked as PtCo@BCN catalyst (the PtCo@BCN catalyst was characterized by BET, and the specific surface area was 865 square meters per gram). The SEM image of the...

Embodiment 2

[0036] Example 2: Synthesis of PtNi@BCN catalyst and its electrocatalytic preparation of ozone

[0037] 1) Dissolve 0.15 g of boric acid, 5 g of urea, 0.5 g of polyethylene glycol, 0.01 g of nickel acetylacetonate, and 0.015 g of platinum acetylacetonate into 50 mL of water, and disperse uniformly by ultrasonic, stir at room temperature for 1 hour, and mix the obtained The solution was transferred to an oven and dried at 80°C for 24 hours to completely evaporate the water in the solution to obtain a solid mixture;

[0038] 2) Put the solid mixture obtained in step 1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and calcinate at 900°C for 6 hours to obtain boron and nitrogen doped A carbon porous nanotube coated platinum-nickel alloy nanoparticle material catalyst.

[0039] The catalytic performance of the PtNi@BCN catalyst prepared in Example 2 was tested, the specific method is as follows:

[0040]...

Embodiment 3

[0042] Example 3: Synthesis of PtFe@BCN catalyst and its electrocatalytic preparation of ozone

[0043] 1) Dissolve 0.15 g of boric acid, 5 g of urea, 0.5 g of polyethylene glycol, 0.013 g of iron acetylacetonate, and 0.015 g of platinum acetylacetonate into 50 mL of water, and disperse evenly by ultrasonication. The solution was transferred to an oven and dried at 80°C for 24 hours to completely evaporate the water in the solution to obtain a solid mixture;

[0044] 2) Put the solid mixture obtained in step 1) in a tube furnace, raise the temperature from room temperature to 900°C at a rate of 5°C / min under a nitrogen atmosphere, and calcinate at 900°C for 6 hours to obtain boron and nitrogen doped Carbon porous nanotube coated platinum-iron alloy nanoparticle material catalyst.

[0045] The catalytic performance of the PtFe@BCN catalyst prepared in Example 3 was tested, the specific method is as follows:

[0046] Weigh 8 mg of the prepared PtFe@BCN catalyst particles, mix ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap