Movable disk saw

A circular saw, mobile technology, applied in circular saws, portable motorized circular saws, other motorized reciprocating sawing machines, etc. Low coefficient and the effect of reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

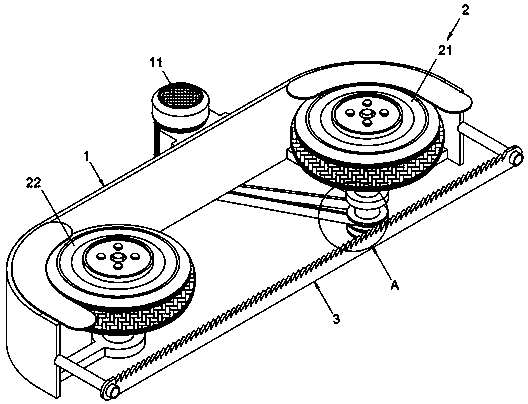

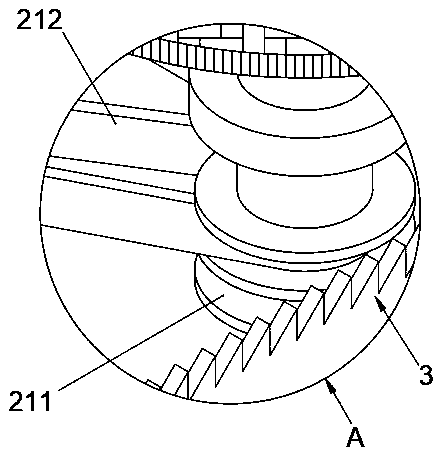

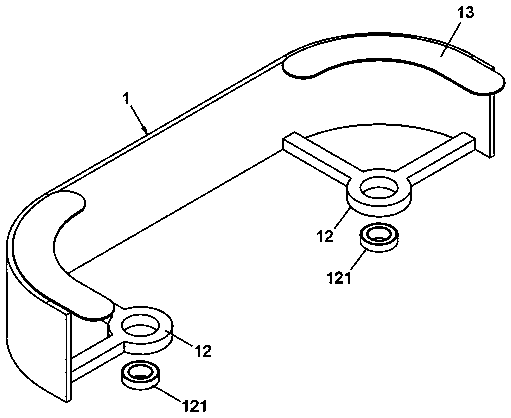

[0029] A mobile circular saw such as Figure 1-Figure 6 As shown, including the console 1, the outer surface of the console 1 is equipped with a motor 11, and two fixed rings 12 are symmetrically arranged in the console 1, and the fixed rings 12 are fixedly connected with the inner wall of the console 1, and the two fixed A transmission mechanism 2 for conveying wood is provided between the rings 12. The transmission mechanism 2 includes a first wheel 21 and a second wheel 22, and the motor 11 provides driving for the first wheel 21. The front end of the transmission mechanism 2 is provided with a saw blade 3, The saw blade 3 cuts the wood transmitted by the transmission mechanism 2 , and both ends of the saw blade 3 are fixedly connected with the console 1 .

[0030] In this embodiment, the entire operating table 1 is made of stainless steel, which has good wear resistance and corrosion resistance, and has the advantages of stable structure and low cost, which prolongs its se...

Embodiment 2

[0039] Such as Figure 7 As shown, one end of the connecting rod 31 is welded with a screw 311 , both ends of the saw blade 3 are provided with a through hole 32 , and one end of the screw 311 passing through the through hole 32 is threadedly connected with a threaded cap 312 .

[0040] In this embodiment, the kerf of the saw blade 3 will become blunt due to long-term production operations. To replace it, it is only necessary to remove the threaded cap 312 from the screw rod 311, and then remove the saw blade 3, which is easy to operate and easy to replace.

[0041]When the mobile circular saw of the present invention is in use, the motor 11 is connected to an external power source to make it work, and the motor 11 is connected with the controller to realize the reciprocating motion of forward rotation and reverse rotation, and the wood to be cut will be cut one by one. The side is attached to the outer surface of the first wheel 21 and the second wheel 22, and the two wheels ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com