Conveyor convenient to disassembly and move

A technology for conveyors and auxiliary conveyor belts, which is applied in the field of conveyors that are easy to disassemble and move, and can solve the problems of narrow width, large occupied space, and inconvenient movement, so as to reduce power consumption, reduce occupied space, and save transportation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

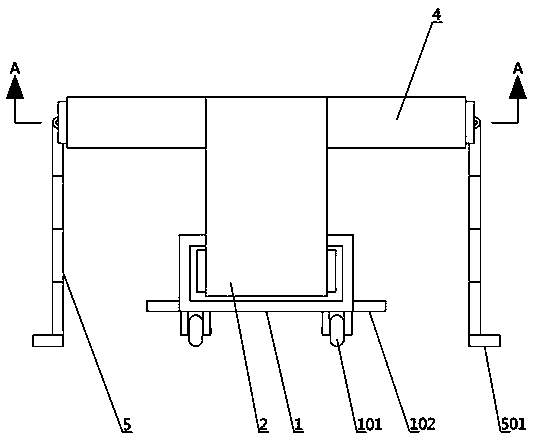

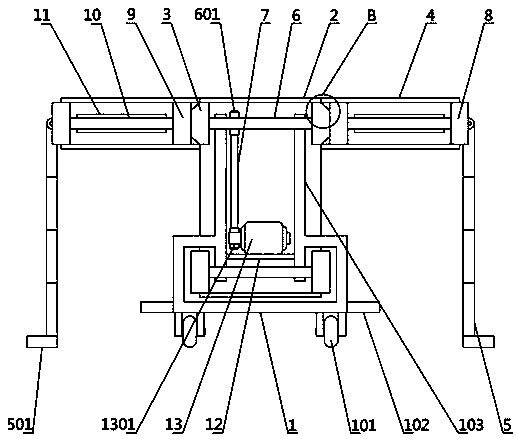

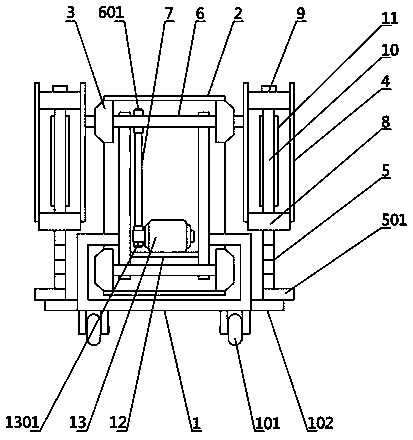

[0026] see Figure 1-8 , the present invention provides a technical solution: a conveyor that is easy to disassemble and move, including a base 1, a main conveyor belt 2, two auxiliary conveyor belts 4 and legs 5, the main body of the base 1 is open at the front and rear ends, and the upper A box structure with an opening in the middle of the side, the lower side of the base 1 is provided with a moving wheel 101, the left and right sides of the base 1 are provided near the lower end with a supporting plate 102 for supporting the load-bearing plate 501 at the lower end of the leg 5, and the upper middle opening of the base 1 is provided. There are two first support plates 103 parallel to each other, the four ends of the first support plate 103 are respectively connected to the four horizontally placed first rotating shafts 6, and both ends of the first rotating shaft 6 pass through the first supporting plate 103 at the corresponding position, And both ends of the first rotating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com